- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- liquid nitrogen

Results for

Liquid nitrogen - Import export

DRESSLER GROUP

Germany

DG Grinding processes with simultaneous cooling of the raw material to temperatures far below ambient temperature (e.g. minus 30°C); usually done with the help of liquid nitrogen, which has a temperature of around minus 196°C.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® explosionproof flow heaters are used for heating up flowing gases and liquids in hazardous areas. The devices consist of explosionproof flanged immersion heaters, which are installed in corresponding pipe or pressure vessel. Our products realize individual solutions for complicated technical process. Different heating systems for heating up liquids, nitrogen or other gases activate exact determinded processes in chemical factories. In close discussion with our customers problems will be defined and changed in technical optimale solutions. Our QualityManagementSystem ensures the high quality level of our customers. Further information about our CSN® Exflow heater

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

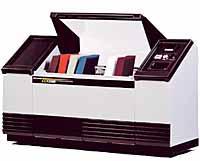

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

FILLPACK GMBH & CO. KG

Germany

Glass sealing machine for bottles with N2 gassing Machine performance: 40 cycles/min. 80 glasses/min. Special features: Dosing of liquid nitrogen Film applicator station Sealing station

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

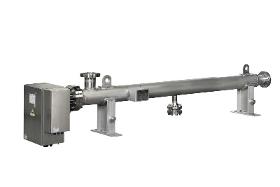

Cryogenic Mill The solution for fine grinding temperature-sensitive products. Our cryogenic grinding plants enable fine grinding of lubricating and temperature-sensitive products. This not only results in a technically perfect grinding but in addition thermal damage of the ground material and resulting grinding losses are prevented by the cryogenic grinding. All plants are designed with swivel screw coolers and liquid nitrogen cooling, appropriate dosing devices, separators as well as bunkers as closed plants. Technical data Target fineness: 10-2,000 µm Plant types: Pin mills, cross beater mills Product-contacting parts: Stainless steel Cooling: By liquid nitrogen Delivery in: Bagged goods, Big Bags, oktabins, drums Feeding: Via feeding stations, metering screws and vertebral screw coolers Filling into: Bags, drums, Big Bags, cardboard boxes and special containers Areas of application Fine grinding of resins Fine grinding of foodstuffs Fine grinding of seeds Fine grindi

Request for a quote

HITACHI HIGH-TECHNOLOGIES EUROPE GMBH

Germany

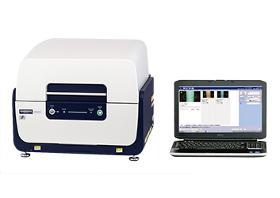

The use of XRF techniques enables a non-destructive analysis of nearly all kind of samples with almost no pre-processing. Already this basic spectrometer configuration allows you to analyse: - solids (like metal alloys, minerals, jewellery, electronic parts [PCB],…) - powders (minerals, ceramics, paint, soil,… ) in a corresponding holder - liquids (oils, solutions, paint, …) in a corresponding holder with respect to the latest restricted materials guidelines (like RoHS, WEEE, etc.) but also in a more general way to estimate the composition in an element range from Al (13) to U (92). A CCD camera is used to position the sample that only the area of interest is measured – with the use of suitable collimators a minimum spot size of 1mm can be realized. To enhance the measurement speed and analytical performance (energy resolution) the EA1000VX is equipped with a state-of-the-art 50mm2 SDD detector (no liquid Nitrogen needed anymore). This hardware allows you to analyse film thickness

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Liquid nitrogen - Import exportNumber of results

6 ProductsCountries

Company type