- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- insulated sheet

Results for

Insulated sheet - Import export

TEPROSA GMBH

Germany

Baking varnish is a special joining technology for sheet metal packages. After the individual lamellas have been cut, electrical steel with a baking varnish coating is baked into a sheet metal package in a two-stage temperature step. The result is a full-surface, solid connection between the individual sheets with complete insulation. Sheet metal packages manufactured in this way have high precision and perfect magnetic properties. Advantages of the Backlack process: The Backlack process offers several advantages over alternative packaging processes, which we will discuss in detail below. Precision – Sheets coated with baking varnish are baked over the entire surface. This means that even delicate slats can be assembled precisely.

Request for a quote

PANEL SELL GMBH

Germany

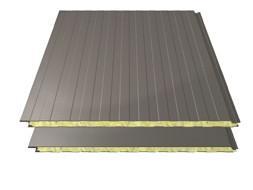

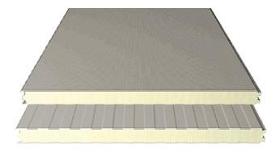

For roof-construction in industry and commerce, Panelsell Ltd are able to provide sheets in various thicknesses and lengths. Increasingly instead of profiled sheets (uninsulated trapezoidal sheets), insulated roof panels are used. These panels consist of an upper and lower sheet, which are usually made of galvanised painted steel. Standard thicknesses tend to between 0.4mm to 1.0mm, which can produce different strengths as needed. It is also possible to have the outer and inner sheets made from aluminium or stainless steel.In areas exposed to a heavy stress due e.g. to ammonia, ECO panels are also used, as an alternative to insulated roof panels with a galvanised inner surface made of steel sheet. The inner surface of these panels is made of stucco embossed aluminium foil. In addition, these roof panels are cheaper than conventional roof panels. Insulation tends to come in both polyurethane and polyisocyanurate (PUR and PIR) as well as rockwool (also known as mineral wool). Decision for the choice of insulation takes into account for flammability and resistance, or structural characteristics such as themal and moisture protection. The roof panels often have a trapezoidal box profile structure. There is an alternative option of corrugated profile (shaped in a sine-wave) and traditional tile aesthetic.. On request, we can offer you the full range of insulated roof panels. This is in accordance to your requred length, thickness and most RAL-colours. Of course, we can also offer special offers and cancelled ordesr that has been returned to site..

Request for a quote

PANEL SELL GMBH

Germany

For roof-construction in industry and commerce, Panelsell Ltd are able to provide sheets in various thicknesses and lengths. Increasingly instead of profiled sheets (uninsulated trapezoidal sheets), insulated roof panels are used. These panels consist of an upper and lower sheet, which are usually made of galvanised painted steel. Standard thicknesses tend to between 0.4mm to 1.0mm, which can produce different strengths as needed. It is also possible to have the outer and inner sheets made from aluminium or stainless steel.In areas exposed to a heavy stress due e.g. to ammonia, ECO panels are also used, as an alternative to insulated roof panels with a galvanised inner surface made of steel sheet. The inner surface of these panels is made of stucco embossed aluminium foil. In addition, these roof panels are cheaper than conventional roof panels. Insulation tends to come in both polyurethane and polyisocyanurate (PUR and PIR) as well as rockwool (also known as mineral wool). Decision for the choice of insulation takes into account for flammability and resistance, or structural characteristics such as themal and moisture protection. The roof panels often have a trapezoidal box profile structure. There is an alternative option of corrugated profile (shaped in a sine-wave) and traditional tile aesthetic.. On request, we can offer you the full range of insulated roof panels. This is in accordance to your requred length, thickness and most RAL-colours. Of course, we can also offer special offers and cancelled ordesr that has been returned to site..

