- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linings

Results for

Linings - Import export

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Overhead and underground conductors in various designs and constructions for the construction of new lines, the repair of existing transmission grids, the connection of transformer substations, solar and wind power plants. Furthermore, the upgrading of existing lines with high-temperature conductors to increase transmission capacity.

Request for a quote

RONIX GMBH

Germany

For the uninitiated, let us explain what laser level is. The laser level makes perfect and efficient use of laser beam technology to project a laser-level line on the horizontal or vertical plane. This line helps you get an idea of vertical and horizontal alignment. It was originally introduced for use on the job site. The early predecessors of the modern laser level were bulky and expensive tools, too expensive for everyday use. Modern laser levels are less expensive and easier to transport. It will not be wrong to say that it has revolutionized the entire construction and other related projects. The results obtained after using a construction laser level are much more accurate than before and the whole process has been shortened and more efficient. A true technological innovation, the Ronix RH-9500G offers incredible performance to professionals and individuals alike.

Request for a quote

ROLLON GMBH

Germany

Linear and curved guides with ball and roller bearings, with hardened raceways, high load capacities, self-alignment and capable of working in dirty environments.

Request for a quote

ROLLON GMBH

Germany

Linear actuators with different guide configurations and drives, available with belt, screw or rack and pinion drives according to different needs in terms of precision and speed. Guides with bearings or ball recirculating systems for different load capacities and critical environments.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The innovative LAWECO CHAIN-LINE lifting platform technology unites all advantages of belts and spindles. Mechanically driven by a push-chain, this technology achieves maximum performances without the use of hydraulic oil. Due to a particularly harmonious motion sequence and the excellent load change behaviour in each lift position, the CHAIN-LINE is the preferred solution for designers who place an extremely high value on efficiency and precision for their area of responsibility. Unsurpassed precision LAWECO push-chain lifting platforms convince with a load behaviour and maximum positioning precision which were almost unachievable in the past. Unrestricted availability Almost maintenance free, the robust and low failure construction permits fast component replacement. Safety for the environment and employees The intelligent design does without hydraulic oil. Optional contact rails and bellows increase safety.

Request for a quote

GSW SCHWABE AG

Germany

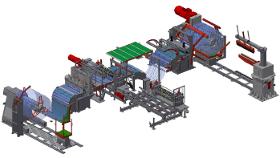

With Conventional Feed Lines, the focus lies on speed and material surface. That’s why Conventional Feed Lines are equipped with a Coil Reel for pull-off, a Straightener with variable frequency drive a coil loop and a Servo Roll Feed: the loop uncouples the more inert straightening process from the highly dynamic indexing process and thus allows for high line speeds and preservation of the material surface. Since productivity and capacity demands can vary significantly, we have created different control concepts: while small Feed Lines work with a simple pneumatic drag brake at the Coil Reel and an ultrasonic sensor to control the Straightener speed, the large Feed Lines get fully synchronized controls with motor-limited Coil Reels and a smart loop, creating a steady average speed of the whole line. This allows smooth pull-off of high coil weights while the loop remains very calm – in addition, the Servo Roll Feed can work with full dynamics, even at long indexing progressions.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Pipe lining made of cast polyurethane (75 Shore A). The lining is held from the outside via two flanges. Due to the extremely good abrasion resistance you have proven our linings!

Request for a quote

HOCHRAINER GMBH

Germany

Assembly line for micro gas generator (belt tensioner) Workpiece carrier transfer system (above/below level) with multiple automation stations

Request for a quote

GSW SCHWABE AG

Germany

If you need two Coil Reels to hold one coil, you need a Heavy-Duty Coil Feed Line above all. One that is designed extremely robust and knows to subdue even materials of highest bounce and largest cross-sections.To ensure this, we have taken no heed to cost savings but went by the maximum principle: 2 Coil Reels with high-performance arbors retain the coils from left and right. 2 x 2 hydraulic arms secure them from top and bottom – each with eight tons pressure force, each with hydraulically driven snubber roll. The loading is done with one central lifting gear built into a super-duty running frame for the V-nest. Hydraulic manipulators with pivoting and bending function support the threading of the material. On the receiving end, a Pre-Straightener with 200mm work rolls takes over, after hydraulic edge guides have ensured central entry. Now, if someone asks us our definition of “heavy-duty”: We find 36.000 kilogram coil weight and 2.

