- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linear drives

Results for

Linear drives - Import export

ROLLON GMBH

Germany

The SMART SYSTEM linear actuators feature a self-sustaining anodized aluminum frame and steel re-enforced driving belt. This is a series of highly cost effective linear units, featuring high performance combined with a carefully planned simple construction. High load capacity,High speeds and accelerations, High admissible tipping moments, Low friction ,Low noise The SMART SYSTEM series consists of 3 distinct products with different features: E-SMART, R-SMART, S-SMART. SMART SYSTEM – E-SMART .

Request for a quote

ROLLON GMBH

Germany

The PLUS SYSTEM series of linear actuators consists of highly protected linear units featuring a self-sustaining anodized aluminum structure and a steel re-enforced driving belt. This is a line of exceptionally sturdy and high performance actuators in terms of load, moment control, speed and acceleration. High load capacity,High speed,Low wear and tear,Low friction,Low maintenance.Corrosion resistant version All Plus System series of linear actuators are available with stainless steel elements, for applications in harsh environments and/or subject to frequent washes. The Plus System linear units are made by using extruded anodized Anricorodal 6060 and 6082 aluminum, which houses bearings, linear rails, nuts and bolts and components made of low carbon SS AISI 303 and 404C steel, preventing or delaying corrosion caused by humidity experienced in the environments where the linear units are used.The PLUS SYSTEM series consists of 3 distinct products with different features: ELM,Robot,SC.

Request for a quote

ROLLON GMBH

Germany

Modline linear modules are toothed belt or ball screw driven systems with high accuracy, speeds and load performances. Our experience in the fields of the automotive plants, painting, plate working, manufacturing machines and palletization systems has allowed us to widen our product range with the most advanced technical solutions. Our products stand out for their: high quality and competitive performances; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; no play transmissions achieved by high torque couplings; beams with transversal stiffening ribs and preset for threads on profile ends; accurate scaling and consequent reduced maintenance; fast and accurate belt or without play screw drives; the most complete range of accessories. The Modline linear module strong points are: toothed belt or ball screw driven linear modules; rolling on trapezoidal or recirculating ball guides; payloads from 3 to 2000 Kg; up to...

Request for a quote

ROLLON GMBH

Germany

Linear units with a belt drive specifically dedicated to the use along the Z axis. The Modline Z family includes axes with pneumatic compensation of the load. The section integrates the pneumatic cylinder and encloses the passage of cables. It requires smaller motors, offering increased performances with savings in cost and energy. Our products stand out for their: high quality and competitive performances no play transmissions achieved by high torque couplings beams with transversal stiffening ribs and preset for threads on profile ends accurate scaling with reduced maintenance the most complete range of accessories

Request for a quote

IGUS® GMBH

Germany

The drive technology online configurator gives you the right drive technology system after you enter your requirements. You also have the option of requesting or ordering motors and other accessories, such as the motor control system. - Fast and easy configuration - Optional accessories - Detailed parts list - Fast delivery

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Linear units / linear guides Linear units are used in almost every single area of automation and machine engineering. From simple adjustments that may be seldom required, right up to highly complex, highly precise and highly dynamic multi-axis systems. Every task is different. And every task requires a technically accomplished, cost-effective solution. RK linear units – variety offers the ideal solution The wide range of RK linear units is the result of the variety of customer applications. What used to be referred to as 'special applications' have now become readily available, attractively priced standard modules. It is therefore likely that the ideal RK linear unit for your particular application already exists.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Rodless linear drives allow stroke lengths of up to 6000 mm with a reduced overall length. Stable guidance and durable sealing system even at high speeds and temperatures.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The compact, guided cylinder CC is a linear drive with a lot of power and minimal dimensions. Generously dimensioned guide rods on plain bearings or ball bearings open up a wide range of application options in variable positioning with and without sensor queries.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The compact, guided cylinder CC is a linear drive with a lot of power and minimal dimensions. Generously dimensioned guide rods on plain bearings or ball bearings open up a wide range of application options in variable positioning with and without sensor queries.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. The 3D automatic optical inspection of SMD components combines 2D and 3D inspection at maximum speed. Some of our machines allow an inspection in 360 ° steps. Depending on the machine, excellent dynamic properties and the highest positioning speed can be achieved on the basis of linear drives.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of rolling and friction bearings, joints, linear drives, guides For the lubrication of fittings, seals, moulded parts and elements of elastic rubber materials in the hot- and cold-water segment Advantages and benefits NSF H1 registered Can be used universally due to good high-temperature properties, long-term lubricating effect and good adhesive strength on metal surfaces Resistant to hot and cold water, water vapour, watery-alkaline and acidic disinfectants and cleaning agents High resistance to oxidation and ageing

