- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- knurled nuts

Results for

Knurled nuts - Import export

HONSEL-GROUP

Germany

The knurled shaft of the blind rivet nut provides a locking device to avoid the turning of the insert in the component. These knurled blind rivet nuts are used preferably in components with lower regidity (component material is less "hard" than the material of the blind rivet nut).They are available with different heads (dome, countersunk and small countersunk) and as open and closed end versions.

Request for a quote

JÄGER & FRESE GMBH

Germany

knurled nut made of stainless steel made by turning M8x15

Request for a quote

JÄGER & FRESE GMBH

Germany

height adjuster with assembled nut we can fit our height adjuster with several types of nuts like knurled nuts or knock-in nuts

Request for a quote

JÄGER & FRESE GMBH

Germany

connecting screw M6 sleeve nut with knurled shaft

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JÄGER & FRESE GMBH

Germany

knock-in nut M10x20 knurled shaft made by turning

Request for a quote

JÄGER & FRESE GMBH

Germany

knock-in nut M10x15 knurled shaft made by turning

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Working range Blind rivet nuts from M3* up to M6 alu and up to M5 steel, brass and stainless steel Technical data Weight: 600 g Total length: 260 mm Stroke: 7 mm Accessories Standard: Threaded mandrel and nosepiece M5 (optional also with M4 or M6) Maintenance instructions with spare parts list Stroke table Features • Simple lift setting via a knurled nut for safe and complete setting of the blind rivet nuts • Threaded mandrel protection via spring ring for fast tool-free replacement of the threaded mandrel • With opening spring for simple handling • Body in high-quality die cast aluminium • Body head made of forged chrome-vanadium steel • Ergonomic handles

Request for a quote

EM-TECHNIK GMBH

Germany

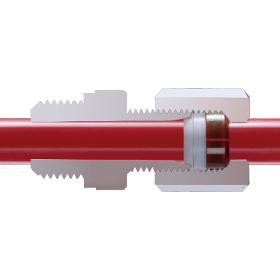

The firm flexible tube or plastic pipe is pushed onto the integrated connecting sleeve of the 1C connector. The sealing ring forms a tightness for the connection, while it is secured in place by a cutting ring. Due to the knurled nut, this also affects the flexible tube. The cutting ring wedges into the flexible tube or pipe as far as the knurled nut is screwed onto the connector body. A shear force is applied here that intensifies the contact pressure. This creates a friction-locked and tight connection that can be released at any time and minimises the dead volume.

Request for a quote

EM-TECHNIK GMBH

Germany

The flexible tube for the connector 1D is first thermally widened and then pushed on the integrated connecting sleeve. The tube is secured in place by means of a knurled nut acting on the flexible tube. Thanks to the form-fit connection between the connecting sleeve and flexible tube, the connector has no dead volume.

Request for a quote

EM-TECHNIK GMBH

Germany

The flexible tube is widened when it is pushed onto the integrated connecting sleeve of the 1B flexible tube connector. The tube is secured in place by means of a knurled nut acting on the flexible tube and the connecting sleeve. The connector permanently has a pressure stage of PN 10. Easily able to withstand a brief pressure peaks of up to 30 bar at T= 20°C.

Request for a quote

EM-TECHNIK GMBH

Germany

The flexible tube is pushed onto the integrated connecting sleeve of the 1A flexible tube con-nector. By tightening the knurled nut, the clamping ring presses against the flexible tube and fixes it in place. The connecting sleeve for the flexible tube is nearly cylindrical. Its dimensions are calculated to prevent tube strain over 6%, even with poor tolerances. The tension produced by the low tube strain is sufficient by itself to guarantee a tight flexible tube connection up to 6 bar. The clamping ring and knurled nut secure the connection against longitudinal forces which could otherwise pull the flexible tube off the connecting sleeve. The clamping ring is designed to secure the flexible tube in place by intercepting any shear or tor-sional stresses. This allows for usage up to 10 bar*. Thanks to its elasticity, the clamping ring can be used several times in the same connector.

Request for a quote

EM-TECHNIK GMBH

Germany

The pipe or tube of the 2D pipe connector is inserted through the connector as required for bead tubes, immersion tubes, thermometers or sensors, etc. The pipe is placed against the inner edge of the connector and a sealing ring seals off the connection. A cutting ring wedges into the flexible tube or pipe as far as the knurled nut is screwed onto the connector body, thereby fixing the connection in place.

Request for a quote

EM-TECHNIK GMBH

Germany

The 1M micro connector was developed especially for medical, pharmaceutical and analytical technology. It provides ideal connection features for PFA, silicon or Tygon® flexible tubes. The micro connector consists of a connector body with integrated conical connecting sleeve, a knurled nut for fixing the flexible tube and a slotted pressure ring. The pressure ring can be omitted for PFA flexible tubes.

Request for a quote

EM-TECHNIK GMBH

Germany

For the 2N pipe connector, the pipe is placed against the inner edge of the connector and a sealing ring seals off the connection. A cutting ring wedges into the flexible tube or pipe as far as the knurled nut is screwed onto the connector body, thereby fixing the connection in place. This creates a friction-locked and tight pipe connection that can be released at any time, that eliminates dead volume in the design concept and also has no effect on the flow. The inside diameter of the connector does not correspond to the inside diameter of the pipe.

Request for a quoteResults for

Knurled nuts - Import exportNumber of results

16 ProductsCountries

Company type