- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- it solution

Results for

It solution - Import export

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

Since 1934 working with elastomers, we have developed special know-how in development and manufacturing in the field of technical hose products. Hoses Hose systems Moulded articles Rubber-metal bonds Expansion joints Special Versions As individual components or as combinations. Here, our experts unleash their creative powers and problem-solving skills. The main features of these customer-specific versions are top quality and high degrees of innovation and individualisation, directly maximizing the benefits to the customer. The following pages give some insight into the wide range of technical hose products and possible solutions to problems. Please do not hesitate to contact our technical sales department for more information.

Request for a quote

ASP GERMANY

Germany

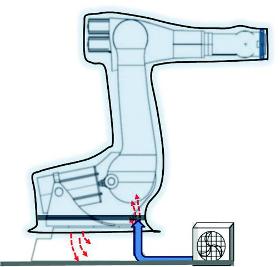

The fan provides a permanent air circulation that keeps the robot dry. The volume of air is renewed preventing moisture from condensing inside the cover.

Request for a quote

ASP GERMANY

Germany

ASP’s «ATEX» solutions are made from specific materials and fabricated in compliance with ATEX directive 2014/34/EU. The ground braiding ensures that the cover remains electrically neutral. The «Custom» Design offers maximum efficiency while complying with your constraints and requirements and without restricting robot movement. The ventilation/pressurization option optimizes protection performance. Covers repaired in our workshops provide resilient and long-lasting protection for your robots.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Smooth final assembly The many different processes included in final assembly require precisely timed provision of parts and ergonomic support for manual work. Your advantages using Lödige solutions during final assembly Ergonomic work platforms Connection to high-bay warehousing Efficient preparation of different assemblies Linked materials handling systems Quick access to assemblies in intermediate storage Automation

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Fully automated storage In the automotive industry, storage in high-bay warehousing and precise, sequential provision are a vital part of the production process. Your advantages using Lödige solutions for efficient storage and order picking Custom-made racking systems Optimum use of space Storage for every sort of component Connection to internal materials handling systems Storage, materials handling and control technology — all from one source Quick and safe storage

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Quality at every level Safe transport and short throughput times — Lödige‘s material handling solutions easily accommodate all the demands made on them whether within the paint shop or in provision and intermediate storage after the painting process. Your advantages using Lödige solutions in the paint shop: Materials handling in multiple dimensions Connection to intermediate store Connection to body shell store Work stations Internal and external materials handling systems Materials handling systems and control technology from one source

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Safe and powerful For an efficient body shell process, the correct bodywork components must be reliably brought from their intermediate storage areas and production lines to be assembled. Lödige’s materials handling and control solutions automate this procedure. Your advantages using Lödige solutions in the body shop: Connection to the pressed component store Conveying on several levels possible Connection to bodywork store Horizontal materials handling systems High levels of automation possible Control connection to robotic systems

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Profitable turn-key systems Accuracy, reliability and throughput are essential for the success of any material handling in industrial processes. Lödige Industries provides integrated solutions for an efficient material flow from goods-in, through the production process and goods-out, including tracking and stock control functions throughout. We plan, install and commission these solutions and provide an effective life-cycle service support to strengthen your competitive edge. Working closely with our customers we plan, simulate and implement conveyor solutions and turn them into profitable turn-key systems. Thanks to our industry-specific expertise, we optimise your material flow operations, increase the performance of your system and help to reduce operating costs significantly. We are unique in providing the complete solution with in house expertise: System analysis, planning, design, manufacture and supply of material handling systems, management software, installation, commissi

Request for a quote

SITEMA GMBH & CO KG

Germany

In particular applications, it can be necessary to hold high axial forces and torque at the same time. For pneumatic operation, our Locking Unit series KFPD meets this demand. Depending in the size, forces / torques of 12 kN / 120 Nm or 30 kN / 500 Nm can be held securely. The “normal” SITEMA Locking Units KFH are already able to hold smaller torque. Example: 280 Nm with, at the same time, an axial holding force of 100 kN on rod diameter 56. In case higher torque needs to be held, SITEMA’s special design series KFHD can help. With this design, it is possible to hold torque with a factor of 10 higher compared to the standard KFH unit. Example: 2800 Nm with, at the same time, an axial holding force of 100 kN on rod diameter 56. Whether the operation is pneumatic or hydraulic, the application is limited to static holding. The KFPD and KFHD can prevent a rotation from starting, but are not suitable to brake rotating masses.

