- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- liquid painting

Results for

Liquid painting - Import export

LUTZ PUMPEN GMBH

Germany

Eccentric screw pump tube HD-E Industryfor oils, paints and disposal liquids is available in the food version (Pure) The HD-E Eccentric screw pump in the industrial version transfers the advantages of the Drum pump low-viscosity media quite simply to the medium-viscosity range. The positive displacement pump has an easily detachable outer tube, a bearing head with mechanical seal and a free-running shaft with an eccentric screw as the pumping element - all easy to dismantle and clean. The Pump tube can be suitably combined with our single-phase motor. This ensures the draining of liquids and thus saves important resources. * also available in special immersion depths * Pump tube equipped with Lutz original hand wheel * Media examples: Oils, waste oils, disposal liquids, paints. * Smooth running * Uniform volume flow * Gentle, low-pulsation product conveying * Low wear * Easily detachable outer tube

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as Paints, lacquers, acids, alkalis, mineral oils, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently. * Optionally in explosion-proof design * Measurement according to the oval wheel principle * High measuring accuracy due to overtravel correction * Low pressure losses in the system * Touch screen display with self-explanatory, multilingual user interface * Relay module for quantity preselection can be retrofitted at any time * Approved according to ATEX Directive 2014/34/EU, category 2

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flow meter with touchscreen display and backlighting impresses with its simple, needs-based display and operability, multilingual interface and compact design. Thanks to the rotating oval wheel meters and the magnets placed on the measuring wheels, it enables precise measurement of the volume flow and measures non-flammable liquids such as paints, varnishes, acids, solvents, alkalis, mineral oils, hydrocarbons and highly flammable liquids precisely, quickly and, above all, efficiently. * Optionally available in an explosion-proof version Features & benefits * Measurement according to the oval gear principle * High measuring accuracy due to overrun correction * Low pressure loss in the system * Touchscreen display with self-explanatory, multilingual user interface * Relay module for volume preselection can be retrofitted at any time * Approved in accordance with ATEX Directive 2014/34/EU, Category 2

Request for a quote

LUTZ PUMPEN GMBH

Germany

The first flow meter with touchscreen display and backlighting impresses with its needs-based display and operability, multilingual interface and compact design. Thanks to the rotating oval wheel meters and the magnets placed on the measuring wheels, it enables precise measurement of the volume flow and measures non-flammable liquids such as paints, varnishes, acids, solvents, alkalis, mineral oils, hydrocarbons and highly flammable liquids precisely, quickly and, above all, efficiently. * Optionally available in explosion-proof design Features & benefits * Measurement according to the oval gear principle * High measuring accuracy due to overrun correction * Low pressure losses in the system * Touchscreen display with self-explanatory, multilingual user interface * Relay module for volume preselection can be retrofitted at any time * Approved in accordance with ATEX Directive 2014/34/EU, Category 2

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology considers your individual requirements and builds customised plants and systems for the paint industry and the varnish industry. Our plants and systems for dosing liquids and solids in the paint and varnish industry offer high dosing accuracy and perfect reproducibility. We meet the high demands of our customers through the use of high-quality materials and precise workmanship. Application of plants and systems for the paint industry and the varnish industry: Storage, mixing, dosing and application of paints and varnishes Special dosing valves and dosing pumps for paints and varnishes

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as alkalis, paints, lacquers, mineral oils, solvents, hydrocarbons and solvents as well as highly flammable liquids precisely, quickly and above all efficiently. * Optionally in explosion-proof design * Measurement according to the oval wheel principle * High measuring accuracy due to overtravel correction * Low pressure losses in the system * Touch screen display with self-explanatory, multilingual user interface * Relay module for quantity preselection can be retrofitted at any time * Approved according to ATEX Directive 2014/34/EU, category 2

Request for a quote

LUTZ PUMPEN GMBH

Germany

The flowmeter with touchscreen display and backlighting convinces with its simple, demand-oriented display and operability, the multilingual interface and the compact design. Thanks to the rotating Oval gear meter and the magnets placed on the measuring wheels, it enables accurate measurement of the volume flow and at the same time measures non-flammable liquids such as Paints, lacquers, mineral oils, acids, alkalis, mineral oils and solvents as well as highly flammable liquids precisely, quickly and above all efficiently. * Optionally in explosion-proof design * Measurement according to the oval wheel principle * High measuring accuracy due to overtravel correction * Low pressure losses in the system * Touch screen display with self-explanatory, multilingual user interface * Relay module for quantity preselection can be retrofitted at any time * Approved according to ATEX Directive 2014/34/EU, category 2

