- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- labels for bottles

Results for

Labels for bottles - Import export

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Thanks to the TNC-F model series, semi-automatic labelling of shaped bottles becomes very easy. The front and back labels should be on a carrier material. The product is inserted into a product pickup device. As soon as the 2-hand operation is activated, the system starts to pick up the product in the two format pucks, rotates and aligns the product before the front and back labels are applied exactly to the desired positions. By exchanging the format parts of the product pick-up device, cylindrical or angular products can also be processed and labelled with several labels in addition to the shaped bottles.

Request for a quote

SCHREIBER ESSENZEN GMBH & CO. KG

Germany

Focus on high volume b2b, white label, contract bottling.

Request for a quote

SCHREIBER ESSENZEN GMBH & CO. KG

Germany

Focus on high volume b2b, white label, contract bottling. Flexible packaging solutions Our caramel colouring (E 150d) is produced under the certification FSSC 22000.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

fully automatic Sleeve applicator designed for application of sleeve labels on cups, jars or bottles, empty or full, of any material, shape and/or size

Request for a quote

SCHREIBER ESSENZEN GMBH & CO. KG

Germany

Our services for large-scale and commercial customers •Product and fragrance development according to your requirements •Various bottles, closures and cartons to choose from •Marketing service (label, name, design etc.) •Safety data sheets in many languages •Export and sales support within and outside the EU •Information service on transport regulations, safety data sheets, product liability •Attractive gift boxes and individual packaging •Third-party filling and production of feed supplements •Fast and flexible delivery Would you like to create a unique sauna fragrance for your company-clients? We will help you develop your own signature fragrance or adapt an existing fragrance to your needs. Whether you are looking for a new fragrance, label, bottle or you have a question about sales or exports – we are always prepared for your questions and wishes

Request for a quote

TINY TECHNOLOGIES GMBH

Germany

Our TINY White Label range offers diverse active ingredient liquids with 80% bioavailability via TINYsphere® technologies. Besides the notable TINYsphere® advantage, you can enhance TINY White Label products uniquely. Consider distinct colors, flavors, or ingredients. Opt for different containers or packaging, aligning perfectly with your brand. Choose between bulk liquid delivery or Full Service, including bottles, caps, labels, filling, and cartons. Our products adhere to IFS standards, crafted with German universities, vegan, and free from artificial ingredients. We're here for your needs, offering personal consultations. Call us at: +49 (0) 40 87409824.

Request for a quote

TINY TECHNOLOGIES GMBH

Germany

Our product range features highly bioavailable TINYsphere® technology-enhanced liquid supplements, offered in bulk or conveniently pre-filled 10/30ml TINY White Label bottles made of brown glass and sealed with black/white spray or dropper caps. Additionally, TINY offers Solids (capsules) in attractive brown wide-mouth bottles with black/white screw caps. Going beyond, TINY extends its support by providing Full Service, encompassing customized labeling and packaging according to your design, enabling impactful product launches. Our IFS-compliant products are developed in partnership with German universities, ensuring quality. They are fully vegan, devoid of artificial ingredients. For further assistance and personalized guidance, feel free to contact us at Telephone: +49 (0) 40 87409824. We eagerly anticipate serving your needs.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

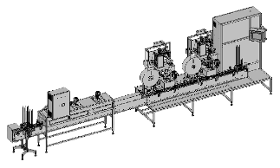

The basic concept of this system is to label form bottles on both sides without using format parts. The adaptation to the respective product takes place by simple adjustment of the machine components. The associated advantages are short set-up times, high availability and multiple use in different production lines. For a high placement accuracy of the labels, the products are precisely aligned on the transport path. Label formats up to 250mm height and cycle rates up to 250 labels per minute are possible. This makes it easy to cover a wide range of products. FM | Form bottles one- oder two-sided | up to 250 products/min FM-DS | Form bottles und cylindrical products (rotating station) | up to 60 products/min FM-RB | Form bottles und cylindrical products (rotation belt) | up to 250 products/min FM-DSRB | Form bottles und cylindrical products | up to250 products/min | (combination of rotating station und rotation belt)

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Labelling machine for wrap-around labelling Basic concept of the system for bottle labelling and can labelling: With the aid of the fully automatic VRM labeller, different cylindrical or square products can be labelled quickly and precisely on the circumference - wrap-around labelling. The machine is therefore used in many industries, from pharmaceuticals to food and cosmetics. The VRM series is suitable for bottle labelling, can labelling, vial labelling or for comparable containers such as jars or bottles. Several different formats can be covered simultaneously with one model. The VRM-DS labelling system includes a 3-roll turning station and is used for outputs of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the containers on the basis of a weld seam, print mark or other feature before labelling (target labelling).

