- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- level monitoring

Results for

Level monitoring - Import export

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

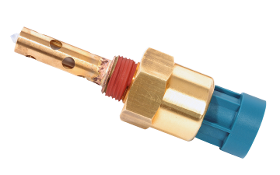

Areas of Application and Advantages BEDIA CLS 10 stands for special versions of our well-proven CLS 40 series for heavy duty applications. Currently, the BEDIA CLS 10 series includes a variety of sensors, which are compatible replacement parts for level switches from Cooper Standard and Robert Shaw which are obsolete nowadays – and this in well proven BEDIA quality. This also includes sensors with 2 complementary CMOS outputs. It should be emphasized that the water sensors with two complementary outputs can be operated with a supply voltage of 4.75 V DC – 32 V DC. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate (at a frequency of approx. 600 kHz). Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

We offer the appropriate interface device for separating, forming, processing, converting and conditioning analog signals. The product portfolio comprises analog signal isolators, isolating transducers, temperature measuring amplifiers, potentiometer amplifiers, trip amplifiers and level monitors - for simple and complex requirements, for Ex- and non-Ex applications, available in the IP20 housing for DIN rail as well as in the compact IP67 housing for decentralized on-site remote control.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Automated emptying system for containers up to approx. 30 liters ▪ Volumetric conveying progressive cavity pump based on the endless piston principle ▪ Pulsation-free and precise emptying and material supply to 1C and 2C dispensing systems ▪ In redundant dosing systems applicable ▪ For medium to high viscosity materials ▪ For structure sensitive, filled, abrasive materials ▪ Application for cylindrical or slightly conical metal and plastic containers ▪ Housing for machine safety and protection against dirt contamination ▪ Automatic retraction and venting the container as well as detection of media surface ▪ 4“-Touch panel with function keys for comfortable setting and parametrization of the system ▪ Externally controllable via Profinet interface ▪ Continuous determination of the position of the follower plate and level monitoring ▪ Adjustable pressure reduction for longer pauses

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

The NR 260 is a capacitive level sensor for monitoring liquids. It is designed for use in fuel cells. The material is also suited to applications in the chemical industry for monitoring aggressive media. The functions for MIN or MAX monitoring as well as other properties (output signal LSS or HSS, response delay etc.) are factory pre-set. The Main Features of the NR 260 are high medium resistance of materials enamel, Hastelloy C4 2.4610 and stainless steel 1.4571 high protection class IP67 with connector short-circuit proof switching output 1 A, high side or low side switch MAX sensor or MIN sensor switch point factory pre-set for the following media: de-ionised water (conductivity < 4,2 μS/cm): 28 mm ± 2 mm tap water (conductivity ≈ 300 μS/cm): 22 mm ± 2 mm other media upon request; switch point adjustment via programmable interface on request

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA intelligent tank sensor ITS 65 is used to monitor the filling levels of oils of any kind. The sensor is able to automatically recognize and what kind of oil (hydaulic oil, engine oil etc.) is present and calibrates itself to it. The capacitative measurement principle permits measurement of levels without mechanically moving parts. This considerably increases stability and operating safety. Mechanics The new tank sensor ITS 65 is characterized by a particularly stable, but light mechanical system specially designed for “Heavy Duty Applications”. The mounting flange and measurement tube are constructed from die cast aluminium. This construction permits the insertion of tank sensors up to 1200 mm in length, without additional support on the tank floor. Analogue Output The analogue output is available as an voltage output with a range from 0 V to 10 V or as an PWM output.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA intelligent tank sensor ITS 60 is used to monitor the filling levels of Diesel fuels. The sensor is able to automatically recognize what kind of Diesel fuel (Bio-Diesel, Summer-/Winter-Diesel etc.) is present and calibrates itself to it. The capacitative measurement principle permits measurement of levels without mechanically moving parts. This considerably increases stability and operating safety. Mechanics The new tank sensor ITS 60 is characterized by a particularly stable, but light mechanical system specially designed for “Heavy Duty Applications”. The mounting flange and measurement tube are constructed from die cast aluminium. This construction permits the insertion of tank sensors up to 1200 mm in length, without additional support on the tank floor. The flange hole distribution is compatible with commercially used tank sensors. This means that this system can be used without expensive conversions.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