Request for a quote

GSW SCHWABE AG

Germany

A perfect combination of space savings and dynamics: the GSW Compact Feed Lines Our Compact Feed Lines are an ideal answer to the challenge of a constraint floor and necessity to process thick materials. Marrying the processes of leveling and indexing into one Feeder-Straightener machine allows for a complete Feed Line with only two individual machines and thus greatly reduces the necessary length. Additionally, the decoupling of the coil mass from the indexing process – achieved through a short loop between Coil Reel and Feeder-Straightener – enables dynamic feeding despite the compact footprint. And, if cross-sections are especially big, the loop can be spared completely, creating yet more space. One more advantage, virtually a by-product out of their very nature, is the quicker set-up of our Compact Feed Lines. This elevates them to not only space- but also time-savers!

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

MICRO-EPSILON

Germany

The LVP-25-Z20 and LDR-14-Z20 sensors are used for monitoring the clamping position in machine tools. These inductive sensors are integrated in the release device and directly measure the clamping stroke of the drawbar onto which the target ring is glued. Due to their extremely compact design, these sensors are used for different types of tools while providing high-precision and continuous monitoring. No adjustment is necessary when changing the tool.

Request for a quote

SCHOLL APPARATEBAU GMBH & CO. KG

Germany

Insulated cooling basin and neon-lighting, without cooling aggregate, for crushed-ice.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

A clamping ring machine is a system for the automatic production of clamping rings. Schmale Maschinenbau Gmbh is one of the leading manufacturers of clamping ring machines in Europe. On our clamping ring machines, the strip material is profiled, bent and cut. Automatically closures are supplied and welded. The finished clamping ring is calibrated and stored. Via a servo-electric transfer, all processing stations are connected to each other and operated simultaneously. Thus, cycle rates of up to 28 clamping rings per minute can be realized.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

Applications Pipes for the construction of pipelines for water, liquid hydrocarbons, natural gas and for the construstion of chemical and industrial plants, refineries etc. Norms Line pipes are according to the following norms: API 5L (ISO3183) (seamless and welded pipes) ASTM A53 / ASME SA53 (seamless and welded pipes) Manufacturing methods Seamless pipes, hot rolled or cold finished with following heat treatment: ERW pipes up to dia 24" and SAW pipes for the other sizes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LALK GMBH &CO. KG

Germany

It creates a horizontal and vertical laser line on the wall or floor, thereby creating an exact 90° angle. The first row of tiles on the floor or wall can thus be laid very precisely. With the line laser you create you create a perfect grout pattern !

Request for a quote

FRIEDR. FREEK GMBH

Germany

Freek pump and gas line heaters for trace heating are designed to regulate temperatures in order to prevent freezing or condensation in the line. As with all our heaters, these can be designed and produced to your bespoke specifications. A most frequent application for gas & pump line heaters the semi-conductor process in which gases such as Tetraethyl Orthosilicate (TEOS), Boron Trichloride (BCl3), Aluminium Chloride (AlCl3), Chlorine Triuoride (ClF3) and Dichlorosilane (DCS) condense at low temperatures. Should this occur, it could result in wafer defect. Gas and pump line heaters consistently heat the lines and provide a simple heating solution and prevent condensation build up. The optimum line temperature will vary depending on the process.

