- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser in

Results for

Laser in - Import export

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Do you have individual requirements for your laser processing center that our standard laser system of the LS series cannot meet? We develop together with our customers from stand-alone systems to integration into existing lines. In doing so, system know-how meets automation and laser technology: - robot solutions - portal variants - rotary table machines - sliding table systems - scanner solutions - integrated solutions based on VARIOMODUL® or, - at your request, on standard laser machines of the LS series For further information please take a look at our homepage.

Request for a quote

SUVIS GMBH

Germany

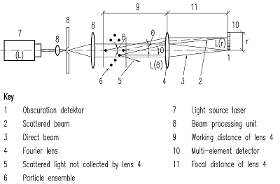

In various chemical or physical and technical processes particles of the order of 1 μm up to a few mm in size appear, whose size distribution is decisive or important for the process. There are many technical examples like in food production, pharmacy, process engineering, fuel burning in turbines, motors etc., slurry burning, and cosmetics. The laser diffraction particle sizer is capable to measure a particle size distribution from a collective of particles like a spray and to appropriately process, describe, and present it. The particle material may be solid or liquid in a gas or gas like air bubbles in a liquid. For the measurement it is only important, that the optical properties of the continuous and the dispersed phase are different. The laser diffraction particle sizer offers the advantage of a fast and non invasive measurement in a wide range of particle sizes. Especially in case of sprays or suspensions this method has become a standard measurement tool.

Request for a quote

SUVIS GMBH

Germany

The measurement technique of LaserDopplerVelocimetry (LDV) is one of the most frequently applied modern measurement techniques in fluid mechanics to perform accurate local flow velocity measurements, which exhibits the advantage of a very high local and temporal resolution. Our technical department offers excellent conditions to perform such measurements (LDV).

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Due to their compact and flexible design, LS series laser machines guarantee an easy entry into the world of laser processing. We offer manual and automated solutions: - Palletising systems - Bar and coil feed systems - Pick-and-place systems - Robots You can realize the following laser material processing with the LS series: - laser machining for welding, clean welding, cutting, drilling, hardening, and structuring - micro processing - integration of CO2 , Nd: YAG, diode, fibre or disk-type lasers and ultra-short pulsed laser Please get furher information at Download.

Request for a quote

3D-MICROMAC AG

Germany

Besides the processing of rigid and flexible materials on rigid substrates, we also offer the processing of flexible materials using sheet-to-sheet or roll-to-roll processes: - Laser micro structuring and ablation - Laser processing “on-the-fly” or “step and repeat” - Roll width up to 300 mm possible

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

3D-MICROMAC AG

Germany

Applications: - Laser cutting, dicing, and filamentation - Laser drilling – available as trepanning or percussion process - Laser micro structuring and ablation, e.g. with FSLA technology - Laser micro engraving, both on the substrate surface and as sub surface engraving in transparent materials Laser-Lift-Off (LLO) using DPSS laser and scanner systems Materials: ceramics, metals, polymers, glass materials, semiconductors, compound material

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microMARK™ MCL is a compact and maintenance free DPSS laser system to meet customer’s demand for high quality laser engraving with significantly decreased cost of ownership. The system is utilized for visible, invisible as well as for technical engravings of all kind of spectacle lenses as well as marking of hard and soft contact lenses. The use of a UV DPSS laser source achieves a high quality marking result comparable to excimer laser engravings. High quality laser engraving Accurate contrast adjustment Low investment and operating costs Maintenance free laser source Plug-and-play replacement of main components directly by the customer High quality engraving with accurate contrast adjustment on a variety of spectacle lenses and coatings

Request for a quote

3D-MICROMAC AG

Germany

The microMARK™ MCF is a premium engraving system. Using an UV excimer laser results in a superior engraving quality considering all cosmetic aspects – without any heat affection and micro cracks. The system is suitable for marking of all kinds of materials and coatings including highindex, tinted, and coated lenses. The microMARK™ MCF is the right choice for concave or convex as well as for blocked and unblocked lenses. The industryapproved system guarantees maximum throughput and availability. Premiumquality excimer laser marking Technical engraving and branding on all kinds of lenses and coatings UDI marking of hard and soft contact lenses Maximum throughput by automatic handling Superior availability by second laser source

Request for a quote

3D-MICROMAC AG

Germany

The production of ophthalmic lenses requires different marking processes, e.g. technical engraving and branding for spectacle lenses as well as UDI marking for contact lenses. 3DMicromac offers ophthalmic marking solutions for laser engraving of all types of ophthalmic lenses, e.g. prescription and sunglasses, or contact lenses. All systems use UV lasers for permanent marking and guarantee Highest engraving precision Accurate contrast adjustment Reliable process stability Maximum throughput Top availability Flexibility in system configuration and Simple retrofitting. 3DMicromac‘s customers can choose between premium quality excimer laser systems and high quality maintenance free DPSS laser systems. Both are suitable for the production of technical engravings and visible branding on blocked and unblocked lenses, as well as contact lenses. The microMARK™ MCF excimer laser system generates the engravings by cold laser ablation of 193 nm UV radiation.

