- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industry 4.0

Results for

Industry 4.0 - Import export

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Die Idee und das Ziel von Industrie 4.0 ist es, in Echtzeit alle relevanten Daten innerhalb von Wertschöpfungsprozessen zu gewinnen, um daraus Optimierungen hinsichtlich Kosten, Ressourcenbedarf und Verfügbarkeit abzuleiten. Dies ist möglich, wenn alle an diesem Prozess beteiligten Komponenten vernetzt sind und die notwendige Information für Bewertung und Aktion bereitstellen. Ein wichtiger Faktor sind dabei Sensoren, die Zustände innerhalb von Fertigungsprozessen und Anlagen erfassen und diese an übergeordnete Systeme wie Steuerungen kommunizieren. Die Standardisierung dieser Kommunikation ist außerordentlich sinnvoll. Novotechnik bietet dazu Weg- und Winkelsensoren mit dem herstellerunabhängigen Kommunikationsstandard IO-Link an, welcher die Eigenschaften intelligenter Sensoren voll nutzbar macht. IO-Link kann über Gateways in unterschiedlichste Bussysteme implementiert werden und ermöglicht über intelligente Diagnose- und Parametrierungskonzepte eine deutliche...

Request for a quote

SIKO GMBH

Germany

Magnetic motor feedback systems are proving themselves in numerous applications in linear drive technology, handling systems, circuit board assembly, robotics and in a wide range of automation solutions in the context of Industry 4.0. In all of these areas, the speed and/or position of a drive must be communicated to a main controller in real time. The ultra compact LEC100 and LEC200 sensor duo has been developed by SIKO for these requirements. Repeat accuracy max. ±1 μm. max. resolution 0.2 µm (LD output circuit). Reading distance ≤0.2 mm. Works with MB100/1 magnetic tape. Signal period 1000 μm. Output circuit sin/cos or LD. Function and status display LEDs.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

The iBird® Pro Gold Edition can be networked with a smartphone, tablet or PC via an app! The app is available for Android and iOs devices. It can be connected to three devices at the same time. With a setting force of 20,000 N and the well-proven brushless motor, the iBird® Pro Gold Edition is powerful and fast when setting blind rivets up to Ø 6.4 mm in any material. The optional Autoreverse function additionally shortens the pulling process, ensuring the iBird® Pro is immediately ready for operation. The iBird® Pro Gold Edition is extremely simple to connect thanks to the QR code located on your tool. Simply scan the QR code with the GESIPA® app and the iBird® Pro Gold Edition will automatically connect to your device. The optional setting process assistant from GESIPA® helps operators to adjust the setting process and evaluate riveting processes. More details on delivery limits will be answered in a specific enquiry (details are only exemplary)!

Request for a quote

COGNEX CORPORATION

Germany

DataMan 280 series fixed-mount barcode readers offer fast decoding, easy setup, and valuable Industry 4.0 features, like web browser connectivity and performance monitoring, in a small form factor. DataMan 280 was engineered to better track and trace items throughout manufacturing and logistics supply chains solving a broad range of tough 1D, 2D, and direct part mark (DPM) code applications. DataMan 280 series was designed to be flexible. The modular hardware and software can be configured to solve any barcode reading challenge. Easily decode difficult DPM codes on challenging automotive and medical device surfaces. Read multiple label-based barcodes simultaneously on boxes and pallets, even behind specular wraps. And accurately read user presented codes with a large depth of focus for speedy handling.

Request for a quote

AAAGILER GMBH

Germany

Shopfloor Management 4.0 means digital dashboards / visualisation of relevant KPIs on large flat screens for daily discussion with production staff. Get the latest tools used by the German industry.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine is the optimal solution for mid-sized batch demands at fast throughput times! The E 40 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. For industry 4.0 demands, the E40 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum only deflashing), suitable for special applications only. mid-sized batches > fast throughput times > E40

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small sized computer controlled deflashing machine can be integrated into the production line easily. This saves temporary storage or extra transports and finally corresponding time loss and costs. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. Alternatively the E30 is available with quick-exchange basket system. This basket is compatible to our high-pressure washing machine W30 and furthermore optimally suited for a linear in-line-processing →production →deflashing →washing →termpering, as this charge-baskets may be used compatible for each machine. For industry 4.0 demands, the E30 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine provides maximum economic efficiency at treatment of big batch volumes at high throughput! The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. At any time, this machine is ready for upgrade to automated application, from the automatic loading & deloading of the machine up to a complete full automated feeding & forwarding system. For industry 4.0 demands, the E90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum-only deflashing), suitable for special applications only.

