- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser stripping

Results for

Laser stripping - Import export

DIETZ GMBH

Germany

To ensure safe transport and enable an easy handover of the products during later industrial processes and assembly, we ship our springs and sub-assemblies in special packaging. Any conceivable special packaging is adapted precisely to the product in question, e.g. blister or polyethylene packaging. Tube packaging: Compression springs are transported in tube packaging. Tube packaging ensures that they can be inserted without problems, down to the last spring. Sub-assemblies, bent strip parts and laser-generated samples are transported in blister or polyethylene packaging to protect them during transport and storage. Modifying specific extraction mechanisms: We would also be pleased to assist you with our expertise regarding the modification of specific extraction mechanisms. This eliminates downtime of highly complex assembly equipment caused by springs getting caught up in one another.

Request for a quote

MICRO-EPSILON

Germany

thicknessGAUGE C.LP sensor systems use laser profile scanners for the thickness measurement. These scanners project a laser line onto the surface to be measured. The laser line compensates for strip tilting and enables profile averaging. The laser line measuring technique makes it possible to measure the thickness of structured materials such as embossed surfaces and perforated plates.

Request for a quote

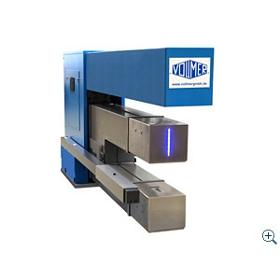

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Laser stripping - Import exportNumber of results

3 ProductsCountries

Company type