Request for a quote

PANEL SELL GMBH

Germany

For roof-construction in industry and commerce, Panelsell Ltd are able to provide sheets in various thicknesses and lengths. Increasingly instead of profiled sheets (uninsulated trapezoidal sheets), insulated roof panels are used. These panels consist of an upper and lower sheet, which are usually made of galvanised painted steel. Standard thicknesses tend to between 0.4mm to 1.0mm, which can produce different strengths as needed. It is also possible to have the outer and inner sheets made from aluminium or stainless steel.In areas exposed to a heavy stress due e.g. to ammonia, ECO panels are also used, as an alternative to insulated roof panels with a galvanised inner surface made of steel sheet. The inner surface of these panels is made of stucco embossed aluminium foil. In addition, these roof panels are cheaper than conventional roof panels. Insulation tends to come in both polyurethane and polyisocyanurate (PUR and PIR) as well as rockwool (also known as mineral wool). Decision for the choice of insulation takes into account for flammability and resistance, or structural characteristics such as themal and moisture protection. The roof panels often have a trapezoidal box profile structure. There is an alternative option of corrugated profile (shaped in a sine-wave) and traditional tile aesthetic.. On request, we can offer you the full range of insulated roof panels. This is in accordance to your requred length, thickness and most RAL-colours. Of course, we can also offer special offers and cancelled ordesr that has been returned to site..

Request for a quote

PANEL SELL GMBH

Germany

For roof-construction in industry and commerce, Panelsell Ltd are able to provide sheets in various thicknesses and lengths. Increasingly instead of profiled sheets (uninsulated trapezoidal sheets), insulated roof panels are used. These panels consist of an upper and lower sheet, which are usually made of galvanised painted steel. Standard thicknesses tend to between 0.4mm to 1.0mm, which can produce different strengths as needed. It is also possible to have the outer and inner sheets made from aluminium or stainless steel.In areas exposed to a heavy stress due e.g. to ammonia, ECO panels are also used, as an alternative to insulated roof panels with a galvanised inner surface made of steel sheet. The inner surface of these panels is made of stucco embossed aluminium foil. In addition, these roof panels are cheaper than conventional roof panels. Insulation tends to come in both polyurethane and polyisocyanurate (PUR and PIR) as well as rockwool (also known as mineral wool). Decision for the choice of insulation takes into account for flammability and resistance, or structural characteristics such as themal and moisture protection. The roof panels often have a trapezoidal box profile structure. There is an alternative option of corrugated profile (shaped in a sine-wave) and traditional tile aesthetic.. On request, we can offer you the full range of insulated roof panels. This is in accordance to your requred length, thickness and most RAL-colours. Of course, we can also offer special offers and cancelled ordesr that has been returned to site..

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

KAMPMANN GMBH & CO. KG

Germany

Product advantages — for applications with high external pressure — large-dimensioned heat exchanger for maximum possible output — slimline design for installation in suspended ceilings - easy to install XL Outputs This fan coil guarantees XL outputs – even with high air-side pressure loss requirements. The EC fans used can be continuously variably controlled by a 0-10 V DC signal. Well insulated The sheet-steel housing helps to reduce noise and is also insulated against thermal losses, thanks to its integral insulation. Slimline design The Venkon XL fan coil is ideal for installation in suspended ceilings on account of its slimline design. It can be flexible combined with a connection unit for circular ducts to route treated air to targeted ventilation terminal components. Models You have the choice of four models for each application and building of any kind that needs to be cooled and/or heated. Applications Hotels, Offices, Commercial buildings, Restaurants

Request for a quote

POLIFILM GMBH

Germany

These films serve as insulation sheets in the brickwork for the protection against rising damp and moisture. Our masonry insulation films may be laid either directly onto the concrete slab or on the first brick row. Thus, they provide a barrier layer which is insurmountable for the rising damp. The brickwork is optimally protected.

Request for a quote

POLIFILM GMBH

Germany

These films serve as insulation sheets in the brickwork for the protection against rising damp and moisture. Our masonry insulation films may be laid either directly onto the concrete slab or on the first brick row. Thus, they provide a barrier layer which is insurmountable for the rising damp. The brickwork is optimally protected.

Request for a quoteResults for

Insulated sheet - Import exportNumber of results

13 ProductsCountries

Company type