- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- handles

Results for

Handles - Import export

ARINKO BAUTZEN GMBH

Germany

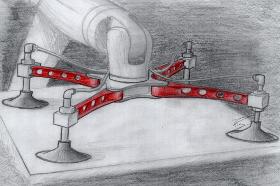

In cooperation with our system partners, we offer you various all-around solutions in the field of handling systems in plant engineering & conveyor technology. In addition to these complete solutions, we also take on the development of various plant parts and/or system components: Manipulators, grippers Transfer stations Safety equipment Workpiece carriers Control cabinets Peripheral equipment Podiums, stairs Media transfer Feeder systems Ejector systems Manual workstations Design focal points: Design & constructional drafts Use of pneumatic and/or electric drives Space-saving lifting stations Construction in accordance with relevant guidelines and regulations Static & dynamic calculation of the construction Material & weight optimization of existing and new systems Project planning to initial start-up of complete automation solutions Optimization and conversion of existing systems

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Door handle with lock for wheel loader FERRUM. Will be delivered like shown.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

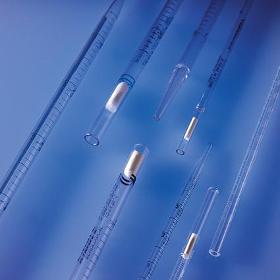

Higher performance and aerosol protection with customized solutions Protect serological pipettes and samples from contamination, fast draw uptake, and unintentional sample expulsion with a family of customizable aerosol barrier filters. Tailored to meet the correct fit, air flow, and volume placement within your pipettes, our serological filters protect lab personnel, maintain productivity and: Safeguard samples –Use aerosol barrier filters versus use of cotton or colored plugs. Improve quality and safety–Reduces fast draw sample uptake and stop samples from exiting the pipette. Minimize accidental exposure–Decreases exposure to hazardous substances and the need for internal syringe filters.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Greater protection from accidental overfilling and spillage Create a protective barrier from accidental overfilling of the pipette and blood spillage by using POREX® ESR Filters (Erythrocyte Sedimentation Rate). To help improve productivity and safety of lab personnel, these filters: Avoid accidental overfilling–Ensures and maintains the proper level of blood sample. Prevent leakages–Stops hazardous substances and blood from escaping through the top of the pipette. Provide control and safety–Reduces exposure to bloodborne pathogens.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

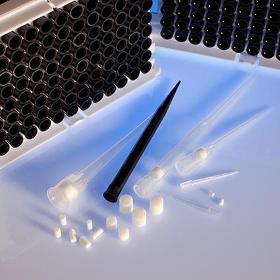

Stronger protection from contamination for pipetters and samples POREX® Pipette Cone Filters help prevent samples, and the pipette’s internal mechanisms and components, from fluid and liquid vapor contamination. Used at the pipette shaft base, these inert, hydrophobic filter tips are optimized for fit, function, resilience, and porosity. Backed by the Certified Pure Porex™ program, our filter tips: Protect pipetter’s internal components –Serves as a final interferent barrier. Prevent contamination–Protects against aerosols and sample cross-contamination. Prolongs product lifetime–Reduces chance for contamination which lowers the need for pipetter maintenance.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximum consistency in airflow, filter purity, and aerosol containment POREX® Automation Certified Pipette Tip Filters are customized and optimized to meet the fit, air flow, and volume placement of your specific robotic and automated liquid-handling instruments, sample processors and dispensing systems. To streamline laboratory operations and production, these automation and robotic pipette tip filters are backed by the Certified Pure Porex™ Program and: Maximize air flow –Delivers optimal dispensing and pipetting performance across a wide range of liquid volumes. Prevent cross-contamination–Eliminates aerosol bypass and sample carryover. Increase sample throughput–Provides tighter tolerance control for increasing laboratory workflow and reducing instrument downtime.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

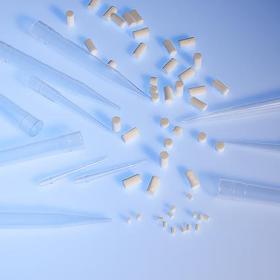

Greater protection from aerosols and aspirated liquids Our new FORTRESS™ Pipette Tip Filters offer a liquid-sealing barrier devoid of any contaminates or additives that can cause PCR, molecular, or analytical methodology and protocol issues. Specifically designed to protect the sample and the pipetter from harmful aerosols generated during the pipetting process or from liquid aspirated into pipette tips, our filters: Ensure purity –Non-leachable and extractable sample recovery is backed by the Certified Pure Porex™ program of independent analytical, clinical, and life science testing. Protect sample integrity–Seals out aerosols and liquid contaminates while preventing cross-contamination and sample carryover. Improve accuracy and precision–Design is optimized for maximum consistency in air flow, form, fit, and function across a broad spectrum of pipetting volumes.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Inner door handle for wheel loader FERRUM. Will be delivered like shown.

Request for a quote

STARRAG GMBH

Germany

Finishing centers for the jewelry industries, the machines range s210/ s220 combine several processes such as Milling, Engraving, Drilling and Faceting to produce parts for the most demanding key players of the jewelry crafts worldwide. His legendary finishing qualities best fit the requirements in terms of accuracy and ease of use. Features 6 to 8Axis Faceting, engraving, drilling, milling 2 spindles with changer and tool magazine High frequency 45.000min1 spindle Easy changeover of the programs CNC control unit Siemens 840Di

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

3D-MICROMAC AG

Germany

3DMicromac‘s microPRO™ is an adaptable laser micromachining system mainly used in industrial production. Its high versatility makes the system perfectly suited for industrial laser micromachining tasks such as laser structuring, cutting, and drilling applications. Furthermore, it is suitable for a variety of materials, e.g., metals, alloys, transparent and biological substrates, ceramics, and thin film compound systems. The microPRO™ is available with an automatic handling system for wafers, cassettes, trays, etc The microPRO™ enables the laser processing of various substrates. Due to the integration of different technology modules, the platform can be adapted to customers’ requirements. Configuration packages may include High speed cutting Drilling Engraving Structuring and modification Laser Lift Off (LLO) Cylindrical machining Customized solutions

Request for a quoteResults for

Handles - Import exportNumber of results

19 ProductsCountries

Company type