- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining unit

Results for

Machining unit - Import export

EWS WEIGELE GMBH & CO. KG

Germany

EWS goes milling With its latest range of angular heads, EWS brings its trusted technology with new features to machining centres. The system range was presented to the public for the first time at EMO 2015. An elegant design houses high-performance technology, or to put it simply Precision meets Motion. Advantages: the smart solution for compensating for there not being a machining axis Machining hard-to-reach parts Centre boring stepless angle adjustment around the horizontal axis, with tangentially acting double cone clamp MR > 250 Nm Prerequisite: The prerequisite is a "stop block" on the machine. This prevents the entire unit from turning while simultaneously defining the position of the angel of rotation. Variations: basic duplex offset Request form: PDF

Request for a quote

IGUS® GMBH

Germany

-For medium duty use -Minor oil influence -More suitable for indoor applications, but also for outdoor use at temperatures > 5 °C -Unsupported travel distances and up to 20 m for gliding applications -Bus connection cable for machining units/machine tools, handling, indoor cranes

Request for a quote

IGUS® GMBH

Germany

Chainflex® CFKOAX coaxial cables are designed for very heavy duty applications and are almost unlimited resistance to oil, also with bio-oils. Because of its UV resistance, the cables can be used for indoor and outdoor applications. - Unsupported and gliding travel distances up to 400 m and more - Storage and retrieval units for high-bay warehouses, machining units/machine tools, quick handling, cleanroom, semiconductor insertion, indoor cranes, low-temperature applications - For extremely heavy duty applications - Outer jacket: TPE - Hydrolysis and microbe-resistant - Silicone-free - UV-resistant - Oil-resistant according to DIN EN 60811-404, resistant to organic oils according to VDMA 24568 with Plantocut 8 S-MB by DEA

Request for a quote

FÖHRENBACH GMBH

Germany

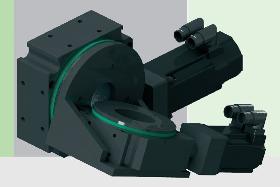

The new designed rotary swivel unit RT2A is the ideal solution for retrofitting your machine with a 4th and 5th axis. It is based on the proven and robust rotary tables of the RT2A series. The design is kept very compact to ensure the best possible use of space with high load capacity. The rotary tables are equipped with an integrated precision roller bearing, which ensures high torque capacity, radial and axial run-out accuracy. The rotary swivel unit RT2A is available in the size variants RT2A150/200 and RT2A100/150. Various stepper or servo motors can be used as drives. In addition, various types of end or reference point switches are available. The swivel range of the swivel axis can be individually defined, the rotary axis can be rotated without limit. Thus the RT2A rotary swivel unit combines all the advantages of a field-proven standard product with the flexibility of a special version.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

coating machine with uv drying unit

Request for a quote

WEBER ULTRASONICS AG

Germany

Utilize Weber Ultrasonics technology for your system just like your application demands it. The innovative and highly modular Saphir machine concept is a breeze to integrate in existing process lines and can be customized to individual requirements. The machine components generator, feed unit, swing unit and Touch-PC with the powerful control software SAPHIR CONTROL 4.0 and extensive accessories are pre-configured and ready for use.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

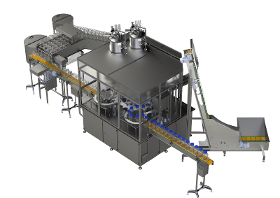

the 888 is a rotary filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines 1400-2100 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste all size ranges

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

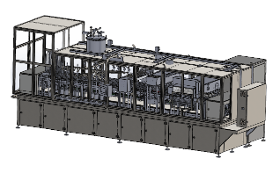

The 200A is linear filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines up to 24,000 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste and molasses in all size ranges.

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

Besthane® treads have 40% lower rolling and swivel resistance than the other polyurethane treads. This means that much less force is required to push or pull transport units carrying heavy loads. It also makes the series particularly interesting for customers focused on ergonomics and occupational safety. Besthane® tread also provides a particularly high level of dynamic load resistance, which is particularly useful when transporting sensitive materials. The tread is typically used for a variety of heavy duty applications on different transport units and machines in the machining and automotive industry. It can provide a load capacity of up to 12,000 kg at high speeds of up to 16 km/h.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4-spindle solution with HSK-A100 on MFZ Machining of the free cut with 4 spindles possible OP 10 and OP 20 are processed in one machine Unit times less than 50s possible

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

Automation has never been so easy! The space miracle from HERMLE enables flexible workpiece handling on only 2 m² - process-safe around the clock. Here, the 6-axis robot unfolds its full automation potential in interaction with the storage unit and machine. Not only the robot has complete freedom of movement, but also the operator. Despite the extremely compact design, nothing is too close, too bulky or too cramped.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

As reliable classic machines, the HM3xx series unites all the outstanding properties of a production crimper. Combining a convincingly solid construction with a high level of user friendliness, and long service life, the HM3xx set a new standard for quality and cost effectiveness. They are compact, powerful and make ergonomic working possible.

