- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal part

Results for

Metal part - Import export

3D-MICROMAC AG

Germany

The DMP machine solutions are designed for flexible series production of complex metal components using micro laser sintering. The DMP machine series is the perfect solution to achieve superior detail resolution, highest surface quality, unrivalled accuracy, and very high part density. It offers high flexibility, low operating costs and user friendliness. The system includes a zero point clamping system for easy post-processing at the highest accuracy level and inert gas atmosphere including gas purifying based on industry standards. The DMP systems are able to process non-reactive and reactive materials, e.g. stainless steel, molybdenum, tungsten, titanium, and gold. The Micro Laser Sintering technology has been developed and is continuously improved by 3D MicroPrint GmbH. Superior detail resolution Highest surface quality Unrivalled accuracy Very high part density

Request for a quote

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quote

STARRAG GMBH

Germany

The Bumotec s191V is the combination of proven Swiss made mechanics and stateoftheart CNC control and drive technology. With the CNC Bumotec s191V mill / turn center, precise and complex components can be produced via 5axis machining. Thanks to its stable mechanical concept and its linear drive technology, accuracies of just a few microns can be achieved. The integration of an individually adaptable automatic workpiece change unit, allows the machine to be used for one off prototypes or to run so called «unmanned shifts» without personnel. Many different configurations are available with three to five axes of machining capacity. The thermal stabilization unit almost eliminates warmup cycles when starting or after machining interruptions. Features Linear driven motors and directdriven rotation axis High speed spindles (maximum 40,000 rpm) Smart combination of turning and 5axis machining High thermal stability Automatic tool changer for 90 HSK40 tools

Request for a quote

STARRAG GMBH

Germany

A 4station transfer machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g 4 machining stations Up to 36 tools integrated into the machine

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

STARRAG GMBH

Germany

The vertical lathes of the TVU product line of Berthiez are especially suited for machining engine and turbine components, which are primarily used in the aerospace industry as well as for alternative and classical power generation. The TVU vertical lathes are characterized by a complete cast design, highprecision static and dynamic positioning as well as longlasting reliability. Advantages of the TVU vertical turning lathes are, completely cast iron construction, high static and dynamic axis stability, high accuracies and long term reliability. For higher flexibility the machine can be equipped with several pallet change systems and adaptable milling heads. The optional Yaxis table traverse will permit the turning, milling and grinding of complex components in a single clamping.

Request for a quote

STARRAG GMBH

Germany

The vertical lathes of the TVU product line of Berthiez are especially suited for machining engine and turbine components, which are primarily used in the aerospace industry as well as for alternative and classical power generation. The TVU vertical lathes are characterized by a complete cast design, highprecision static and dynamic positioning as well as longlasting reliability. Advantages of the TVU vertical turning lathes are, completely cast iron construction, high static and dynamic axis stability, high accuracies and long term reliability. For higher flexibility the machine can be equipped with several pallet change systems and adaptable milling heads. The optional Yaxis table traverse will permit the turning, milling and grinding of complex components in a single clamping.

Request for a quote

STARRAG GMBH

Germany

The 5axis Mill / Turn center model s128 is a perfect combination of maximum performance and minimum footprint. On less than 2m², the s128 is a concentrate of high technology; Milling, Turning, Drilling, Engraving, Setting preparation and Diamond cutting processes are possible to produce parts as single unit or as serial manufacturing. The machining of miscellaneous parts from bar or blank and demanding perfect surface quality can be achieved with very short changeover time. Features Compact machine less than 2m² Flexible manufacturing solution Production from bar or blank 5Axis simultaneously

Request for a quote

STARRAG GMBH

Germany

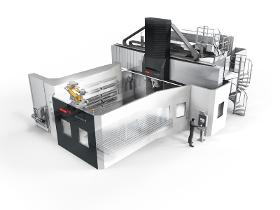

With the T/TF series, Droop+Rein offers gantry machining centres for heavyduty machining in many sectors Applications range from tool and mould making, aircraft component manufacturing and engine manufacturing to general mechanical engineering. Based on the robust, highly accurate and powerful basic machines, the T/TF series offers an extensive system of innovative automation and expansion stages that enable the machines to be adapted flexibly to each machining task. The optional automatically changing forktype milling head makes complex and demanding machining possible. Through extensive application knowhow, a variety of different milling heads are available including vertical milling heads, angle milling heads, and forktype milling heads for positional or simultaneously controlled applications.