Conductive level monitor for the detection of conductive media. With this sensor, the resistance between two electrodes is measured. If a medium shorts both electrodes, the resistance decreases and a switching signal is generated. Buildup is no problem for this sensor.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

—Capacitive proximity switches for the detection of non-metallic and metallic objects —Smooth plastic sleeve —Diameter 20 mm, 34 mm —for counting, position queries of parts or products, for example in furnace technology, chemical industry or plastics processing — with additional PTFE sleeve suitable for level monitoring in tanks

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE microwave filling level monitors monitor the filling level of fluids, powders and granulate with a low DK value and are particularly resistant to adhesion. The MFC sensors are also suited for separation layer detection. The sensitivity is adjustable. The sensors are based on a special variant of microwave frequency shift technology. EGE supplies the sensors in varying lengths up to 1000 mm. The stainless steel and PTFE sensor tip is suited for use in aggressive media.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

Robust and reliable level monitoring for fluids and bulk materials in cylindrical design with thread. The sensors are suited for installation using mounting plates and nuts or adapters in the tank wall. The sensors are based on the proven capacitive principle. The medium to be detected functions as dielectric. The medium in touch with the sensor generates a capacity change. This is converted into a switching signal or an analogue 4...20 mA output signal. EGE filling level sensors in cylindrical design are designed for rough industrial environments with PTFE housing for use in aggressive media. Also available with robust stainless steel thread.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

Capacitive filling level monitors for operation at medium temperatures of up to 230° C. With PTFE or PEEK housing and stainless steel thread for use in aggressive media. The sensors are based on the proven capacitive principle. The medium to be detected functions as dielectric. The medium in touch with the sensor generates a capacity change. This is converted into a switching signal or an analogue 4...20 mA output signal. This applies both to conductive and on-conductive media. With their small design the sensors of this series are well suited for installation in tight spaces. Upon request we supply the sensors with FDA certificate.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE microwave level sensors monitor the filling level of fluids, powders and granulate with a low DK value and are particularly resistant to adhesion. The MFC sensors are also suited for separation layer detection. The sensitivity is adjustable. The sensors are based on a special variant of microwave frequency shift technology. EGE supplies the sensors in varying lengths up to 1000 mm. The stainless steel and PTFE sensor tip is suited for use in aggressive media.

Request for a quote

BDSENSORS GMBH

Germany

The slimline probe LMK 306 with ceramic sensor has been especially designed for the continuous level measurement at confined space conditions. Permissible media are clean or slightly contaminated water and thin fluids. Different cable sheath materials are available in order to achieve maximum media compatibility. Features: — nominal pressure: 0 ... 6 mH2O up to 0 ... 200 mH2O — accuracy: 0.5 % FSO — diameter 17 mm — excellent long term stability — suitable for hydrostatic level measurement e.g. 3/4" pipes — excellent linearity Optional Features: — different cable materials — customer specific versions e.g. special pressure ranges Preferred areas of use: — level measurement at confined space conditions — ground water monitoring — depth or level measurement in wells — drinking water abstraction — level measurement in open and closed tanks

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Reflexion level gauge type 410- PN16-40- with frontally welding ends Ø 20 x 2,6 operating pressurre max. 35 bar Use: This sightglasses suitable for visual inspection of liquid levels in the tank, they enable reliable monitoring of the level.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