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond D side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

MINEBEA INTEC GMBH

Germany

The Dymond S side shooters offer reliable detection of foreign objects in tall, upright packaging. The compact hygienic design, interfaces and reliable image processing at high speeds allow for efficient integration into automated production processes. Reliable inspection with a high throughput Maximum safety through multi-sided radioscopy opens up new possibilities in product design Seamless integration and installation Quick and easy cleaning thanks to the hygienic design Industry 4.0 ready

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This automatic washing & drying system provides high efficient cleaning of elastomers in through-feed method (on option washing with de-ionized, de-mineralized or ultra-pure water possible). Starting from the loading station, the washing drums are conveyed automatically to each washing station (→ station pre-washing → station rinsing → station high pressure cleaning → station high pressure drying) and are finally conveyed to the unloading station after treatment. The dimensions of this system depend on the drum dimensions desired (perforation from 3 - 15 mm possible by choice). Set as our default, the models WD3, WD5 and WD9 are available with different sizes. For industry 4.0 demands, this system is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. Siliconisation or other coating of elastomers is possible on option.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The innovative recuperation module from CIC acts as an energy-saving valve and control module directly in the pneumatic circuit. Functionality : It is installed directly on the consumer - e.g. on the pneumatic cylinder or in the pneumatic control circuit. The recuperation valve with its integrated control electronics measures and regulates the air consumption and feeds used compressed air back into the working cycle for reuse. Advantages : Reduction of compressed air consumption by up to 80%. Increase in efficiency of the plant. Smart monitoring and diagnostics of the pneumatic system with numerous evaluation options and control in line with Industry 4.0. Detection of leaks and irregularities. Delivery for predictive maintenance data. Avoidance of downtimes. Simple control software and wireless transfer from PC.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine provides high efficiency cleaning of medical and technical elastomers and is construed for big sized batch demands at high throughput. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W90 offers maximum economic efficiency on treatment of big batch volumes at high throughput!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This machine offers high efficiency cleaning of medial & technical elastomers and is construed for mid sized bach demands. The W40 is, like any of our machines, designed for high performance with economic efficiency. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. For industry 4.0 demands, the W40 is best prepared. On option, the control of the machine via OPC-UA server can be installed additionally. By special request, siliconisation of rubber parts or coating with other glide agents is additionally possible. The W40 is the optimal solution for mid-sized batch demands at high througput!

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small-sized machine can be integrated into the production line easily. This safes temporary storage or extra transports and finally corresponding time loss and costs. The comfortable touchscreen panel allows a fast and easy operation of all parameters as well as administration of your washing recipes. Depending on water quality or rather cleanliness requirements, a treatment with de-ionized, de-mineralized or ultrapure water is possible by add-on module on option. By special request, siliconisation or coating with other glide agents is also possible. The W30 uses exchangeable bastekts for the (un)loading. These baskets are also compatible to our cryogenic deflashing machine E30W, and furthermore, optimally suited for a linear in-line processing → production → deflashing → washing → postcure tempering, The W30 is best pepared for industrie 4.0 demands. (on option with OPC UA server) With this small-sized machine, your treatment capacity is at best cost-performance ratio!

Request for a quote

SCHOLPP GMBH

Germany

Well connected: installing system electronics. Today’s machines are not just mechanical. They have sophisticated electric and electronic components, information technology and data transmission systems. This is why it goes without saying for us that we take the same care when reconnecting these elements as we do with the mechanical parts and components. Electrical and electronic installations are just as much a part of our services as the subsequent I/O checks. We also have specialists in programmable logic controllers (PLC technology). Relocations are often a good opportunity to equip older systems with the latest, more efficient electronic components and operator’s stations. You can always ask our engineers any questions you might have about the control system hardware and software programming. Our carefully planned solutions for digitalizing and networking production systems support our customers on their path toward Industry 4.0. The electronics and electrics in today’s...

Request for a quote

HONSEL-GROUP

Germany

Small. Light. Smart. Industry 4.0 ready! With RivSmart you can now take the first step towards blind rivet processing of tomorrow – on the basis of decades of experience in the development of high-quality riveting tools and customised riveting automation technology. RivSmart can be easily integrated into our production processes, and with its documentation capabilities helps to optimise optimise and monitor production. Compact dimensions: Thanks to the removable transparent collecting bin, the tool can be further shortened for unrivalled ease of handling for even the most confined installation points. Weight only 1.3 kg. Documented process monitoring: RivSmart is equipped with the DMSD-lite process monitoring system. Serious errors can already be detected here and the number of set fasteners counted. Intelligent controller: In addition to its outstanding riveting properties, the RivSmart eBZ ZERO S is prepared for integration into an increasingly networked production environment.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ADS-TEC INDUSTRIAL IT GMBH

Germany

Big-LinX is an IIoT service & maintenance platform for secure remote maintenance of machines and systems, as well as for Industry 4.0 and IIoT applications. Due to remote maintenance, expensive machine downtimes can be minimised or even prevented thanks to preventive and direct interventions. Prepare machine data graphically in dashboards via the cloud and set up alarms. The alarm function is used to inform previously defined employees about a possible malfunction. Big-LinX offers customers a secure investment in the future, as the portal grows with the customer's needs. Get your company ready for digitalisation.