Request for a quote

STARRAG GMBH

Germany

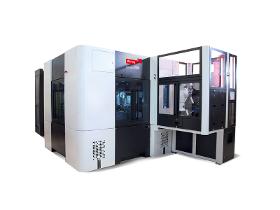

These fiveaxis horizontal machining centres are spacesaving miracles, but they remain true to our stringent quality standards in every respect. They guarantee maximum precision for your work processes thanks to our guiding values of accuracy and rigidity. These are values embodied by Heckert machining centres throughout their decadeslong history on the market.

Request for a quote

STARRAG GMBH

Germany

The flexible and modulardesigned Heckert Large Athletic Series guarantee optimum results in the economic processing of largesized and heavy workpieces with an edge length of up to 3,300 mm and up to 13,000 kg in all material qualities. Available in 4 and 5axis versions

Request for a quote

STARRAG GMBH

Germany

The SIP SPC Series not only provides the user with the ultimate in precision but also with tried and tested sophisticated automation. Investment in SIP technology produces returns, thanks to aboveaverage longterm precision and many years of durability.

Request for a quote

STARRAG GMBH

Germany

The SIP SPC Series not only provides the user with the ultimate in precision but also with tried and tested sophisticated automation. Investment in SIP technology produces returns, thanks to aboveaverage longterm precision and many years of durability.

Request for a quote

STARRAG GMBH

Germany

s230 is an automatic solution for faceting and diamond finishing dials index. s230 production center allows the production of a wide variety on index in various metals. Contrasts of different visual effects are performed by the use of diamond tools or solid carbide tools. The complete solution for small and medium series for finishing index combines multiple operations on a single machine. Features Optical recognition and origin definition of blanks Diamond with the revolver toolholder Machining of LuniNova pockets and micromilling Simple programming interface on Windows A variety of automation systems are available to ensure a high level of autonomy in production

Request for a quote

STARRAG GMBH

Germany

Finishing centers for the jewelry industries, the machines range s210/ s220 combine several processes such as Milling, Engraving, Drilling and Faceting to produce parts for the most demanding key players of the jewelry crafts worldwide. His legendary finishing qualities best fit the requirements in terms of accuracy and ease of use. Features 6 to 8Axis Faceting, engraving, drilling, milling 2 spindles with changer and tool magazine High frequency 45.000min1 spindle Easy changeover of the programs CNC control unit Siemens 840Di

Request for a quote

STARRAG GMBH

Germany

A standalone monostation machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

The compact single column vertical lathe (swing diameters of 1,400 to 2,800 mm) is appropriate not only for turning, but, with additional units, can also be used for drilling, milling and grinding. It means that it is possible, in a single clamping, to carry out a full machining operation on the CONTUMAT VCE and not simply turning. The rigid cast construction on this lathe ensures low vibration and accurate cutting; hydrostatic guide rails damp vibrations even further. The technical design and numerous fitting options mean that Dörries is able to configure an individual machine to every customer.

Request for a quote

STARRAG GMBH

Germany

The compact single column vertical lathe (swing diameters of 1,400 to 2,800 mm) is appropriate not only for turning, but, with additional units, can also be used for drilling, milling and grinding. It means that it is possible, in a single clamping, to carry out a full machining operation on the CONTUMAT VCE and not simply turning. The rigid cast construction on this lathe ensures low vibration and accurate cutting; hydrostatic guide rails damp vibrations even further. The technical design and numerous fitting options mean that Dörries is able to configure an individual machine to every customer.

Request for a quote

STARRAG GMBH

Germany

The compact single column vertical lathe (swing diameters of 1,400 to 2,800 mm) is appropriate not only for turning, but, with additional units, can also be used for drilling, milling and grinding. It means that it is possible, in a single clamping, to carry out a full machining operation on the CONTUMAT VCE and not simply turning. The rigid cast construction on this lathe ensures low vibration and accurate cutting; hydrostatic guide rails damp vibrations even further. The technical design and numerous fitting options mean that Dörries is able to configure an individual machine to every customer.

