- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- locks for safes

Results for

Locks for safes - Import export

ROLLON GMBH

Germany

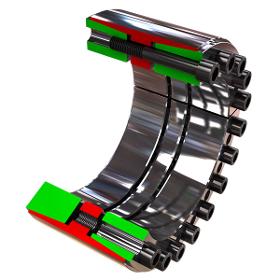

The Hegra Rail family includes various telescopic guide profiles with ball cage capable of handling high loads up to 20 kN per pair, overextensions up to 200% of the length of the guide in closed position and available in different materials such as steel, aluminium or stainless steel AISI 304 and AISI 316. The main features of the Hegra Rail telescopic guides: handling of heavy loads combined with minimal bending profiles with 1, 2 or 3 moving elements for extensions up to 200% available in different materials: steel, aluminium, stainless steel AISI 304 and AISI 316 high rigidity and moment of inertia with thin sections fluid noiseless operation long working life extremely reliable The Hegra Rail family of telescopic guides includes five product categories: partial and full extensions, overextensions, heavy loads and S-sections. Telescopic guides for partial extensions,Telescopic guides for full extensions,Telescopic guides for overextensions,Telescopic guides for heavy loads

Request for a quote

ROLLON GMBH

Germany

High load capacity and reduced deflection telescopic rails with caged balls bearings. The telescopic guides have optimal running properties due to inductively hardened raceways. TELESCOPIC RAIL linear slides exhibit little deflection while under very heavy loads, even when fully extended. Telescopic guides come in eight different series (DS, DSE, DSC, DE, DBN, DMS, ASN, DRT) Torsionally rigid intermediate elements with S-shaped, double-T, or squared sections Over-extending, full or partial telescopic strokes are available In the DMS63 Series the supported load can reach 2,000kg per pair. Extremely low deflection and smoothness of movement even in high load, 24/7 applications Some Series can be locked in the closed position Special versions and strokes available upon request The Telescopic Rail product family includes full or partial extraction telescopic rails, and consists of eight (8) different sizes. The deflection resistant central components are available in the S, double T...

Request for a quote

BARTSCHER GMBH

Germany

Handy barrier post system for extra safety and order – the 1.8 metre tape, 3 integrated tape fasteners and attached safety lock ensure safe, flexible and needs-based use anywhere.

Request for a quote

CROBBER

Germany

"The only bristled drive board. – suitable for all pads on the market – Outstanding colour marking for clear identification as drive board – special inclined position of the filaments for optimal fixture and drive of the pads – when using cro-connect with integrated cro-lock there is a safe hold of the pads when lifting the brush unit Pad operating widths: 12"" - 22"""" Fill type: PP 100 Water hole: with / without"

Request for a quote

CROBBER

Germany

"The classical drive board with high-quality plastic barbed hooks. – suitable for all pads on the market – perfect hold and gentle treatment of the cleaning pad – innovative geometry of the plastic barbed hooks – resistant to chemicals of all common cleaning agents – almost unlimited life through unique plastic formulations – with cro-connect and integrated cro-lock safe hold of the pads when lifting the brush unit Pad operating widths: 12"" - 22"""" Water hole: with / without Including matching cro-connect"

Request for a quote

CRAEMER GMBH

Germany

The CC1 pallet collar is compatible with plastic and wooden pallets. The pallet collar can be used as a single collar and convinces with its easy, foldable handling for modern logistics. In addition, the interlocking rims of the CC1 ensure safe stacking of another pallet. The variable application possibilities enable hassle-free and flexible palletising. Characteristics: Safe and easy locking mechanism Integrated handles Labelling field for adhesive labels Transponder bracket Interlocking 75% volume reduction when folded Increased vehicle fill (double or triple stacking) Options: Rim options RFID transponder

Request for a quote

BERNSTEIN AG

Germany

Mechanically highly stressed components – such as the rotating head – are made of metal. This makes it extremely robust and durable. The plastic housing, on the other hand, is light and functional. A variant with M12 plug connector allows a particularly simple connection to the machine. Another user-friendly feature is the possibility of flexible contact assembly: The contact combination of NC and NO for monitoring the door position and the guard locking can be freely combined at the factory. MANY FEATURES AT A GLANCE • Lightweight yet robust: Hybrid of metal and plastic • Flexible contact assembly • Integrated manual release • Symmetrical design • Five actuating positions • Rotatable head ( 4 × 90° ) • Fail-safe guard locking system • Optional emergency release • Optional escape release • M12 connector as an option