Request for a quote

SITEMA GMBH & CO KG

Germany

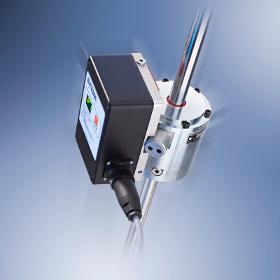

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

SITEMA GMBH & CO KG

Germany

KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Safety Catcher The Mechanical Safety Catcher KRM is operated purely mechanically and requires neither a hydraulic nor a pneumatic system for control. The clamping head is kept open mechanically and acts upon rupture of the suspension (rope, belt, chain, etc.). The energy of the falling mass is then used to generate the clamping force. In applications where lifted loads can be dangerous in case of rupture of the suspension device, Safety Catchers KRM are used to protect people and assure accident prevention. Safety Catchers KRM secure the load at any point of the stroke in a mechanically safe and absolutely reliable way. Due to the principle of self-reinforcing clamping, a very high level of safety is reached. Application example Packing...

Request for a quote

SITEMA GMBH & CO KG

Germany

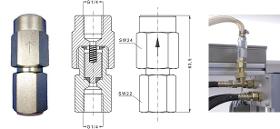

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

SITEMA GMBH & CO KG

Germany

More space to work – let the rods out! In particular applications, it can be necessary that the rod leaves the clamping head, e.g. for reasons of accessibility or restrictions regarding space that do not allow a rod that is permanently in place. Especially in applications where moulds are closed and kept closed against high forces with the SITEMA PowerStroke, it is a big advantage when the rod can leave the clamping head. Thus, the rods are no obstacle when taking finished parts out of the mould or when handling parts. With certain modifications, most of our series can be adapted as special designs to allow the rod leaving and re-entering the clamping head. We have already realised a great number of such solutions for vertical and horizontal applications. Contact us for more information!

Request for a quote

SITEMA GMBH & CO KG

Germany

Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Mechanical Valve Actuator MVA Secure the rupture of a chain with the full comfort of a pneumatic SITEMA clamping head When a load has to be secured against rupture of a suspension device (e.g. a chain), many customers use our Mechanical Safety Catcher KRM. This unit has the advantage to hold the load immediately upon rupture of the suspension device. Additional sensors to detect rupture of a chain are not necessary. On the other hand, it is not possible to activate the KRM in a user-defined position without rupture of the suspension device, e.g. for maintenance purposes. Here, the Mechanical Valve Actuator MVA comes to your rescue. It is simply put between the suspension device and the...

Request for a quote

SITEMA GMBH & CO KG

Germany

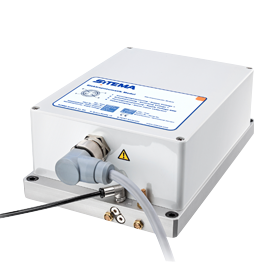

Mechanical Valve Actuator MVA Rod leaving clamping head Auto Bleeder Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electropneumatic module EPM The Electropneumatic Module EPM acts as interface between (electrical) power supply / control and a pneumatic SITEMA clamping head. All pneumatic SITEMA clamping heads with an operating pressure of up to 4 bar and an operating volume of up to 220 cm³ can be pneumatically controlled by the EPM. It is also possible to operate several clamping heads in parallel with one EPM. The EPM is controlled by a 24V supply and switching voltage. The outlet pressure which is required to open or keep open a pneumatic clamping head is controlled by a control signal. If the voltage fails or the input signal is switched off, the pressure is...

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

Hugo Beck can claim a decade-long development tradition when it comes to automation. We offer support with our expertise throughout the entire automation process, from project planning and manufacture right through to integration into complex packaging lines. Handling systems such as portals, grouping solutions, stacking and counting devices, cross pusher to name but a few, are integrated reliably into the packaging solutions by our technicians. Furthermore, various robots systems are used across many industries for the automated feeding of products, helping to for example grip, position, stack, group, stage products. From a parallel robot (also known as a spider robot) all the way through to a SCARA robot – anything is flexibly possible and delivered fully integrated according to each customer‘s needs. Both robots and handling systems can all be purchased independently of Hugo Beck packaging machines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER SCHMIDT CHEMIE GMBH

Germany

It is particularly pure and enables clean and low-soot combustion. Other sizes available on request

Request for a quote

WALTER SCHMIDT CHEMIE GMBH

Germany

AdBlue® - the additional fuel that reduces the emission of nitrogen oxides (NOx) in diesel engines by up to 80%. For diesel vehicles with AdBlue tank (SCR catalytic converter). Other sizes available on request

Request for a quote

MICRO-EPSILON

Germany

Gauges and inspection systems from Micro-Epsilon are used in the plastics processing industry in order to ensure efficient production.

Request for a quote

MICRO-EPSILON

Germany

The rubber processing industry, as well as the tire production process is supported by Micro-Epsilon with a range of systems for inspection, monitoring and control of miscellaneous processes.

Request for a quote

MICRO-EPSILON

Germany

In addition to pure color measurements, intensity measurements, completeness and presence checks or the evaluation of surface properties are also possible with the color sensors from Micro-Epsilon. These powerful colorSENSOR CFO sensors enable 100% control in demanding, industrial measurement tasks and provide precise measurement results.