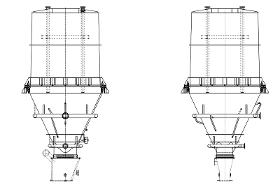

Force-of-gravity separators, which are used as pre-filters or for the separation of large quantities of dust and swarf. Cyclone separator Cyclones are force-of-gravity separators. The separation principle is based on centrifugal force, which is produced by the tangential injection of the raw air. Cyclones are used as pre-filters or for the separation of large quantities of dust and swarf. The degree of separation of a cyclone is not normally sufficient to meet the usual environmental protection requirements. The cyclone exhaust air must be post-filtered in most cases. Product description A cyclone essentially consists of three parts: the intake cylinder, the cone and the immersion tube. In the intake cylinder, the raw air is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air stream and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube. Cyclones are usually welded sheet steel structures. Cellular wheel sluices or, in individual cases, double-gate sluices are used for the pressureless discharge of the material. In order to increase the cyclone effect, or the degree of separation, counter-spirals with a pipe connection can be placed on top of the immersion tube. Further options are, for example, wearing devices, explosion pressure relief devices, control flaps, level monitoring devices and manufacturing in stainless steel or galvanised sheet steel.

Request for a quote

DRIESEN + KERN GMBH

Germany

P-Sense transducers for pressure and temperature can be used both in air and in water or other fluids. Devices come with analog, digital or switching output and can be configured for absolute pressure or gauge pressure measurements. Potential fields of application are water level monitoring or fluid level measurements, e. g. in bodies of water, sewage treatment plants, storage tanks etc. The p-Sense320 probe can be fitted with an RS485 interface instead of an analog output which can optionally be connected to a computer using a RS232 adapter. Connection and data transfer to a PC/notebook can established with the Windows terminal.

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

By specially coordinating goods movements, LNG terminals, and shaker technology, even the smallest drill holes can be optimally flushed and coated. Specialized system technology ensures optimal layer thickness distribution, on both a micro and macro level. By continuously monitoring all process parameters, such as temperatures, flow rates, conductance, pH levels, shaker function, and processing time, we are able to achieve an error rate of almost 0 ppm.

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

It is easy to operate with a recoil start function that provides quick activation. Fuel consumption is low because the variable speed control adjusts engine speed according to load conditions. In addition, the generator can be connected to another and used in parallel to increase overall power capacity without the need for a larger generator. Features: -traction starter -Large fuel tank 10 liters ( run time up to 12 hours) -Engine oil level monitor -Overheating protection -Silenced hood CE compliant noise level -Sockets -Electric key start 12 V -Automatic voltage regulation AVR -Inverter technology, stable voltage and frequency -Instrumentation, voltmeter, hour meter -Circuit breaker -wheels -Motor alarm: low oil level -overload -Intelligent speed control for fuel efficiency -Connections for parallel operation

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Robust, double-walled storage tank made of polyethylene, UV resistant, for outdoor use. max. filling capacity 5000 l; wall thickness approx. 9 mm (inside); anti-leakage warranty 10 years. (incl. pump and accessories) Equipment/accessories: - Self-priming vane pump Panther 72, 230 V. - Diesel filter in metal housing, with water separator - Mechanical counter K33 - Lockable dispensing cabinet with double lock - Wireless level sensor, connected to the monitoring system (leakage indicator) in the interstitial space - Filling hose 1 length 6 m. with automat. A60 nozzle - Lockable filler cap - 16 Service hatch on the outer wall enables tank cleaning to be carried out - Tank vent on the filling lid - Lighting of the dispenser - Electronic overfill protection Dimensions approx. W 2.38 m x H 2.03 m x L 2.95 m Weight (incl. pump equipment) approx. 380 kg Optional: Filling line with overfill protection and tank truck connection Art.

Request for a quote

H. TIMM ELEKTRONIK GMBH

Germany

The Overfill Prevention Controller EUS-2 is the central part of the overfill prevention system according to European VOC Directive 94/63/EC and American API RP 1004. EUS-2 monitors the level sensors at the tanker compartments, the truck grounding and the vapor recovery connection. The filling process is interrupted immediately at the loading gantry, if a critical situation is detected. The controller is able to detect the type of truck installation and activates the required operatingmode automatically. This interoperability allows to load trucks of different carriers.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Intelligent Storage Management With the ISM 400 you can flexibly store 7“, 13“ and 15“ reels, trays, tubes, printed circuit boards, well equipped feeder, solding pastes or screen printing frames manually and monitor their insertion and extraction. The different configuration possibilities of the ISM 400 satisfy the storage needs of the most varied types of components as well as operational and consumable resources of a modern SMT production. With the help of the optional humidity control module it is possible to constantly adjust and monitor the humidity level within the system.