Request for a quote

SIKO GMBH

Germany

Magnetic motor feedback systems are proving themselves in numerous applications in linear drive technology, handling systems, circuit board assembly, robotics and in a wide range of automation solutions in the context of Industry 4.0. In all of these areas, the speed and/or position of a drive must be communicated to a main controller in real time. The ultra compact LEC100 and LEC200 sensor duo has been developed by SIKO for these requirements. Repeat accuracy max. ±1 μm. max. resolution 0.2 µm (LD output circuit). Reading distance ≤0.2 mm. Works with MB100/1 magnetic tape. Signal period 1000 μm. Output circuit sin/cos or LD. Function and status display LEDs.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of rolling and friction bearings, joints, linear drives and chains Lubrication of fittings, seals, moulded parts and elements of elastic rubber materials in the hot- and cold-water segment Lubrication of fittings or machines in dairies, breweries, bakeries, slaughterhouses, etc. Advantages and benefits NSF H1 registered Reduces wear Excellent resistance to oxidation and ageing Resistant to hot and cold water, water vapour, watery-alkaline and acidic disinfectants and cleaning agents

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

The BH25 is a high resolution exposed linear encoder with interferometric measurement signal generation. The BH25 scale has a graduation period of 1µm. The interferometric laser scale principle generates a sinusoidal measurement signal with a signal period of 250nm in the read head. The BH25 is characterized by its small size and high signal quality. It is suitable for resolutions of up to 3.8pm. Due to the reflective scanning and the small design it is perfectly suited for high accuracy X/Y stages with linear motor drive as well as for measurement applications

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Rotary drives convert the linear movement of the pneumatic cylinders into a rotary movement. Standard rotation angles are 90° – 180° – 270° – 360°. Adjustable by 10°. Special angles are possible.

Request for a quote

FRANKE GMBH

Germany

Franke FDH linear guides are suitable for linear movement tasks, especially in dynamic pick-&-place applications. They have rollers with angular contact ball bearings for the highest acceleration and speed values, for example when using linear motors as the drive source. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

Request for a quote

FRANKE GMBH

Germany

Franke FDH linear guides are suitable for linear movement tasks, especially in dynamic pick-&-place applications. They have rollers with angular contact ball bearings for the highest acceleration and speed values, for example when using linear motors as the drive source. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRANKE GMBH

Germany

Franke FTC linear modules are light, compact and ready-to-install positioning units. The external guide system is moved by an internal spindle or toothed belt drive. Franke FTC linear modules are very versatile. The guide cassette can be designed to meet customer specific requirements.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

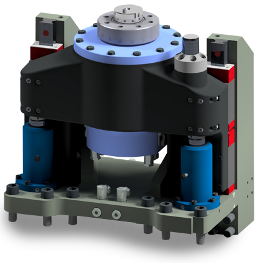

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

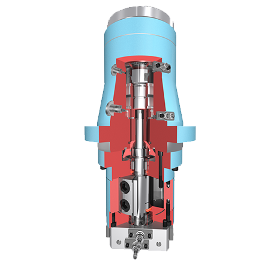

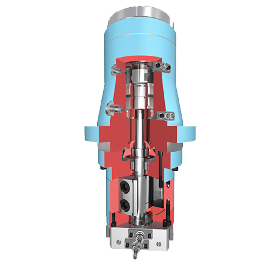

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In the serial arrangement, a vertically aligned linear drive shaft (double-acting linear cylinder) is mounted on the vertically aligned rotary drive shaft (swivel motor), i.e. the piston rod of the cylinder and the output shaft of the swivel motor are mechanically coupled via a movable shaft-hub connection. The pallet holder is lifted by the piston rod, which also serves as a bearing for the pallet holder and safely absorbs all the forces generated during asymmetrical loading. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteResults for

Linear drives - Import exportNumber of results

83 ProductsCountries

Category

- Electric motors and parts (36)

- Automation - systems and equipment (7)

- Measurement - Equipment & Instruments (5)

- Adjustment - machine tools (4)

- Connectors, electronic (4)

- Cylinders, pneumatic (4)

- Bearings - ball, needle and roller (3)

- Internal transport systems (3)

- Machine tools, metal machining - parts and accessories (3)

- Silicones (2)

- Clutches (1)

- Construction - Machines & Equipment (1)

- Electrical & Electronic Components (1)

- Handling - Machines & Equipment (1)

- Laser - cutting and welding machines (1)

- Mechanical engineering - custom work (1)

- Precision measuring instruments (1)

- Robotics (1)

- Sensors (1)