Request for a quote

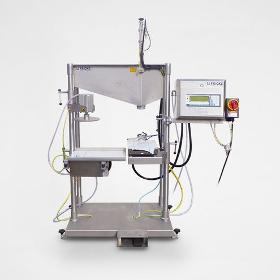

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For filling open containers just above the fill level, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above level filling just above the fill level with a ride-ci n valve ■ thread-cutting, non-dripping filling valve ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ filling, sealing and palletizing by one person ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Semi-automatic filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. The filling station has the following advantages: ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 12 enables complex control tasks, MES/ERP connections and remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line at any time, including automatic container conveying, capping and labelling. It is suitable for viscous to pasty liquids such as paints and varnishes and offers automatic container transport options as well as an electronic scale. The station supports coarse/fine over-level filling and can be connected directly to storage tanks via inclines or pumps. The system offers you: ■ a calibratable oversize filling system ■ quick cleaning of the valve (the area in contact with the product consists of 3 parts) ■ quick changeover to other container dimensions and changing products ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 42 enables complex control tasks and MES/ERP connections as well as remote maintenance. Its modular design allows it to be expanded into a fully automatic filling line with container conveying, capping and labelling. Suitable for viscous to pasty liquids such as paints, it features an electronic scale and fills open containers just above the filling level. The product is fed from storage tanks by gravity or pumps. ■ a calibratable over-level filling unit with travelling valve just above the filling level ■ Thread-cutting, non-drip filling valve ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ The ideal solution for small and medium-sized filling orders ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect energy (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or inks. For filling open containers, e.g. cans, buckets, canisters. Above level filling coarse/fine. Product feed from intermediate container positioned above the scale with bottom discharge valve using natural drop. The System offers you: ■ calibratable above level filling ■ Thread-cutting, non-dripping filling valve ■ fast cleaning of the container (container and valve are cleaned in approx. 5 min using 1 l of solvent) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 10 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers, such canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. Above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibrated above level filling of several containers on one pallet ■ thread-cutting, non-dripping filling valve ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ Handling of empty containers (lifting heavy loads (filled containers)) not applicable

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A filling station with electronic scale for the filling of viscous to pasty liquids e.g. paints. varnishes or dispersions, adhesives, bitumen. For the filling of open containers (min. Ø 150mm opening) just above fill level, e.g. canisters, open lidded drums or IBCs (Intermediate Bulk Container), directly on the pallet. above level filling coarse/fine. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. The System offers you: ■ calibratable above tevel filling just above the fill level with a ride-on valve of several containers on one pallet ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ simple operation by one person ■ handling of empty containers (lifting heavy loads (filled containers)) not applicable ■ automatic height adjustment and automatic change of position

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 50 is a semi-automatic filling machine with over and under level valves for the precise filling of viscous to pasty liquids such as paints, varnishes or adhesives. It is suitable for over-level filling into open containers such as cans and buckets as well as for under-level filling into bunghole containers, e.g. canisters, for foaming, gassing or statically charging liquids. ■ a calibratable over-level filling system ■ Thread-cutting, non-drip filling valve ■ an almost foam-free, calibratable under-level filling system ■ quick cleaning of the valve ■ Quick changeover to other container dimensions and changing products ■ the ideal solution for small and medium-sized filling orders ■ Simple operation by one person ■ Filling capacities of up to 10 containers per minute ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

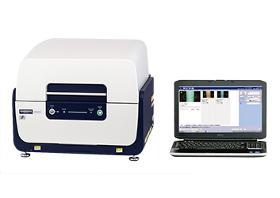

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

With this high-end spectrometer the advantages of a fast and precise 50mm2 SDD, a flexible and robust X-Ray excitation and a motorized XYZ-stage can be used to analyse a wide range of samples in fast, reliable and precise measurements. This includes for example (but not restricted to): - solids (like metal alloys, minerals, jewellery, electronic parts [PCB],…) - powders (minerals, ceramics, paint, soil,… ) in a corresponding holder - liquids (oils, solutions, paint, …) in a corresponding holder A Dual CCD camera system with wide view and high-magnification view enables a precise positioning of the sample easily from a big area to investigate exactly to region of interest you want to analyse. With the help of the optical system an easy navigation over the sample is possible and a laser-based auto-focus system ensures correct measurement position. Furthermore a second laser-system prevents collisions. The easy identification of areas containing targeted elements is possible by combi

Request for a quote

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

The use of XRF techniques enables a non-destructive analysis of nearly all kind of samples with almost no pre-processing. Already this basic spectrometer configuration allows you to analyse: - solids (like metal alloys, minerals, jewellery, electronic parts [PCB],…) - powders (minerals, ceramics, paint, soil,… ) in a corresponding holder - liquids (oils, solutions, paint, …) in a corresponding holder with respect to the latest restricted materials guidelines (like RoHS, WEEE, etc.) but also in a more general way to estimate the composition in an element range from Al (13) to U (92). A CCD camera is used to position the sample that only the area of interest is measured – with the use of suitable collimators a minimum spot size of 1mm can be realized. To enhance the measurement speed and analytical performance (energy resolution) the EA1000VX is equipped with a state-of-the-art 50mm2 SDD detector (no liquid Nitrogen needed anymore). This hardware allows you to analyse film thickness

Request for a quoteResults for

Liquid painting - Import exportNumber of results

23 ProductsCountries

Company type