Request for a quote

GEDA GMBH

Germany

The transport platform GEDA 1500 Z/ZP unites two different machines in one: a hoist for materials with a load bearing capacity of 2000 kg and a transport platform for material and persons. In contrast to ordinary material hoists, for which the transport of people is strictly prohibited, the GEDA 1500 Z/ZP may transport 7 people in addition to goods as soon as it has been switched to the operating mode “transport platform“. Just as for all other GEDA twin mast transport platforms, you can choose between a lot of different transport platforms and as many different types of roofs. The load platforms provide enough space for bulky and heavy building materials. This can help to improve logistics on site. In order to prevent people from falling down, hot-dip galvanized landing level safety gates with mechanically locked sliding doors are installed to all loading and unloading points.

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2. This Multiformer MF 500 MAX consists of: English wheeling machine MF 500 + Handformer HF 100 for shrinking For our Handformers, we offer a wide range of tools (tools are not included in the scope of delivery of this machine). Optionally available with a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the tried and tested planishing hammer GL 2 and/or the Handformer HF 100. This Multiformer MF 500 EW consists of: English wheeling machine MF 500 Optionally available with a Handformer HF 100 for shrinking and/or a planishing hammer GL 2 (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

ECKOLD MF 500 - Allrounder-machine with multiple functions to fabricate sheet metal: planishing, wheeling and shrinking The ECKOLD MultiFormer MF 500 combines three machines in one multi-function unit. The MF 500 is able to planish, wheel and shrink sheet metal and is therefore a highly attractive and affordable option for vintage car restorers, technical colleges and artists. All forming tasks can be completed in a single C-frame, using separate modules for planishing, wheeling and shrinking. The MultiFormer MF 500 can also be combined with the Handformer HF 100. This Multiformer MF 500 GL 2 consists of: English wheeling machine MF 500 + planishing hammer GL 2 Optionally available with a Handformer HF 100 for shrinking (not included in this offer). Max. forming capacity Steel 400 N/mm²: 1.5 mm Aluminium 250 N/mm²: 2.0 mm Inox 600 N/mm²: 1.0 mm Order now!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

One of the most significant and functionally important components of working machines is their spindle unit. It operates as guidance and drive of tool respectively work piece. It is very important that its function is fulfilled precisely. As a manufacturer of a wide range of machining spindle units naturally short-term maintenance and repairs belong to our service package. In addition to repair of our own products we are also able to repair spindle units with bearings made by other manufacturers. Examination on receipt / disassembling Quotation Rework / remanufacture Assembly Test run Test certificate

Request for a quote

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quote

STARRAG GMBH

Germany

The Bumotec s191V is the combination of proven Swiss made mechanics and stateoftheart CNC control and drive technology. With the CNC Bumotec s191V mill / turn center, precise and complex components can be produced via 5axis machining. Thanks to its stable mechanical concept and its linear drive technology, accuracies of just a few microns can be achieved. The integration of an individually adaptable automatic workpiece change unit, allows the machine to be used for one off prototypes or to run so called «unmanned shifts» without personnel. Many different configurations are available with three to five axes of machining capacity. The thermal stabilization unit almost eliminates warmup cycles when starting or after machining interruptions. Features Linear driven motors and directdriven rotation axis High speed spindles (maximum 40,000 rpm) Smart combination of turning and 5axis machining High thermal stability Automatic tool changer for 90 HSK40 tools

Request for a quote

WHITE STEEL GMBH

Germany

1,Specification •,CIP Unit •,Storage tanks •,IP56 Control panel •,Piston Homogenizer •,Double jacket mixer Preparation unit •,Pasteurizer machine •,Butter molds melting tank •,Pasteurization Holding tubes •,Swing bend panel •,Lobe pumps PL150 •,End product storage tank with double jacket “ heat and cooling system •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quote

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

The S 1401 is a stationary ultra fine filter system for connection to the control cabinet and for constant processing of technical oils. It runs completely independent with a motor-/pump unit. Especially on machines with continuous dirt- and water contribution it guarantees highest oil purity in the whole system. Integration into the control system of the machine enables setting of flexible processing times. These systems can also be manufactured due to individual installation measures on request. 400 V-asynchronous motor, 0.55 kW, robust construction Stable gear pump, 14 liter/minute Manometer for flow- and element control Robust design, very loadable 24/7 – unattended operation Transfer-circuit Flow regulation for high viscosity oils 1.50 m flow-/return hose Also suitable for high viscosity oils