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Continuous rotary blowing machine 6 heads diving filling nozzles Star sterilizing capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. One side labeling machine with coding, dating system Our machine can handle a large type of label, Bottles, and caps Types, size and shapes. SPECIFICATION Pneumatic paddle Volumetric filling system Type of metal used S.S 316 Labeling head. Pneumatic capping gun Drawer feeding caps Label coding system Mechanical weight adjustment system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION One bottles feeding turning table One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Star; sterilizer, filling, capping, closing system. 1 head Diving filling nozzles One side labeling machine. 1 peristaltic pump. 2 dropper and caps feeding system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 diving filling nozzles Star capping and closing system Labeling machine 1 head HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 heads diving filling nozzles Star capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. Our machine can handle a large type of vial bottles , types and shapes SPECIFICATION Machine is made up to the international GMP regulations Turn table feeding system Type of metal used S.S 316 Double Sterilizing nozzles system before and after filling. 2 diving filling nozzles 2 Peristaltic pumps Double star filling and capping system Double caps vibrator feeding system 1 Rubber vial stopper mushroom, 2 aluminum flip caps Rotary capping servo system Delaying bottles conveyor system Herma labeling head HMI and SCADA system with interactive touch screen control system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q , O.Q , P.Q, DQ.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aligner station is a solution if you have to feed glasses, bottles or tins aligned into a filling or labelling machine. By using high-performance product identification up to 350 products/min. can be identified and aligned in a continuous flow of materials. New products can easily be saved with the electrical control system's user-friendly operator interface. Technical data: —Conveyor performance: up to 350 items/min. —Installation length: 1500 mm (identification and alignment) —Infinitely variable adjustment to product height and width Optional equipment: —Camera housing against the influence of other light —High-speed camera for precise alignment even at high conveyor performance —Automatic discharging of faulty products

Request for a quote

TAMPOPRINT GMBH

Germany

Without the pad printing process, the production of everyday objects such as decorated light alloy wheels, or even vital items such as insulin pens would not be easily possible. In doing so, TAMPOPRINT develops and works on process printing solutions across industry boundaries. Thus, there is no such thing as the typical TAMPOPRINT customer or the typical application. Rather, the fields of application are characterized by their diversity, their complexity and their individual characteristics. They range from the simpler printing of toys such as model trains, to the labeling of household appliances and beverage bottles, to highly complex processes such as the micrometer-accurate labeling of medical products, e.g. insulin pens and laboratory tubes. Even the particularly challenging direct application of active pharmaceutical ingredients onto a carrier material, such as in nicotine patches, can be implemented thanks to the TAMPOPRINT solutions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DSMART GMBH

Germany

Production Process of shrink sleeve labels A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Slitting or folding F: Shrink sleeve making/cutting G: Final inspection H: Delivery Other information of shrink sleeve labels A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quote

HERMA GMBH

Germany

Fast, precise, compact High-performance rotary applicator for labeling bottled water, food and personal care products etc. Powerful HERMA 500 applicator with its top speed of 200 m/min and integrated control with convenient adjustment of all parameters via the integrated touchscreen. Automatic speed synchronization. Compact design for up to six applicators per station. Adjustable height and inclination angle. Internal and external low-label and end-of-reel checks. Built-in control and interfaces for integration in higher-level controls.

Request for a quote

HERMA GMBH

Germany

HERMAexquisite changes the whole look of a wine bottle, lending it a more modern character. With sophistication and finesse, HERMAexquisite adds the crowning touch to the perfect symphony of the senses created by taste, bouquet, and image. Adhesive HERMAexquisite 62W 62W is based on an exclusive technical solution and was specially developed for use on wine bottles. It is resistant to damp, ensuring that the label sticks firmly to the bottle even after a lengthy period in an ice bucket. Moreover, this adhesive has ISEGA certification for direct contact with foodstuffs, meaning that it is safe to use with all foods.

Request for a quote

OPTIMA PHARMA GMBH

Germany

Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

DEMAREIS GMBH

Germany

With label panel, as a shaking bottle or in a cylindrical design - it’s up to you what you want to use our bottles for. We have the right design for any purpose. From 3 ml until 1.100 ml

Request for a quote

WHITESTEEL GMBH

Germany

- Compact design - Made up to the ISO, FDA and EU, GMP and cGMP international standards - Can handle multiple cups shapes and sizes - SCADA system included - Touch screen included - Capacity is adjustable up to your needs - Can be used For all liquid substance including alcohol, sanitizers, hand gel, and more

Request for a quoteResults for

Labels for bottles - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Food industry - machinery and equipment (6)

- Labelling machines (4)

- Oils and resinoids (3)

- Food supplements (2)

- Bottling and filling - machinery and equipment (1)

- Labels - stationery (1)

- Custom packaging (1)

- Automation - systems and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Coatings, putties and sealing products (1)

- Conveyor belts (1)

- Pad printing (1)

- Pharmaceutical industry - machinery and equipment (1)