- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas on

Results for

Gas on - Import export

POREX TECHNOLOGIES GMBH

Germany

Separate water easily from your oil and gas streams From bonded fiber to sintered porous media, Porex creates media to separate or filter water from oil and gas streams. Specifically designed for your oil and gas application, our water separation media: Reduce material usage - Porex bonded fiber material products can replace the need for multiple medi layers commonly found in oil/water separation filters. Self support - Filters can be self-supporting and customized into various shapes and sizes. request sample ask an engineer

Request for a quote

MEDIZIN- UND LABORTECHNIK ENGINEERING GMBH DRESDEN

Germany

thick rubber stopper

Request for a quote

SUVIS GMBH

Germany

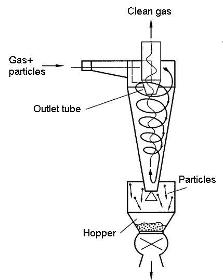

The Suvis GmbH also deals with the application of modern numerical methods for the lay out and optimisation of various separator types like cyclones. A typical application of these computation methods is the computer aided investigation of particle separation from gases in cyclones. The prediction of the separation efficiency allows the reliable optimisation of conventional cyclones and the development of completely novel high efficiency cyclones. With that, very often expensive filter units, wet cleaner, or costly electro filters can be replaced or completed. When applying numerical methods (CFD simulations) to cyclones one encounters the problem of strong curvature of the stream lines because of the resulting strong swirl flow and the abrupt change of flow direction towards the outlet tube. This means that the assumption of isotropic turbulence is not useful anymore.

Request for a quote

SUVIS GMBH

Germany

Hydro cyclone units are applied in order to separate coarse and fine solid particles from liquids . These type of separators are particularly capable of separating sand, starch, and other finely distributed materials. With hydro cyclones it is possible to separate fine particles online during the process. Hydro cyclone units are used to separate, classify, and to thicken suspensions. Also, these units are used to purify ores and minerals. Also, in fibre technique and paper industry they are applied in purification processes to separate dirt. Hydro cyclones are frequently run in parallel mode. The lay out and design of hydro cyclones are performed empirically similar to the duct cyclones. In the lower flow region of a hydro cyclone an air swirl forms during the separation process, which is not substantially influencing the cyclone flow. Because of the large dimension of the cyclone, wall friction has much more influence on the flow.

Request for a quote

SUVIS GMBH

Germany

The gas cyclone belongs to the mostly applied technical separators, because it has applicationwise some fundamental advantages. One of them is certainly the fact that its construction does not show any movable components. For the large variety of different kinds of dispersed (particulate) phases (for example dust particles, metal chips, wooden waste, liquid droplets) and different gas conditions (pressure, temperature) the lay out and computation of a cyclone is still a complex task. Suvis has specialised in the development and lay out of cyclone separators and can offer professional solutions and consulting in the area of gas cyclones. Many years of experience gained through numerous cyclone development projects results in optimal solutions for our customers. A cyclone separator applies centrifugal forces and represents an effective apparatus for separating gas, liquid or solid particles from a continuous phase in chemical, process or environmental engineering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quoteResults for

Gas on - Import exportNumber of results

7 ProductsCountries

Company type

Category