Request for a quote

TEST GMBH

Germany

For measuring ranges up to 600 Nm Torsion testing machines by TesT are also available as vertical machines, equipped with T-slot table and height-adjustable drive. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

With TesTWinner® TesT has developed a system which enables the user to arrange nearly every imaginable test procedure freely and, most notably, very easy. By stringing together and by parameterizing, a limited number of preset macro instructions permits the designing of complex test procedures without requiring any programming knowledge. TesTWinner® possesses a library with approx. 300 programs acc. to national and international norms as well as customer-specific regulations. TesTWinner® is more than a mere machine control unit and offers furthermore many additional functions such as real-time-calculations and illustrations of derived values e.g. clamping, strain, adhesion factors, etc. Also, the generation of statistics, a report editor, the import of external signals, the communication with CAN / LIN bus systems and much more is possible. The software is compatible to all current Windows operating systems.

Request for a quote

TEST GMBH

Germany

Torsion testing machines by TesT are executed as horizontal machines with torsionally rigid machine bed. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

Positioning system with protection class IP 68 for hygienic applications The PSW 31x/33x-14 positioning systems are intelligent, compact solutions for the automatic adjustment of auxiliary and positioning axes comprising an EC-motor, gear, controller, measuring system and bus interface. The integrated electronic control feature frees up the machine´s central control unit. No external motors, proximity or limit switches are required. The absolute measuring system eliminates the need for time-consuming reference runs. Direct measurement of the position at the output shaft ensures highly accurate positioning. The galvanically separated supply voltages for the control and performance electronics permit the implementation of an emergency shut-off function without interrupting communication with the control module. Address and baud rate switches simplify start-up.

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

Positioning system with protection class IP 68 for damp area applications for wet area applications The PSW 30x/32x-14 positioning systems are intelligent, compact solutions for the automatic adjustment of auxiliary and positioning axes comprising an EC-motor, gear, controller, measuring system and bus interface. The integrated electronic control feature frees up the machine´s central control unit. No external motors, proximity or limit switches are required. The absolute measuring system eliminates the need for time-consuming reference runs. Direct measurement of the position at the output shaft ensures highly accurate positioning. The galvanically separated supply voltages for the control and performance electronics permit the implementation of an emergency shut-off function without interrupting communication with the control module. Address and baud rate switches simplify start-up.

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

Positioning system with protection class IP 65 for damp area applications The PSS 30x/32x-14 positioning systems are intelligent, compact solutions for the automatic adjustment of auxiliary and positioning axes comprising an EC-motor, gear, controller, measuring system and bus interface. The integrated electronic control feature frees up the machine´s central control unit. No external motors, proximity or limit switches are required. The absolute measuring system eliminates the need for time-consuming reference runs. Direct measurement of the position at the output shaft ensures highly accurate positioning. The galvanically separated supply voltages for the control and performance electronics permit the implementation of an emergency shut-off function without interrupting communication with the control module. Address and baud rate switches simplify start-up.

Request for a quote

HALSTRUP-WALCHER GMBH

Germany

Positioning system with protection class IP 65 for hygienic applications The PSS 31x/33x-14 positioning systems are intelligent, compact solutions for the automatic adjustment of auxiliary and positioning axes comprising an EC-motor, gear, controller, measuring system and bus interface. The integrated electronic control feature frees up the machine´s central control unit. No external motors, proximity or limit switches are required. The absolute measuring system eliminates the need for time-consuming reference runs. Direct measurement of the position at the output shaft ensures highly accurate positioning. The galvanically separated supply voltages for the control and performance electronics permit the implementation of an emergency shut-off function without interrupting communication with the control module. Address and baud rate switches simplify start-up.

Request for a quoteResults for

Machining unit - Import exportNumber of results

75 ProductsCountries

Category

- Woodworking - machinery and equipment (25)

- Machine tools, metal machining - parts and accessories (9)

- Servomechanisms (8)

- Plastics - machines and material for industry (3)

- Electric cables (3)

- Forming - steels and metals (3)

- Automation - systems and equipment (2)

- Mechanical engineering - custom work (2)

- Machine tools - metal machining (1)

- Packing and packaging - machinery and equipment (1)

- Bearings, roller (1)

- Food industry - machinery and equipment (1)

- Hoists and elevators, construction (1)

- Lifting - vehicles (1)

- Milling - machine tools (1)

- Oil filters (1)

- Perforation of steels and metals (1)

- Presses, hydraulic (1)

- Tools & Hardware (1)

- Trolleys and trucks (1)