- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting

Results for

Cutting - Import export

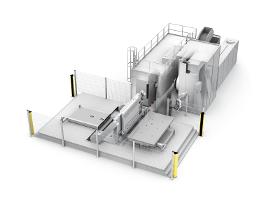

STARRAG GMBH

Germany

Scharmann has developed the ECOSPEED F for highspeed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED. What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the Xaxis, which enables component loading and unloading during the machining cycle

Request for a quote

3D-MICROMAC AG

Germany

- Formats from 1/2 to 1/6 cells and sizes up to M12 - Free-form cutting - Power increase of up to 2W through TLS technology 3D-Micromac's patented laser technology for direct cutting of solar cells is the leading method for cutting cells. When conventional cutting methods reach their limits, TLS technology with ultra-short pulses comes into play. Excellent cutting qualities with high reproducibility and accuracy can be guaranteed. Whether half-cell, third-cell, quarter-cell or the trend-setting six-cell. The great flexibility of TLS technology makes it possible to provide our customers with comprehensive support. Adaptation in the number of cell cuts, variation in the size of the substrates up to 220mm or a high flexibility in the freedom of shape. From silicon-based cell types such as PERC, TOPCon, HJT to IBC, the processing of your mono- and polychristaline photovoltaic cells is possible.

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microSHAPE™ laser system is designed for the processing of large and flat substrates with high accuracy. The highly versatile system allows the combination of different laser processes in a single machine. In addition, it is capable of processing with multiple working heads – this parallel processing makes higher throughputs achievable. microSHAPE™ is an industry proven solution for all kinds of ablative and non-ablative processes. These include cutting, selective removal of thin films, and structuring processes like engraving and marking. The microSHAPE™ system is suitable for machining a variety of materials, e.g. glass, metals, polymer, ceramics, display stacks, and coated substrates. Free form cutting with extraordinary quality Damage free cutting edges Contactless processing enables minimal cost of ownership Cutting speed up to 1.5 m/sec Laser sources according to customer requirements Up to 3 independent beam paths

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cutting - Import exportNumber of results

3 ProductsCountries

Company type