- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic ring

Results for

Magnetic ring - Import export

STRONG MAGNETS GMBH

Germany

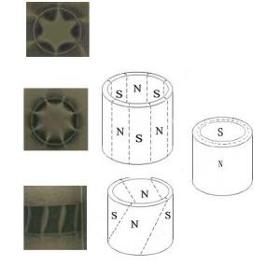

Neodymium ring magnet ais also known as tube magnet, a round disc magnet with a straight hole along the centre, the hole in centre ensures great versatility. Most ring magnet is with north and south poles on the flat circular surfaces (this is called as axial magnetisation). The few exception that is diametrically magnetised is specifically marked. Also, Multi pole ring magnet, even radially magnetized ring magnet, is more and more referred in this industry now. Ring magnet is being designed into a new generation of motors, generators, hydraulic cylinders, pumps & sensors, rotor shafts and more. What's more, it remains very popular in high end loud speakers and high intensity separators. We are ready to make a custom ring magnet for your application, welcome to contact us for a further communication.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The temperature indicated refers to the maximum operating material temperature. However, that value can be reduced according to geometry.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The temperature indicated refers to the maximum operating material temperature. However, that value can be reduced according to geometry.

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

The temperature indicated refers to the maximum operating material temperature. However, that value can be reduced according to geometry.

Request for a quote

SIKO GMBH

Germany

A combination of the MSAC506 magnetic sensor and the MRAC506 magnetic ring forms a system for absolute angle measurement. The MSAC506 sensor has an SSI interface with a resolution of 12 Ö 16 bit. There is also an analogue output (1 VSS) with 64 periods for dynamic position tracking. The sensor has an LED for distance monitoring. Magnetic absolute encoder single-turn. Compact design. Resolution 12 … 16 bits. Additional analog Sin/Cos 1 VSS signals. Reading distance ≤1 mm

Request for a quote

SIKO GMBH

Germany

Repeat accuracy of ±1 increment. Status LED display. Works with MR500 magnetic ring, MBR500 magnetic tape ring. Reading distance ≤2 mm. Max. 200000 pulses/revolution in combination with MR500 or MBR500 (160 poles).

Request for a quote

SIKO GMBH

Germany

Max. resolution 0.045° with MR200 or MBR200 (100 poles). Repeat accuracy of ±1 increment. Works with MR200 magnetic ring, MBR200 magnetic tape ring. Reading distance ≤0.8 mm. Max. 4600 pulses/revolution with MBR200 (230 poles).

Request for a quote

SIKO GMBH

Germany

Max. resolution 0.018° with MR320 or MBR320 (250 poles). Repeat accuracy of ±1 increment. Works with MR320 magnetic ring, MBR320 magnetic tape ring. Reading distance ≤2 mm. Max. 5000 pulses/revolution with MR320 or MBR320 (250 poles).

Request for a quote

SIKO GMBH

Germany

High scaling factor ≤64. Pole length 3.2 mm. Speed-proportional signal output. Reading distance ≤2 mm. Works with MB320/1 magnetic tape, MRI01 or MR320 magnetic ring, MBR320 magnetic tape ring. Option: ATEX version withTPS 13 ATEX 47828 001 X EC type-examination certificate.

Request for a quote

SIKO GMBH

Germany

Accuracy class ±0.1°. Status LED display. Works with MBR100 magnetic tape ring. Reading distance ≤0.4 mm. Signal period 1000 μm. Output circuit sin/cos 1 VSS. Robust metal housing.

Request for a quote

SIKO GMBH

Germany

Compact sensor, incremental, digital interface, scaling factor 1250 Profile MSK5000 rotativ: Repeat accuracy of ±1 increment Status LED display Works with MR500 magnetic ring, MBR500 magnetic tape ring reading distance ≤2 mm Max. 200000 pulses/revolution in combination with MR500 and MBR500 (160 poles)

Request for a quote

SIKO GMBH

Germany

Compact sensor, incremental, digital interface, scaling factor 64 Profile MSK210 rotativ: max. resolution 0.045° with MR200 and MBR200 (100 poles) Repeat accuracy of ±1 increment Works with MR200 magnetic ring, MBR200 magnetic tape ring ≤1 mm reading distance Max. 4600 pulses/revolution with MBR200 (230 poles)

Request for a quote

SIKO GMBH

Germany

Compact sensor, incremental, digital interface, scaling factor 64 Profile MSK320 rotativ: max. resolution 0.018° with MR320 and MBR320 (250 poles) Repeat accuracy of ±1 increment Works with MR320 magnetic ring, MBR320 magnetic tape ring reading distance ≤2 mm Max. 5000 pulses/revolution with MR320 and MBR320 (250 poles)

Request for a quote

SIKO GMBH

Germany

Magentic Senosr MSK320 linear Max. resolution 40 μm. Repeat accuracy ±0.04 mm. Works with magnetic tape MB320/1. Reading distance ≤2 mm. Max. resolution 12.5 μm max. resolution 0.006° with MR320 or MBR320 (250 poles) Repeat accuracy ±0.04 mm Repeat accuracy of ±1 increment Works with MB320/1 magnetic tape, MRI01 or MR320 magnetic ring, MBR320 magnetic tape ring Reading distance ≤2 mm Max. 16000 pulses/revolution in combination with MR320 or MBR320 (250 poles) Optionally with reference point R or flexible reference marks FR

Request for a quote

SIKO GMBH

Germany

Incremental, analog interface 1 V SS Profile LE100/1 rotativ: Accuracy class ±0.1° Status LED display Works with MBR100 magnetic tape ring ≤0.4 mm reading distance Signal period 1000 μm Output circuit sin/cos 1 V SS Robust metal housing

Request for a quote

SIKO GMBH

Germany

With flexCoder technology, the MSAC200 can be flexibly adapted to the customer's design and provides precise absolute values with high installation tolerances at the same time. It is basically possible to adapt the encoder and the magnetic ring for precise fitting, for example in motors. An additional feature is the high reading distance ≤0.6 mm and axial tolerance of ±0.2 mm to facilitate the design of the overall system and enable use in dynamic applications. Customer-specific design. Integration into small installation space possible. Absolute resolution up to 21 bit. Repeatability 0.01°. Reading distance ≤0.6 mm. Interface BiSS C, SSI. Optional analog real-time signal output Sin/Cos 1 Vss. Industrial and medical applications e.g., motor feedback, handling automation and robotics.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to an analogue measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. Electrical connection is implemented via a circular connector. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position ring, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a displacement signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a digital measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a digital measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position ring, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a displacement signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to an analogue measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. Electrical connection is implemented via a circular connector. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a digital measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. Electrical connection is implemented via a circular connector. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a digital measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. Electrical connection is implemented via a circular connector. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to a measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The displacement transducers operate according to the principle of run time measurement between two points of a magnetostrictive waveguide. One point is determined by a moveable position magnet, whose distance from the null point corresponds to the section to be measured. The run time of an emitted impulse is directly proportionate to this section. Conversion to an analogue measuring signal takes place in the downstream electronics. The waveguide is housed in a pressure-resistant stainless steel tube or extruded profile. To the rear of this is a die-cast aluminium housing containing the electronics in SMD technology. Electrical connection is implemented via a circular connector. In the rod version, the position magnet is located in a ring, which is guided over the rod without contact. In the profile version, it is located either in a slider, which is linked to the moving part of the machine via a ball joint, or it moves as a liftable position magnet, without wear, over the profile.

Request for a quoteResults for

Magnetic ring - Import exportNumber of results

32 ProductsCountries

Company type