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

The CONEC connector series with bayonet quick locking system allows safe and quick locking even in areas that are difficult to reach and/or not visible. With the "three-point" bayonet locking it is possible to lock the connection by hand with a 90 ° turn. You get a direct tactile and acoustic feedback as soon as the connector is locked. The connectors are designed according to the draft standard IEC CD 61076-2-011/Ed1. In order to meet the mechanical requirements with regard to tightness to dust and liquid media in industrial environments, no additional tools are required for the new M12 bayonet version by CONEC. When locked, the requirements of protection degrees IP65, IP67 and IP69K are met. In addition, the new series is shock and vibration resistant according to the railway requirements IEC 61373:2010, class 1B. The CONEC bayonet locking variant thus offers simplified handling and at the same time secure transmission of signals and data to the user.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

CONEC SnapLock hoods come with a locking system for quick and easy locking. Time-consuming screwing of the hood to the mating connector is no longer required and thus a long lasting connection is made without losable screws. Due to the audible and tangible “click”, even poorly visible device interfaces can be locked quickly and safely. CONEC SnapLock hoods are available in black or metallised plastic material in shell sizes 1-5. The hoods come with one straight cable entry and depending on the number of poles one or two side cable entries. With an upgrade kit, existing interfaces are also compatible with a CONEC SnapLock hood. The CONEC SnapLock system also allows a hood-to-hood connection.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

The CONEC connector series with bayonet quick locking system allows safe and quick locking even in areas that are difficult to reach and/or not visible. With the "three-point" bayonet locking it is possible to lock the connection by hand with a 90 ° turn. You get a direct tactile and acoustic feedback as soon as the connector is locked. The connectors are designed according to the draft standard IEC CD 61076-2-011/Ed1. In order to meet the mechanical requirements with regard to tightness to dust and liquid media in industrial environments, no additional tools are required for the new M12 bayonet version by CONEC. When locked, the requirements of protection degrees IP65, IP67 and IP69K are met. In addition, the new series is shock and vibration resistant according to the railway requirements IEC 61373:2010, class 1B. The CONEC bayonet locking variant thus offers simplified handling and at the same time secure transmission of signals and data to the user.

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of a locking assembly is the safe connection of a shaft to a hub by means of friction. For example, between a shaft and a gear hub. The locking assembly creates a play-free connection by expanding between the shaft and the hub. This type of connection is used mainly for transmitting torque. It is installed by inserting the locking assembly between the components and the subsequent tightening of the screws. By using conical surfaces, the outer diameter increases and the inner diameter reduces. Radial pressure is built up. The clamping forces are provided and controlled by the screws (force-controlled). This allows the direct compensation of the clearance between shaft and hub. The supplied locking devices are ready for installation. To achieve proper operation with a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be clean and slightly oiled. Machine oil must be used as a lubricant. The functional surfaces of the locking...

Request for a quote

KARDEX DEUTSCHLAND GMBH

Germany

Protection from fire or theft can be a very important part of good document management. But it is not just fire: A whole range of disasters including burglary, flood, electrical failure, vandalism and terrorism put thousands of companies out of business each year. The Kardex Remstar Disaster Protection range has been specially designed to offer point of use protection, not just from fire but burglars, vandalism and floods too. Document Safes: Range in performance from 30 minutes to two hours fire protection Filing cabinets, free standing or small units Fully customisable with internal fitments to meet all requirements Available with key lock or electronic lock options Data Media Safes: Range in performance from one to two hours fire protection Available in a range of sizes to allow protection for varying amounts of media. Fully customisable with internal fitments to meet all requirements

SEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description NC-Rotary and Swivel unit SKS-NC5 - duplex worm dirve, i=120 - safe transport load: 700 kg - table plate: Ø 630 mm ( T-groove 1x22H7, 6x22H12) - maximum table speed: 6.25 RPM at motot n=3,000 RPM - safe axial load: 35,000 N - safe radial load: 35,000 N NC-Swivel axis SKV-NC5 - duplex worm drive, i=90 - maximum table speed 4.7 RPM at motor n=3,000 RPM Counter bearing SKH-NC5 - with preloaded Aixial-Radial bearing - with hydr. table locking p=63 bars - safe tangential stress: 4,200 Nm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description Single-axis NC milling head prepared for motor spindle KF/M2/90-NC5 P=68 kW, n=10,000 RPM C-axis (NC-clevis-swivel axis): - working range: ± 90° Accuracy: - dividing accuracy: in angular seconds ± 6 - repeatability: in angular seconds ± 1 Load data: - safe mass moment of inertia issuing from transportation load: 40 kgm² - safe tangential stress (at 63 bar lock pressure): 4,200 Nm - safe tilting moment: 6,300 Nm - safe torque to be transmitted by worm gear: 2,500 Nm

Request for a quoteResults for

Locks for safes - Import exportNumber of results

38 ProductsCountries

Company type