- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lift out

Results for

Lift out - Import export

ROLLON GMBH

Germany

“Lift and move” motion profile with multiple stations and long travel lengths. Synchronized movement system with hard anodized profiles. Polyamide nylon wheels with a rack and pinion system manage horizontal and vertical movement. Column modules carry out lifting movement via a recirculating ball screw drive. The column modules are operated with a single geared motor through a transmission with shafts and corner stops. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Make your forklift even more flexible with the a secutex prong protection coil. After you have secured everything for careful transport, back the lift prongs out of the secutex prongs protection coil and continue to use the forklift normally. Mounting various prongs can be omitted. The secutex prong protection coil is carried by both prongs. The secutex protective coating avoids material damage and prevents the coils from slipping.

Request for a quote

AIS EURELO DEUTSCHLAND GMBH

Germany

Many industrial and manufacturing environments require the use of cranes as an integral process within their operations. At AIS EURELO, we can help you with crane installation at your facility, offering a complete, turnkey crane installation service that includes offloading of the crane at your site, lifting the crane into position, crane installation and crane commissioning. We can also help you with crane relocation projects. Our experienced team of crane experts can provide crane decommissioning and crane removal, lifting the crane out of your facility and loading it to transport, before relocating it anywhere in Europe or beyond.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

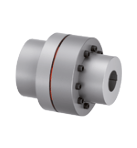

Multi-part design, elastic ring can be replaced without having to axially move the machine The coupling TSCHAN ® TNM G is a torsionally elastic and puncture-proof claw coupling. It balances out angular, radial, and axial shaft misalignments within defined limits. The coupling transfers the torque via pressure loadable, elastic buffers or Perbunan (Pb) which are joined together as an intermediate ring. The elastic intermediate ring can cushion impacts and torsional vibrations; it is oil-tight and electrically conductive. A coupling half is divided in two and allows through this a simple separation of the coupled machine. With the claw ring pulled back it is possible to check the rotational direction of the drive. It is also possible to lift out radially a coupling half with accompanying aggregate. The elastic intermediate ring can be changed without axially shifting the machine. The coupling is usable in every sense of rotation and installation position. TSCHAN ® TNM G Multi-part...

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Nappy changer in stainless steel (AISI 304) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed, handle strip with glossy surface. Table surface molded in polypropylene to fold out with lifting mechanism supported by gas struts. TÜVtested and certified. Approved for public and private use. Delivery includes fixing material. Dimensions 910 x 576 x 135 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESTMARK GMBH

Germany

• with lift-out base • high-quality non-stick coating • uniform browning • for savoury quiches or sweet tarts • of course PFOA-free (according to EU regulation 2017/1000) • heat resistant up to 230 ° C

Request for a quote

ULBRICH GMBH

Germany

The lifting equipment consists of two mobile boogies. Integrated within the superstructure is a hydraulic power pack which drives the two hydraulic cylinders. The cylinders are situated in the highly robust and laterally adjustable lifting blocks. The lifting blocks and the jack contact surfaces (lifting points) can be repositioned along the cross-beam via a spindle. This allows the flexibility to lift and control a number of different types of Locomotive and carriage. Once the carriage has been lifted, the lifting blocks can be locked out using safety bolts which ensure that the height selected is safely maintained. The position of the safety bolts themselves can also be controlled by sensors. An optional function to weigh and calculate the centre of gravity is available upon request. Here, the lifting blocks have been fitted out with “load cells“, which can transfer the load input into a unit of weight. With the accompanying software these values can be evaluated in order to determi

Results for

Lift out - Import exportNumber of results

8 ProductsCountries

Company type