- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- knife cut

Results for

Knife cut - Import export

BRUNO UNGER GMBH & CO KG

Germany

For punching film or plastic packaging, manufactured according to customer requirements

Request for a quote

WESTMARK GMBH

Germany

• cutting knife principle • with cap lifter in the handle • hardened knife and transport wheel

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

Whether cutting, sawing or perforating tooth, for all printing machines and grammages. Manufactured from conventional steel strips to high-alloy and powder metallurgical steels.

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

Cutting- and perforating of foil- and plastic webs

Request for a quote

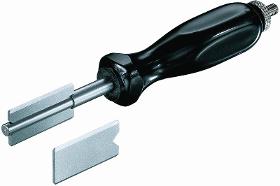

CARL FRIEDRICH USBECK KG

Germany

plastic handle*interchangeable blade*made from hard metal*length 185 mm

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

Robust and durable As a naturally renewable raw material, wood is not only one of our favourite building materials, it can also be disposed of and recycled with comparative ease. For old wood recycling, tables, kitchens, damaged railway sleepers or chipboard are recycled using singleshaft shredders. In these machines, our cutting crowns and knife holders in a very wide variety of sizes and versions have been used for many years and have proven themselves in practice day after day.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Available in different sizes and for film webs from 310 mm to 610 mm. Optionally with roller knife cut for soft blisters or die-cutting tool for hard blisters. Additional equipment options for online printing, vacuum, MAP, automatic loading system and much more.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 34 x 46 cm age 2000 DDS film dampenings single sheet feeder laser cut ink knife central size adjustment dry sprayer max. 10.000 sheets / h (off-load) shown totalizer: approx. 23 mill. impressions Delivery time: immediately Ref: HE220302A Please ask for price. We ship and install worldwide!

Request for a quote

SPANSET SECUTEX GMBH

Germany

The protection against „sharp edges“ Alongside other factors such as temperature, chemical environment and mechanical loads, the „sharp edge“ remains one of the main causes of damage to the lifting accessory itself and frequent cause of accidents. Most damage on sharp or rough edges is the result of load movement perpendicular to the load lifting accessory. If the edge is „sharp“ it can, in a worstcase scenario, cut through the lifting accessory. If the load moves laterally, a cutting movement takes place at the edge. Much like the blade of a knife, the edge can cut through the fibres of the textile lifting accessory. For loads with a „sharp edge“ or with a rough surface, a protective sleeve or fixed coating is recommended to protect the textile lifting strap.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 32 x 46 cm age 1983 single sheet feeder Varn Kompac film dampening laser cut ink knife quick plate clamping bar dry sprayer + version numbering unit N+P shown totalizer: approx. 37 mill. impressions Delivery time: immediately from stock Ref: HE230330A Please ask for price. We ship and install worldwide!

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

max. size 36 x 52 cm age 1996 single sheet feeder photoelectron. double sheet control DDS film dampenings laser cut ink knifes quick plate clamping bar register system Bacher 425 mm dry sprayer Weko + version shown totalizer: approx. 27 mill. impressions Ref: HE240193A Please ask for price. We ship and install worldwide!

Request for a quote

SPANSET SECUTEX GMBH

Germany

secutex has developed the new “TopDrain” structure surface for lifting wet or oily components. Most of the damages at sharp or rough edges are caused by the movement of the load across the sling. In the case of loads with a “sharp edge” or with a very rough surface, a protective sleeve or fixed coating must be used to protect the textile lifting sling. If the load moves sideways, a cutting movement on the edge is the result. Similar to a knife blade, the edge can cut through the fibers of the textile sling. The new “TopDrain” surface drainage provides good adhesion of the protective sleeves and the coated lifting slings even on wet and oily materials. The liquid can drain off into the surface hollows and the load lies securely in the lifting sling. The “TopDrain” structure works like a drainage and ensures the frictional connection of the secutex coating to the load.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The travelling circular knife machine CCM 6 cuts rigid profiles and tubes accurately to length. The CCM 6 achieves very long processing times of several seconds for excellent "final trim quality" thanks to a standard servo linear drive for the tool carrier, and at the same time extremely short cycle times of less than one second for machining short parts at high line speeds. Added to this is the servo linear drive for circular knife feed with different feed speeds for different material sections, e.g. a gentle material penetration or knife exit with low feed to reduce burr formation. High speed ranges As far as the knife speed is concerned, we offer you outstanding possibilities of alternatively 2,000 – 6,000 rpm or 4,000 – 12,000 rpm. This means that there are no limits to the use of various types of circular knives, including clamping and grinding in continuous operation. Our product videos will give you an insight into the machining process.

Request for a quote

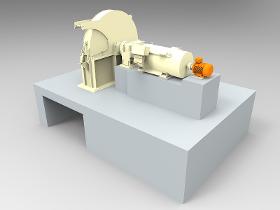

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with lling level control, to a subsequent conveyor. Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Features, Function Chip length 20-25 mm Chip width 4-10 mm Options Adjusting devices for rotor and stator Knives

Request for a quote

WESTMARK GMBH

Germany

• for commercial use • designed for cans in catering size • cutting-knife-principle • knife and traction wheel specially hardened and tin-plated

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Disc chippers are especially suitable for processing straightly grown round wood into high quality wood chips. The raw material is fed into the chipper via a slanted horizontal feeding conveyor. The disc inside the housing is equipped with knives. The logs are processed to chips between the vertical rotor knives and the counter knives. The chips are discharged below via a discharge chute, with filling level control, to a subsequent conveyor. Features, Function Chip length 20-25 mm Chip width 4-10 mm Chipping disc with large flywheel effect Robust, double-sided disc bearing Electro-mechanical locking during knife change Quick knife changes Re-grindable knives Advantages High, consistent chip quality Quick, ergonomic knife changes Cutting force supports material infeed Options Adjusting devices for rotor and stator knives

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing Main shaft drive frequency-controlled three-phase drive Paper cutting knife Film removal control Product insertion control intermittent product delivery clocked forehead sealing frameless protective doors made of 15mm Makrolon PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing rotary foil wrapping head Main shaft drive frequency-controlled three-phase drive Rotary shear cut knife Film removal control Product insertion control continuous product transport through the folding switches continuously working forehead sealing quick format adjustment Protective doors made from Makrolon, relieved of gas pressure springs PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quoteResults for

Knife cut - Import exportNumber of results

21 ProductsCountries

Category

- Offset printing machinery (3)

- Blades and knives, industrial (2)

- Crate packing machinery (2)

- Straps, woven - industrial (2)

- Tin openers (2)

- Custom packaging (1)

- Flexible packing (1)

- Laboratory equipment and instruments (1)

- Mechanical engineering - custom work (1)

- Pipes and tubes - ferrous metal (1)

- Steels and metals - forming and cutting (1)

- Wood veneer - machinery and equipment (1)