Request for a quote

SIM AUTOMATION GMBH

Germany

- Quality control and safeguarding - Individual test values and criteria - Customer-specific measuring and testing plants - Single measuring systems with manual assembly - Fully integrated and automated testing plants using robots - Optical, acoustic or electrical systems with/ without parts contact, data preparation, analysis Measuring and testing systems we were involved in: - Camera systems with corresponding image processing - Part recognition, positioning, color and surface examination, checking for damages - Optical / tactile / ultrasonic tests using sensors and displacement measurement systems - Leakage and pressure tests - Inspection and monitoring of filling level - Run-out properties and accuracy - Backlash measurement - Electrical tests and measurements - Electrical values, check measurements, switching and opening properties Used in all branches: e.g. pharmaceuticals industry, medical engineering, cosmetics, electronics and automotive industries.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The large storage tank facility provides the opportunity to stock sucient quantities of glue, emulsion, liquid hardener, release agents, etc. This ensures that production runs smoothly Features, function Both the tank volume and the tank design are variable, which means that they may be perfectly adapted to the available space of the site. with devices to prevent overlling. Levels are monitored by pressure or radar sensors visualisation. This enables operators to respond to low quantities in time. between tanks allow maintenance to be carried out on individual components without it being necessory to stop production The downstream transfer systems, which include pumps, lters, sensors and fittings have been adaptod to the medium and are always completely pre assembled

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function A high-performance chip bunker, which transports the most different feed materials trouble-free to the plug screw, is installed in front of the modern refiner plug screw assemblies. The new high-performance chip banker can be retrofitted to any Pallmann Refiner but can also be installed on machines from other manufacturers. Advantages Increased arrangement of the steam nozzles and more precise level monitoring for more effective presteaming of the wood chips Energy savings due to less boiling time of the wood chips Reduced bridging

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

The small handy, portable methane-leak of detection of the company Crowcon is in use to find out gas losses in areas difficult to access or long distances. ATEX-approval for use in CS- areas! Features of LaserMethane Mini: Detection of loss by toughened safety glass Measuring radius up to 100 meter Precisely measuring through laser-technology Light and compact design Response time approx. 0,1 sec. User programmable alarm level High contrast monitor Display in ppm/meter Approvals for LaserMethane Mini: ATEX - approval II 2G Ex ib op-pr/op-is IIA T1 (device) II 2G Ex ib IIA T1 IP54

Request for a quote

GEORG SCHÜNEMANN GMBH

Germany

SAB‘s F450 Self-Cleaning Filter automatical-ly cleans all low viscosity fluids at high output flow rates. No matter if it is during filtration of aggressive fluids, desalination, industrial pro-cess or power station cooling, the F450 will meet the need. This system reliably protects heat exchangers and other downstream com-ponents from clogging and fouling. - Significantly longer service life because of Bernoulli-princip - Continuous filtration without process interruption - Time or pressure differential controlled cleaning process - DN32 up to DN600 - 5 m³/h up to 4400 m³/h - Individual construction with support to material, quantity and position of connections - Filtration degree from 150 µm upwards - pneumatic or electric drives - ATEX-approval - Implementation of control units into higher level control and monitoring systems - Low pressure drop - Operational from 0,7 bar upwards

Request for a quoteResults for

Level monitoring - Import exportNumber of results

31 ProductsCountries

Category

- Sensors (8)

- Inductive sensors (5)

- Automation - systems and equipment (1)

- Dosing - machines and equipment (1)

- Electricity generators (1)

- Explosion-proof - equipment (1)

- Measurement and control instruments (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Palletising machinery (1)

- Storage equipment and systems (1)

- Storage tanks (1)

- Wood veneer - machinery and equipment (1)