Request for a quote

BEFORT WETZLAR OD GMBH

Germany

Based on the longstanding experience in the field of industry optics, Befort is your optimal partner for the new development and production of customer specific optics and mechanooptic systems. Our experts will find and realize the best solution for your optical problem. Solutions may be based on a variety of technologies, such as spherical, refractive optics, but also freeform optics, micro optics, diffractiveaspheric or plastic optics. Furthermore, we integrate electronics, sensor technology, controls and image processing jointly with external partners. OUR SOLUTIONS ARE APPLIED IN A VARIETY OF MARKETS Medical technology Automotive Mechanical engineering Industrial image processing Laser technology Defense Sensor technology

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

The search for solutions in the field of process engineering systems and methods presents us with new challenges every day. Electric heaters for the direct thermal treatment of incoming air in air conditioning systems or as preheater or afterburner for intake air in industrial equipment using intelligent processadapted control systems are gaining an increasing acceptance

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TANKS AND SYSTEM SOLUTIONS FOR SOLID, LIQUID AND GASEOUS SUBSTANCES As a tank construction specialist, we offer quality tanks and system solutions in steel for industry, communities and agriculture. Our unique Lipp System construction method ensures the highest levels of quality when storing solid, liquid and gaseous substances. Your project, from an individual tank to a complete turnkey plant, will be completed with the emphasis firmly on longevity, flexibility and individual adaptability. With over 55 years experience in plant and tank construction, LIPP GmbH is a family company which is active worldwide. We have carried out over 10,000 projects world wide and own over 170 pioneering patents.

Request for a quote

MICRO-EPSILON

Germany

The surfaceCONTROL 3D 2500 snapshot sensor is used in 3D measurements for geometry, shape and surface inspection on diffuse reflecting surfaces. The sensor can be used in both automated in-line and at-line inspections as well as in the metrology room. The fringe light projection allows direct 3D measurement. The sensor is characterized by its large measuring field as well as a high measuring range depth of up to 300 mm with a repeatability of up to 3.0 µm. The captured images are transferred to the external controller where they are processed into 3D data. Three models cover different measuring fields.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp systems are modular and can be extended, modified or integrated into existing systems WITH EASE. Biogas plants from Lipp are based on the so called, wet fermentation. Through a 2 stage process, i.e., via regulation by an upstream hydrolysis stage or other substrate pre treatment, input materials are prepared so that the anaerobic process can run optimally in the digester. Since it is the most flexible and the biological processes are best kept controllable Lipp favours the SBR process. This is also particularly suitable for anaerobic wastewater treatment, sludge digestion and is also used in agricultural biogas deposits. This means first that Lipp biogas plants are substrate flexible and allow an intensive use of the available digester area. Secondly, that with low self sustaining energy requirements, a high degradation rate is achieved. It is interesting to note that Lipp’s digester can be operated not just in the SBR process (Sequence Batch Reactor).

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

BIOGAS FOR INDUSTRY, MUNICIPALITIES AND AGRICULTURE In addition to tank construction, LIPP built the first biogas plant in Germany in the 70’s. Furthermore, LIPP was one of the first companies to develop and sell small biogas plants in the early 80’s. By steady advancements in production technology and the materials used, as well as extensive experience in process engineering LIPP has installed in collaboration with its partners, hundreds of biogas plants in Germany and worldwide. The majority of these projects are still in operation and ensure proof of the high quality and the technical and economic performance of Lipp’s system solutions. LIPP provide system solutions for biogas production in the following areas APPLICATIONS anaerobic wastewater treatment plants waste fermentation plants sewage sludge digestion agricultural biogas plants

Request for a quoteResults for

It solution - Import exportNumber of results

199 ProductsCountries

- Germany (199)

- Berlin and region (24)

- Bonn, Düsseldorf and North Rhine and Westphalia (30)

- Frankfurt am Main and Hesse (14)

- Hamburg and region (1)

- Hannover and Lower Saxony (2)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (3)

- Mainz and Rheinland-Pfalz (6)

- Munich, Nuremberg and Bavaria (27)

- Saarbrücken and Saarland (3)

- Stuttgart, Freiburg and Baden-Wurtemberg (77)

- Weimar and Thuringia (11)

Category

- Cleaning and maintenance products, household (24)

- Tanks, metal (24)

- Labelling machines (15)

- Trolleys and trucks (12)

- Lighting, street, industrial and commercial (10)

- Electronic data processing - microcomputers (8)

- Pad printing (5)

- Sensors (5)

- Switching systems (5)

- Cutting - machine tools (4)

- Machine tools, metal machining - parts and accessories (3)

- Chemicals - Basic Products & Derivatives (3)

- Packing and packaging - machinery and equipment (2)

- Automation - systems and equipment (2)

- Accumulators and batteries (2)

- Keyboards - computer (2)

- Milling - steels and metals (2)

- Printers - computer (2)

- Software (1)

- Customer relations management software CRM (1)