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

single inlet line aluminium housing silicon carbide seal dry running (7600T) PRESSURE MAXIMUM 100,0 bar coolant TEMPERATURE MAXIMUM 90 °C coolant SPEED MAXIMUM 24000 1/min SIZEDN 8 (1/4") DN 10 (3/8")

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We manufacture gears, gear rings and toothed shafts for various applications in industry with a focus on mechanical engineering and heavy machinery. Our customers come from a wide range of industries: railway, wind power, marine, industrial gearboxes, oil and gas extraction, crane construction or construction machinery as well as special machines. We also supply the retrofit industry and manufacture the parts in small series or individual production. Depending on the dimension a quality of 4 can often be achieved. We examine the possibilities without obligation and without charge. Our customers include renowned and well-known companies. References to your industry on request. We manufacture according to customer drawings and have our own hardening plant. This saves time and costs during production. Cooperation exists for gas nitration and single-tooth induction hardening with experts in their field. ZWP supports you in the overhaul of plants and machines (Retrofit).

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The CLMIA.LiNE D KNR ensures ideal ripening conditions for your products. Besides the adjustment of the room's temperature and moisture exactly to the required level, the system has many more advantages For example its intelligent fancontrol, preventing the unintended growth of spores! Constant conditions for reproducible quality Highquality design of aggregate and piping Lowmaintenance system Intelligent fancontrol to prevent unintended sporegrowth

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

camera based end-of-line inspection machine for aerosol cans

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Compressed air blade To monitor the progress of certain processes, there is no alternative but to take frequent samples at the machine itself. This is normally possible only while the product is either moving slowly or stopped, and often results in complicated work-arounds to enable continual production (continuously running winders, etc.). The Samplecut FSC is the solution to the problem. The tried and tested sample cutter Samplecut FSC takes samples from fast running product.

Request for a quote

BIZERBA SE & CO. KG

Germany

Optimizes package handling in material flow systems By channeling up to 6 product lanes into a single line the LCE allows controlled product feeding from the packaging machine to the price labeler. Due to specially formed and Teflon-coated alignment rails the converger belt proves its effectiveness especially for flat packages. It can be infinitely adjusted from 10 - 80 m/minute and individually set for each PLU.

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Our power supply lines and conductors are extremely rugged systems for supplying power and control signals to mobile equipment. They feature high transmission reliability and ease of installation and maintenance. And they are equally suitable for applications on cranes and other rail-mounted equipment. In harsh outdoor operating conditions and in dusty working environments. Depending on requirements, our power supply lines and conductors can be supplied in various designs with different numbers of poles.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Special feed line for brake fluid. The supply line connects the brake fluid reservoir and the brake cylinder with one another.

Request for a quoteResults for

Linings - Import exportNumber of results

160 ProductsCountries

- Germany (160)

- Berlin and region (1)

- Bonn, Düsseldorf and North Rhine and Westphalia (42)

- Frankfurt am Main and Hesse (5)

- Hamburg and region (3)

- Hannover and Lower Saxony (10)

- Kiel and Schleswig-Holstein (52)

- Leipzig and Saxony (3)

- Mainz and Rheinland-Pfalz (4)

- Munich, Nuremberg and Bavaria (7)

- Potsdam and Brandenburg (11)

- Stuttgart, Freiburg and Baden-Wurtemberg (19)

- Weimar and Thuringia (3)

Company type

Category

- Compressors (50)

- Wood veneer - machinery and equipment (10)

- Food industry - machinery and equipment (9)

- Metal straightening machines (6)

- Driveshafts and micro-motors - electric (5)

- Automation - systems and equipment (4)

- Spare parts for diesel engines (3)

- Valves for pneumatic equipment (3)

- Food Industry - Machines & Equipment (2)

- Wires and cables, steel (2)

- Measurement - Equipment & Instruments (2)

- Hoses, pipes and tubes - plastic (2)

- Sensors (2)

- Construction - Machines & Equipment (2)

- Conveyor systems (2)

- Rolling mills - machinery and installations (2)

- Coil winders (2)

- Flame retardant construction materials (2)

- Forming - steels and metals (2)

- Gears (2)