- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shears

Results for

Shears - Import export

HONSEL-GROUP

Germany

The FERO-BULB series are used in large quantities in various industrial appliances for a long ti me. Particularly in the field of vehicle and tank construction, this type of rivet is an excellent choice. FERO-BULB blind rivets feature the following characteristics: — very high shear strength through a captive mandrel — large setting head which folds during the setting process — captive mandrel locks vibration proof inside the rivet — dust proof and splash waterproof — high clamping force onto components

Request for a quote

HONSEL-GROUP

Germany

FERO-BOLT high-strength blind rivets are first-class fasteners for industrial applications, especially in those with the attension to the safety factor. Due to its special construction method, this rivet is able to take over load-bearing functions. Typical is the guaranteed flush break with the setting head. Advantages: — very high shear strength with captive mandrel that absorbs parts of the forces — large grip ranges — visually checkable interlocking of the mandrel — vibration resistant — splash waterproof — very good capability of filling the bore hole

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The linear manipulation system is perfectly suited for detaching complex structures, such as windows, manholes, cut-thoughs and circular sections. With its high flexibility, it can easily adapt to conditions on-site. The simple assembly operation is performed by means of tensioning belts. The system’s adaptation to the internal diameter is possible.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Device for remote controlled handling of a cutting nozzle by WAS cutting, suitable for cutting of two-dimensional outlines. This cutting table has been designed for two-dimensional contours. One of its major plus points is its extremely low weight with the associated ease of handling and mobility.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The chain manipulation system is the system of choice for rotationally symmetrical geometries, especially pipes. The chain enables flexible application on external diameters between 400 and 1500 mm.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Mobile water jet cutting unit particularly suited for Defusing large-caliber fund munitions EOD (Explosive Ordnance Disposal) & IEDD (Improvised Explosive Device Disposal). Environmental exposure over the time has chemical and/or physical effects on ammunition & often leads to a critical in-situ situation of the UXO. Conventional Render Safe Procedure (RSP) is very often not feasible without contacting or shifting the UXO and therefore is considered as not secure. In such situations repeatedly it came to severe accidents with death tolls. Hence safety of transport to carry-off for final removal is also not given.Therefore in such cases blasting the UXO is so far used as a final RSP causing partly heavy collateral damages. This unit allows to remove or deactivate the fuse remotely, risk-free & safe by using the WAS Technology & specially designed manipulation systems. The deployment of this technology around the globe has become state of the art today and is an accepted RSP world-wide

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Facing new manufacturing challenges? Want to be quicker and more precise than your competitors? Then you need ConSus. The ConSus system is an Abrasive Mixing Unit (AMU) in which abrasive is added continuously to the pressurized water flow with the worldwide patented lock method. High capacity and low pressure have been unachievable in water jet cutting until now. That’s exactly what the Water Abrasive Suspension (WAS) cutting method from ANT delivers. Tests prove: The ANT suspension jet cuts two to three times faster than conventional water jet cutting methods and at less than half the pressure. The reason for this is the composition of the water jet - a suspension made of water and an abrasive, which is pressurised without air before being squeezed out of the nozzle. The omission of air allows the jet to cut much more efficiently. ConSus combines all of these benefits in a single unit, which can be integrated into any existing water jet cutting system.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

AMU - Abrasive Mixing Units higher 700 bar. The AMU series was standardised for various industrial application ranges. Amongst these are the decommissioning and maintenance of offshore structures and plant in the petrochemical and nuclear technology industries. Also special applications, in the wind power industry or for structural or civil engineering are not uncommon. The unit designation always refers to the maximum working pressure and the gross capacity of the pressure vessel. In combination with a conventional high-pressure pump, the various pressure levels and nozzle diameters can be individually adjusted to the task in hand. Our cutting devices and equipment help to control the cutting processes with our water jet cutting systems (AMU higher 700 bar) from a large distance.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

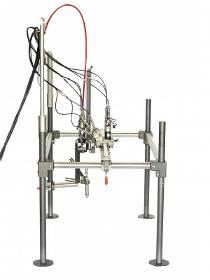

Device for remote controlled handling of a cutting nozzle by Water Abrasive Suspension cutting, suitable for cutting of three-dimensional outlines.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The base fuse manipulator was developed for cutting SAP, MC, GP and AP bombs. After it is applied to the base of the bomb, the water abrasive jet cuts out the detonator. Alternatively, the manipulator can be configured to cut away the entire bomb base together with the detonator.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The hydraulic system of the MACE served the control of the cutting axis at the manipulation systems of the Water Abrasive Suspension (WAS) cutting unit MACE. For guaranteeing the safety distance - up to 500 meter - a control panel is included for the operator which controls the motion axis and the cutting speed.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The DW292 is specifically designed for cutting monocrystalline silicon ingots up to 300mm diameter into high quality wafers for the semiconductor industry. The newly developed DW292-300 can be operated with slurry wire, as well as with diamond wire, and has sophisticated features for optimizing warp and ripple. The longer wire field, as well as the higher wire speed and acceleration, enable a higher throughput per machine and year. The use of extremely thin wire is possible thanks to smaller inertia of moving parts, fewer deflection rollers and shorter wire distance. The DW292-300 is highly resistant to temperature fluctuations and vibrations due to its compact and robust machine frame made of mineral casting. Thanks to higher process automation and the new intuitive HMI with dialog-based production wizard, operation is safer, easier and faster.

Request for a quoteResults for

Shears - Import exportNumber of results

14 ProductsCountries

Company type