- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- injection parts

Results for

Injection parts - Import export

CIC - KLAUS CZERWONKA

Germany

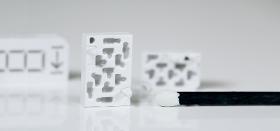

Plastic injection molded parts from all common plastics, prototypes and rapid prototype parts, plastic parts with inserts, plastic parts with paintwork, with chrome plating, with decorative lamination also in leather, rubber parts, rubber-metal connecting parts, parts made of carbon, visible carbon.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Welcome to EWOQE, your specialist for high-precision plastic injection molded parts for medical technology! We understand the demanding requirements of your industry and deliver customized solutions that meet the highest quality standards. Our experienced team collaborates closely with you to develop the optimal plastic injection molded parts for your medical applications. Utilizing state-of-the-art technologies and high-quality materials, we ensure our products comply with the strictest regulatory requirements and offer the highest precision and reliability. Whether for components of medical devices, laboratory equipment, or consumables, we are your trustworthy partner for all your needs in plastic injection molded parts for medical technology. Rely on EWOQE for top-notch quality, rapid delivery times, and excellent customer service. Contact us today to learn more about our tailored solutions for medical technology and to advance your projects.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Testing equipment for quality control and material optimization of die-cast aluminum parts, strength test Quality control of injection molded parts; Predetermined breaking point Hand control robust construction Evaluation via GMV2

Request for a quote

SCHOCK GROUP

Germany

SCHOCK manufactures sophisticated plastic parts for the highest requirements with a modern machinery line consisting of injection molding machines, quick slide machines and multi-component injection molding machines

Request for a quote

KUNSTSTOFFTECHNIK SCHMID GMBH & CO. KG

Germany

To meet the ever-growing demands placed on injection moulded parts and modules, we rely on automated solutions from our proprietary special-purpose engineering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLN ULTRASCHALL AG

Germany

Based on a long tradition of ultrasonic processing KLN Ultraschall AG also today develops and builds edge-welding machines for textile back injection molded parts. Here in very complex fixtures the textile overlap is put around the part and fixed by means of special sliding technology. This is a highly complex task and requires sound experience in construction and optimisation of the assembly. Here the important know-how is the tool design and not the machine technology. After “edge folding” the stretched textile overlap is permanently bonded with the plastic by means of ultrasonic technology or permanently heated elements on the back of the plastic part.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

The APG-process by HÜBERS permits short cycle times thanks to rapid gelation and demoulding with automatic opening and closing of the mould. During the gelling process, fresh material is supplied continuously to the mould under pressure in order to prevent cracks and voids and to compensate for the shrinkage of the material. The mould is held together by the clamping machine. The degassed material is injected into the APG mould directly from the static mixer. Shrinkage compensation is carried out by the HÜBERS metering pumps. One central mixing and metering system can serve several clamping machines. In this case each clamping machine has its own static mixer positioned directly in front of the mould and also has its own shrinkage compensation unit to maintain the pressure. The system is supplied via a ring line which requires no maintenance and is free of sedimentation. In principle the length of this line is insignificant.

Request for a quote

VOELPKER SPEZIALPRODUKTE GMBH

Germany

By the addition to the most different formulations injected parts can be faster ejected. The use in mineral filled, glass fibre reinforced and/or pigmented compounds improves the homogeneity of the filler and/or pigment distribution, reduces damages by friction peaks and leads to an improved surface quality. We recommend to add amounts of 0.3 – 0.5 %.

Request for a quote

VOELPKER SPEZIALPRODUKTE GMBH

Germany

By the addition to the most engineering plastics injected parts can be faster ejected. The use in mineral filled, glass fibre reinforced and/or pigmented compounds improves the homogeneity of the filler and/or pigment distribution, reduces damages by friction peaks and leads to an improved surface quality. We recommend to add amounts of 0.3 – 0.5 %.

Request for a quote

VOELPKER SPEZIALPRODUKTE GMBH

Germany

By the addition to the most different formulations long flow paths can be realized and injected parts can be ejected faster. The use in filled or reinforced compounds improves, for example, the homogeneity of the fibre glass distribution, reduces the polyamide degradation and leads to an improved surface quality. In addition, damages by friction peaks can be avoided in sensitive formulations. We recommend to add amounts of 0.3 – 0.7 %.

Request for a quoteResults for

Injection parts - Import exportNumber of results

11 ProductsCountries

Category

- Additives for plastics industry (3)

- Cutting - steels and metals (1)

- Electric and electronic components - machines for manufacturing (1)

- Measurement and control instruments (1)

- Medical services - specialised (1)

- Ultrasound systems - Processing plastics (1)

- Vehicles - mechanical components and parts (1)