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microSTRUCT™ C is a highly flexible laser micromachining system predominantly used in product development and applied research. Superior flexibility makes the system ideally suited for laser structuring, cutting, drilling and welding applications on a variety of substrates, e.g. metals, alloys, transparent and biological material, ceramics and thin film compound systems. The microSTRUCT™ C offers a maximal degree of freedom regarding the positioning of the substrates. Flexible, stable and repeatable machining results Two independent and free configurable working areas with various optical setups Open system concept for the integration of different laser sources High range of software functions (Masterscript) User friendly, flexible, upgradeable system

Request for a quote

3D-MICROMAC AG

Germany

The DMP machine solutions are designed for flexible series production of complex metal components using micro laser sintering. The DMP machine series is the perfect solution to achieve superior detail resolution, highest surface quality, unrivalled accuracy, and very high part density. It offers high flexibility, low operating costs and user friendliness. The system includes a zero point clamping system for easy post-processing at the highest accuracy level and inert gas atmosphere including gas purifying based on industry standards. The DMP systems are able to process non-reactive and reactive materials, e.g. stainless steel, molybdenum, tungsten, titanium, and gold. The Micro Laser Sintering technology has been developed and is continuously improved by 3D MicroPrint GmbH. Superior detail resolution Highest surface quality Unrivalled accuracy Very high part density

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac‘s microPRO™ is an adaptable laser micromachining system mainly used in industrial production. Its high versatility makes the system perfectly suited for industrial laser micromachining tasks such as laser structuring, cutting, and drilling applications. Furthermore, it is suitable for a variety of materials, e.g., metals, alloys, transparent and biological substrates, ceramics, and thin film compound systems. The microPRO™ is available with an automatic handling system for wafers, cassettes, trays, etc The microPRO™ enables the laser processing of various substrates. Due to the integration of different technology modules, the platform can be adapted to customers’ requirements. Configuration packages may include High speed cutting Drilling Engraving Structuring and modification Laser Lift Off (LLO) Cylindrical machining Customized solutions

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac’s microMIRA™ LLO system provides highly uniform, force free lift off of different layers on wafers at high processing speed. The unique line beam system is built on a highly customizable platform that can incorporate different laser sources, wavelengths and beam paths to meet each customer’s unique requirements. The laser system can be used for a variety of applications, such as GaN lift off from glass and sapphire substrates in microLED display manufacturing as well as in semiconductor manufacturing. Additional applications include laser annealing and crystallization for surface modification. Force free and extremely fast line beam laser processing No damage due to thermo-mechanical effects Low production costs Elimination of costly and polluting wet chemical processes Integration of adjacent manufacturing steps for higher fab productivity

Request for a quote

3D-MICROMAC AG

Germany

The microPRO™ XS system provides laser annealing with high repeatability and throughput in a versatile system. Combining a state-of-the-art laser optic module with 3DMicromac’s modular processing platform, the microPRO XS is ideally suited for ohmic contact formation (OCF) in silicon carbide (SiC) power devices. The microPRO™ XS for OCF features a UV wavelength diode pumped solid-state (DPSS) laser source with nanosecond pulses and spot scanning to process the entire metalized backside of SiC wafers. It forms ohmic interfaces and cures grinding defects, while preventing the generation of large carbon clusters and heat related damage to the frontside of the wafer. Best in class cost per wafer High throughput – 150mm wafers can be processed in a single step Flexible recipe programming and wide parameter range.

Request for a quote

3D-MICROMAC AG

Germany

3DMicromac’s brand new microCETI™ uses the most innovative LIFT (Laser Induced Forward Transfer) laser process, which is an essential factor in the process chain for manufacturing microLED displays. The fully integrated laser system is characterised by its compact footprint and high variability. The microCETI™ enables the transfer of hundreds of millions of microLEDs without the use of mechanical forces, thereby ensuring that microLEDs of almost any shape and size can be transferred. This ensures cost-effective production of microLED displays. Most cost-effective production of microLED displays Unique LIFT module Highest transfer rate ten times faster than competing technologies Flexible software for integration into production lines Handling options for wafers (up to 8″) and sheets (up to Gen.2)

Request for a quoteResults for

Laser in - Import exportNumber of results

16 ProductsCountries

Company type