Request for a quote

STARRAG GMBH

Germany

The Dörries CONTUMAT VC series, designed as a double column portal system, is ideal for larger swing diameters of 3,500 to 12,000 mm. The VC range combines all of the advantages of the VCE range with the ability to machine large scale components just as effectively. The positive construction properties of the smaller range are taken over here in correspondingly dimensioned main components. The range also provides high levels of flexibility by combining standard modules, providing the customer with a solution tailored to suit their individual needs. The closed portal construction of the double column vertical lathe guarantees high intrinsic rigidity, while the proven cast construction ensures excellent damping and thermostability. Thanks to these characteristics customers obtain a lathe that provides high machining accuracy, with a long service life

Request for a quote

STARRAG GMBH

Germany

The Dörries CONTUMAT VC series, designed as a double column portal system, is ideal for larger swing diameters of 3,500 to 12,000 mm. The VC range combines all of the advantages of the VCE range with the ability to machine large scale components just as effectively. The positive construction properties of the smaller range are taken over here in correspondingly dimensioned main components. The range also provides high levels of flexibility by combining standard modules, providing the customer with a solution tailored to suit their individual needs. The closed portal construction of the double column vertical lathe guarantees high intrinsic rigidity, while the proven cast construction ensures excellent damping and thermostability. Thanks to these characteristics customers obtain a lathe that provides high machining accuracy, with a long service life.

Request for a quote

STARRAG GMBH

Germany

The Dörries CONTUMAT VC series, designed as a double column portal system, is ideal for larger swing diameters of 3,500 to 12,000 mm. The VC range combines all of the advantages of the VCE range with the ability to machine large scale components just as effectively. The positive construction properties of the smaller range are taken over here in correspondingly dimensioned main components. The range also provides high levels of flexibility by combining standard modules, providing the customer with a solution tailored to suit their individual needs. The closed portal construction of the double column vertical lathe guarantees high intrinsic rigidity, while the proven cast construction ensures excellent damping and thermostability. Thanks to these characteristics customers obtain a lathe that provides high machining accuracy, with a long service life.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the FOGS NEO series, Droop+Rein has developed a powerful machine concept for complex machining. The range of services covers processes from machining standard geometries and prefinishing contours to final finishing. For dynamic machining with the highest feed rates, the concept caters for the movement and acceleration of constant masses, regardless of workpiece size and weight. Dynamic and flexible With its new, highly flexible and fast Caxis (±400°), the Droop+Rein FOGS NEO highspeed machining centre is ideal for the complete multifunctional machining of very large workpieces. Of course, the series also features automatic pallet or tool change, tool diameter and length measurement and automatic billing of contour deviations. Thanks to a variety of components and peripheral devices from their modular system, Droop+Rein can create an efficient and processoriented overall system that is tailored to the customer.

Request for a quote

STARRAG GMBH

Germany

In order to produce heavy workpieces with limited available space, Droop+Rein combined the FOGS and TF machine types which are already established on the market into a new machine concept. With the FOGS HD, Droop+Rein offers a machining centre for heavyduty machining, which features high quality and precision at the same time. The constant dynamic dimensions of the Droop+Rein FOGS HD enables the user to use the machine for unmanned finishing e.g. at night or at the weekend. The Droop+Rein FOGS HD is designed for large components, as the traverse paths show (Xaxis 3,000 to 31,000 mm; Yaxis 3,000 to 6,000 mm; Zaxis 1,500 to 2,500 mm). It covers all machining operations within typical toolmaking. The FOGS HD is an efficient (50 to 100 kW (S1 operation)), precise machining highgantry machine with fast and dynamical axes and extreme high torque (2,400 to 7,500 Nm).

Request for a quote

STARRAG GMBH

Germany

Flexibility, efficiency and precision play a very important role for machine manufacturers and tool builders, especially when dealing with large components. These three requirements led to the development of the gantry machining centre TS/TFS NEO with a fixed and movable crossbeam, whereby the customer chooses the table designs, controls and milling units suitable for them on a modular basis. The TS/TFS NEO features a new milling unit and a modified Caxis (±400°) which, thanks to its enormous flexibility, can be used for efficient production of highly precise machine parts. The large number of automatically changeable milling heads increases the machine's flexibility within its scope of application. The TFS also allows automatic tool or spindle changing and tool or workpiece measurement.

Request for a quoteResults for

Metal part - Import exportNumber of results

115 ProductsCountries

Company type