- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines

Results for

Machines - Import export

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

With our ECM machines of the ES series, your entry into your own electrochemical machining is made easier. Whether as a stand-alone system or integrated into your existing production process - through standardization and modularised generator technology, this machine type finds a wide area of application. In spite of uniformity, the machines and devices are designed to meet your requirements and optimized by our technological know-how.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Due to their compact and flexible design, LS series laser machines guarantee an easy entry into the world of laser processing. We offer manual and automated solutions: - Palletising systems - Bar and coil feed systems - Pick-and-place systems - Robots You can realize the following laser material processing with the LS series: - laser machining for welding, clean welding, cutting, drilling, hardening, and structuring - micro processing - integration of CO2 , Nd: YAG, diode, fibre or disk-type lasers and ultra-short pulsed laser Please get furher information at Download.

Request for a quote

STARRAG GMBH

Germany

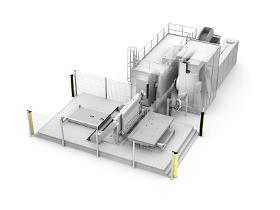

Ecospeed is the synonym for the most economic method of machining complex aluminium structural components in the aerospace industry. Based around its’ unique parallel kinematics Sprint Z3 machining head, Ecospeed represents by far the most productive solution for the high performance cutting of monolithic aluminium aerostructures. The Ecospeed family has been continuously developed to meet market demands. New challenges imposed by the market are implemented within a team framework, by maintaining intensive contact with end users. Yet another recent customerdriven requirement placed on the Starrag Technology GmbH management board was to supply an optimized economic Ecospeed variant for machining long and narrow structural components at high cutting rates and using complex 5axis geometries with 5side access to the work piece.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

With the addition of a moveable table, traversing through the twin column portal design of the VC machine range, the VCV provides the ultimate flexibility for machining large components. In addition to the «on center» machining capability of a standard lathe the VCV machines are able to machine eccentric features. With the use of our extensive range of standard milling and drilling attachments, the VCV machine range is capable of full 5 sided machining of components up to 12,000 mm in diameter and 350 tons in weight. On machines with a Yaxis the component can be machined in any position. The turning table is set on a sliding bed. The default Yaxis travel corresponds to the swing diameter of the machine size, but can be tailored to suit any application.

Request for a quote

STARRAG GMBH

Germany

Gantry design For machining of largest and heaviest workpieces Droop+Rein offers a floor guided gantry machine line. Best accessibility and utilisation of floor space for largest workpieces combined with highest flexibility in size and configuration. Cross rail, moveable (GS) or fixed (GFS) Economic machining of largest components – flexible, dynamic and precise Floor space savings compared to table moving machines In line with the modular principle – various controls, table configurations, milling head/spindles and tool changer configurations

Request for a quote

STARRAG GMBH

Germany

Flexibility, efficiency and precision play a very important role for machine manufacturers and tool builders, especially when dealing with large components. These three requirements led to the development of the gantry machining centre TS/TFS NEO with a fixed and movable crossbeam, whereby the customer chooses the table designs, controls and milling units suitable for them on a modular basis. The TS/TFS NEO features a new milling unit and a modified Caxis (±400°) which, thanks to its enormous flexibility, can be used for efficient production of highly precise machine parts. The large number of automatically changeable milling heads increases the machine's flexibility within its scope of application. The TFS also allows automatic tool or spindle changing and tool or workpiece measurement.

Request for a quote

STARRAG GMBH

Germany

No matter if it is called a «Blisk» (bladed disk) or an «IBR» (integrally bladed rotor), no matter if it is single stage or multi stage, Starrag’s dedicated machine concept of the NB series provides the best solution for efficiently machining these parts. Blisks made from Titanium, Nickelbased superalloys and the Blisks made of blade steels for stationary gas turbines triggered the development of the NB series. For all the necessary manufacturing operations Starrag provides the benchmark Efficient roughing for Blisks machined from solid, adaptive machining for friction welded Blisks, high dynamic finishing of the airfoils in point contact. Shortest cycle times and zero scrap rate production are achievable on the Starrag NB series. The NB series is based on the very successful Starrag LX series.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The LX series was specifically designed for the highprecision, efficient fiveaxis machining of turbine blades. This ultramodern machining platform is the result of decades of experience in the development of machine tools, CAM systems and special tools combined with our inhouse expertise in the prototype and series production of turbine blades.

Request for a quote

STARRAG GMBH

Germany

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options

Request for a quote

STARRAG GMBH

Germany

Scharmann has developed the ECOSPEED F for highspeed machining of mediumsized aluminium structural components. The horizontal spindle arrangement, the vertical pallet arrangement and the Sprint Z3 parallel kinematic machining head, which delivers high travel speeds (50 m/min) and accelerations (9.81 m/s²), all come from the successful ECOSPEED. What sets the F version apart from the standard ECOSPEED is that the machine column is stationary. The pallet travels in the X direction on the vertically arranged table group. The ECOSPEED F is equipped with a rotating double pallet station, located parallel to the Xaxis, which enables component loading and unloading during the machining cycle.

Request for a quote

STARRAG GMBH

Germany

High performance 6 axis machining center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis mill turn center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

High performance 6 axis machining center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis mill turn center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance 6axis machining center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis machining center for aluminum structures Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis mill turn center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

High performance simultaneous 5 axis trunnion machining center The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quote

STARRAG GMBH

Germany

Efficient high performance machining requires a rugged machine buildup without weakness. All technical parameters such as axis strokes, forces, torques and accelerations are set according to application requirements. The design of the STC X series has no bottleneck reducing the maximum possible material removal rates. With its design, unmatched productivity is possible. The STC X machine enhancement is ever ongoing. The goal is to continuously increase the customer benefits, i. e. increase productivity, increase accuracy or expand the application options.

Request for a quote

STARRAG GMBH

Germany

The STC series has been designed to provide unrivalled economy in the machining of the most demanding structural parts, multiblades and casings with long cycle times, and provide the customer with a whole host of practical options. These machining centers have excellent static and dynamic properties as well as a tried and tested rotatable head, making them the benchmark for heavy chip removal in titanium and Inconel part for the aerospace and power generation industries.

Request for a quoteResults for

Machines - Import exportNumber of results

120 ProductsCountries

Company type