- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lining materials

Results for

Lining materials - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

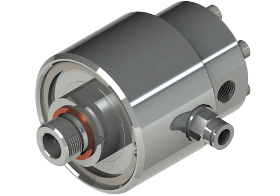

single inlet/outlet line rotor + housing, material stainless steel tungsten carbide/tungsten carbide seal 160,0 bar hydraulic oil water TEMPERATURE MAXIMUM 90 °C hydraulic oil water SPEED MAXIMUM 1500 1/min DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") SIZEDN 8 (1/4") DN 10 (3/8") DN 15 (1/2")

Request for a quote

INFICON GMBH

Germany

Sustainable solution for process measurement, control and data log Compatible to the wide range of INFICON active gauges, the new VGC50x series of active gauge controllers are able to monitor and data log the entire pressure range from 10⁻¹⁰ to 1500 mbar (10⁻¹⁰ to 1125 Torr) and the set point status. The new VGC50x Active Gauge Controller series is the advanced successor of the discontinued VGC40x series which was the 1:1 compatible product Leybold`s Center-Controller line Material-No Typ 230 002 Center ONE 235 002 Center ONE (USA) 230 004 Center TWO 235 004 Center TWO (USA) 230 003 Center THREE 235 003 Center THREE (USA) As the direct successor for these series the new and advanced VGC50x series is able to accept all INFICON Active Gauges Successor product for VGC40x Controller series 1×10 -3×F.S. …1×F.S. 1×10 -3×F.S. …1×F.S. 1×10 -3×F.S. …1×F.S. 5×10 -4…1500 5×10 -4…1500 5×10 -4…1500 5×10 -10…1500 5×10 -10…1500 5×10 -10…1500 mbar, Torr, Pa, hPa, Micron, V mbar, Torr, Pa,...

Request for a quote

MICRO-EPSILON

Germany

thicknessGAUGE sensor systems are used to measure the thickness of strip materials in-line. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces. The systems uses two confocal distance sensors which detect the strip thickness with high precision. The sensors are precisely aligned to each other and factory-calibrated. By means of a linear axis, the thicknessGAUGE sensor systems can be moved to measure the thickness across the entire strip width. Their extremely compact design enables integration into confined spaces.

Request for a quote

STRONG MAGNETS GMBH

Germany

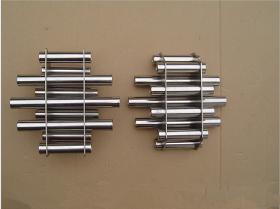

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EISELE GMBH

Germany

- Operating voltage: 630 V AC/DC- Up to 12 A per pin - Operating current per contact max. 12 A - 4-pole - S-coded - Temperatur (fixed line): -25 bis +80°C - Temperatur (moving line): -20 bis +80°C - Material: PUR - Very compact connection for cables with wires up to 2.5 mm² - Reverse polarity protected, shockproof and vibration-proof - Made of high-quality plastic - Molded wires

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our corrugated tubes and smooth tubes with connecting elements are made to customers specifications for use in low pressure duct systems. This guarantees a reliable connection and an easy and time-saving assembly and disassembly. Our product line includes a wide range of nominal sizes and line of matched accessories. Available materials/maximum operating temperature: PP/PA 110°C PA6 120°C PA12 120°C Application: Automotive, agricultural machinery and construction engines; in applications that require a small bend radius and/or dynamic stress environments, ventilation systems, connecting lines between various components for vacuum conveying systems

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

To achieve perfect induction heating processes depends on generators providing precisely the right amount of energy. With its CUSTOM LINE LF generators, eldec provides just the right solution for the low frequency range (2 to 8 kHz). Induction heating with tough generators “Customized” is the key word when it comes to delivering a perfect production solution in mechanical and systems engineering. This is particularly true for induction heating. The process needs to be configured accurately to produce the desired effect in the material. CUSTOM LINE generators by eldec are the ideal solution for delivering precisely the right amount of power and energy. The LF series (power: 50 to 500 kW, frequency: 2 to 8 kHz) is designed for lower frequencies.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards are trimmed, cleaned, checked and (if necessary) cooled in the nishing line. Features, function Any excess material caused by the decorative paper being larger than the carrier board is removed from edges on the nished boards in the edgetrimming unit. Rotating brushes then remove any residues that are clinging to the surface. A member of sta will visually assess the quality of the coated board on both sides at the inspection station. The boa station so that it can be inspected from the bottom. The board is then placed in the stack appropriate for its quality Advantages The modular design allows basic modules and optional modules to

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

These machines are capable of executing complex lapping routines while producing precise and repeatable results. These units, available for maximum component diameters of 51mm on the DL175, 114mm on the DL370, up to 170mm on the DL500, can lap a wide range of materials to very tight specifications. Excellent results have been obtained in the processing of a wide range of materials and components including glass, ceramics, crystals and ferrous materials. The Lapmaster line of Dual-Lap machines are based upon a two-way & three way planetary concept designed to yield very precise and repeatable results. Only the Inner and Outer Gears rotate allowing the carriers to move around the surface of the plates, whilst the top and bottom plate stay stationary. The larger DL500 and DL770 use a 3-way system, where the top plate, bottom plate and sun gear rotate.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The microCut model was specifically designed to meet the requirements of profile and creep-feed grinding applications. The modular column design offers a small footprint which can be easily configured into economical production cells frequently used in the turbine manufacturing industry. This machine is available in compact standard sizes but special designs with spindle power up to 52 kW are also available. The integration into production lines is achieved through automatic material handling and tool changers. A common solution to reduce non-productive time is to equip the microCut with an index table to allow loading and unloading during the machining cycle. For high-precision applications, dressing of the grinding wheel can be done on the table with a diamond roll dressing unit or via interpolation of feed and cross axes. For production grinding the overhead diamond roll dressing unit is used for CDCF or intermitten dressing.

Request for a quoteResults for

Lining materials - Import exportNumber of results

12 ProductsCountries

Company type

Category