- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cuts

Results for

Cuts - Import export

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The linear manipulation system is perfectly suited for detaching complex structures, such as windows, manholes, cut-thoughs and circular sections. With its high flexibility, it can easily adapt to conditions on-site. The simple assembly operation is performed by means of tensioning belts. The system’s adaptation to the internal diameter is possible.

Request for a quote

LALK GMBH &CO. KG

Germany

The Elite Cut S 85 is an ideal choice for applications involving abrasive materials and asphalt, thanks to the grooves in the segments that efficiently cool the blade and discharge abrasive debris. With optimized 12mm tall segments, its special shape and composition ensure long life and consistent performance.

Request for a quote

LALK GMBH &CO. KG

Germany

The Tacti Cut S 50 allows for fast cuts in standard building materials like concrete, brick, and masonry, making it versatile for a wide range of applications. A good value for its high output power. Safety and stability are ensured, as the blade was developed and manufactured in compliance with the EN13236 standard and the ISO 9001 quality standard.

Request for a quote

LALK GMBH &CO. KG

Germany

Further developed diamond cutting disc to cut today's materials even faster & better. The cutting disc masters porcelain stoneware up to 2 cm thick, all types of natural stone and tiles with ease. The high cutting speed and the very clean cut are convincing in everyday use and make this tool with its very long service life a perfect companion on the construction site.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The chain manipulation system is the system of choice for rotationally symmetrical geometries, especially pipes. The chain enables flexible application on external diameters between 400 and 1500 mm.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The hydraulic system of the MACE served the control of the cutting axis at the manipulation systems of the Water Abrasive Suspension (WAS) cutting unit MACE. For guaranteeing the safety distance - up to 500 meter - a control panel is included for the operator which controls the motion axis and the cutting speed.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

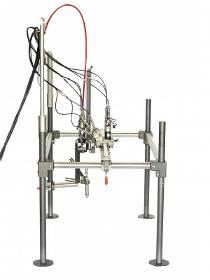

Device for remote controlled handling of a cutting nozzle by WAS cutting, suitable for cutting of two-dimensional outlines. This cutting table has been designed for two-dimensional contours. One of its major plus points is its extremely low weight with the associated ease of handling and mobility.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

For the abandonment of Offshore structures special legal requirements apply. Tubes have to be deconstructed under the seabed. This requires special technologies. Our Downhole Cutting Heads (DCHs) can be inserted into tubes and casings over an umbilical from the working platform. Arriving at the destination they clamp in the tubes and perform a 360 degrees cut which severs the tube underneath the seabed. The DCH is pulled out and afterwards the pulling of the tube is possible. Cuttings can be performed up to 150 m (500 ft) deep and pipe sizes between 7” and 72” diameter, whereby the wall thickness can be up to 20” thick. For every requirement we offer the appropriate DCH. By extensions nearly every kind of pipe/tubing/casing can be cut.

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

Device for remote controlled handling of a cutting nozzle by Water Abrasive Suspension cutting, suitable for cutting of three-dimensional outlines.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

SpeedCore is a newly developed substrate for hobs. The increased hot hardness of the intermetallic cutting material allows for cutting speeds of at least 30 % higher compared with HSSPM4/ 14 hobs, resulting in shorter production times without sacrificing tool live and ocmplies with the demand of customers for easy handling and easier recycling. Combining the new SpeedCore substrate with a custom coating achieves top performance with easy implementation and high reliability. Advantages - Improved productivity of up to 70 % - Process reliability (like HSS-PM) - Easy to implement; also on older or unstable machines - Regrinding and coating possible without problems

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

AMU - Abrasive Mixing Units higher 700 bar. The AMU series was standardised for various industrial application ranges. Amongst these are the decommissioning and maintenance of offshore structures and plant in the petrochemical and nuclear technology industries. Also special applications, in the wind power industry or for structural or civil engineering are not uncommon. The unit designation always refers to the maximum working pressure and the gross capacity of the pressure vessel. In combination with a conventional high-pressure pump, the various pressure levels and nozzle diameters can be individually adjusted to the task in hand. Our cutting devices and equipment help to control the cutting processes with our water jet cutting systems (AMU higher 700 bar) from a large distance.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

Carbideline consists of CarbideLine-S solid carbide tools, CarbideLine-H hybrid tools and multi-part carbide tooling with CarbideLine-I indexable carbide tools. All CarbideLine tools excel through maximum productivity in their specific fields of application. CarbideLine-H tools are a new addition to the product range. They cover the module range 5 to 12 and are the 1st. choice for rough machining and finishing large lot sizes, where the tools costs using solid carbide milling cutters are too high and the gear cutting quality is too low using indexable inserts. CarbideLine-H tools are also highly suitable for machining high-strength materials up to 1,400 N/mm2 and enable a gear quality up to quality grade AAA. Its preferred area of application is for gears for commercial vehicles, general mechanical engineering and energy technology. In one specific application it was possible to reduce the gearing costs per wheel by 20% with the CarbideLine-H compared with an indexable insert system.

Request for a quoteResults for

Cuts - Import exportNumber of results

14 ProductsCountries

Company type