Request for a quote

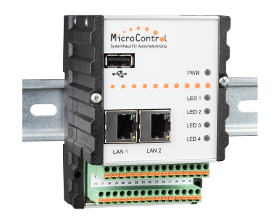

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

Real-time Linux, Ethernet, CAN, USB plus custom electronics in a space-saving metal top-hat rail casing. In its µMIC.200 family, MicroControl integrates the best of the world of automation for IoT/Industry 4.0. The unit is equipped with COMBICON® connectors and offers versatile connection facilities for digital signals, CAN bus and RS-232. I/O modules with CAN interface can be connected to the unit via the integrated CANopen FD Master library. An even higher flexibility is offered through its customizable electronics. Two boards perfectly matched. CPU board and high performance standard board or – alternatively – a CPU board and a custom board tailored to your specific needs. The metal casing is able to withstand extreme operating environments. And all this at most favourable terms.2 Ethernet interfaces 2 CAN interfaces (isolated) 2 x RS-232 (isolated) CANopen Master function Cortex-A8 CPU with USB interface of 1 GHz frequency 4 GByte Flash and 512 MByte DDR3 RAM

Request for a quote

EWOQE GMBH & CO. KG

Germany

The start at EWOQE marked the beginning of an ambitious expedition. With determination and the firm goal of making significant progress in the B2B sector in mind, we set out to forge new partnerships. As a modern company, we have prepared ourselves from the outset to operate globally in the dynamic world of Industry 4.0. The fruits of these efforts are visible today in the form of business relationships across Europe, Asia and the USA – a far-reaching network. The diversity of our projects shows that innovation often starts where you least expect it. In the peaceful community of Bersenbrück, which includes our Eggermühlen facility, one such opportunity presented itself. Despite its rural charm, the region is a vibrant economic area filled with medium-sized companies. Our latest collaboration with a local farmer is not only a testament to the adaptability of 3D printing technology, but also an exciting chapter that shows how EWOQE turns challenges into successes.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The P 250 Test Bench with Control C.2 IPC is a new modular test bench that can be adapted to your needs. It offers the possibility to test with Steck-o, Hand or Hydraulic quick cone system. You can also install a Euro Pallet inside. The Chamber also accepts a non-end extension if you prefer to test a hose lengthwise. The controller offers all parameters for a fully automatic test, with visualization of the pressure and may other features but also connectivity to your server or other machine in line with industry 4.0. Quality and safety •Fully enclosed test chamber •Also suitable for static pressure testing of various hydraulic components such as valves, hydraulic cylinders, housings, quickrelease couplings, etc. •Safety switch - when the hood is opened, all pressure is automatically released within 1/10 second •Environmentally friendly test medium (water-oil emulsion) •Easy and safe to operate •Quick changeover between automated and manual setup mode

Request for a quote

ORBITEC GMBH

Germany

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters. The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions... Package includes: — Orbital welding system — Display transport protection — Calibration certificate — USB stick Optional: — Water Cooling Unit COOL 50 or EVO COOL — EVO Remote Control — Gas Controller Box

Request for a quote

ORBITEC GMBH

Germany

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters. The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions... Connection to Tetrix 200 or Tetrix 351. Compact and light with the external dimensions (L x W x H) 405 x 325 x 170 mm and weighing only 9.7 kg. Optional: — Water Cooling Unit COOL 50 or EVO COOL — EVO Remote Control — Gas Controller Box

Request for a quote

BERNSTEIN AG

Germany

The SRF (Safety RFID) is a non-contact safety sensor, that monitors moveable safety guards, such as doors, flaps and hoods. With its innovative diagnostic system, the SRF makes safety circuits suitable for Industry 4.0. The system provides a multitude of diagnostic data of each sensor, even in a series connection, to support smart production. Diagnostic data is fed into the machine control system via I/O Link or alternatively displayed on a smartphone by way of NFC technology. In this way, 20 different diagnostic information of each sensor can be retrieved and made available. This diagnostic data delivers cost-effective predictive maintenance in a simple way. Through its advanced fault recognition capability, costly machine shutdowns can be prevented. This way, your machinery and plant will work even more efficiently!

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Screen Printer G Titan JUKI’s G TITAN is equipped with premium quality functions empowering the JUKI Screen Printing Solution on its path to Industry 4.0 and “Lights Out Manufacturing”. Ease of use is provided due to a brand new GUI – Graphical User Interface – which is operated via touch screen. G TITAN supports circuit boards of sizes up to 510 × 510 mm and therefore addresses its demands towards the mid size segment. Innovative novelties such as the Opti Paste Control – OPC – as well as the Quality Print Control – QPC – represent useful individual functions to achieve optimised paste consumption, higher level of automisation and avoidance of printing errors during the screen printing process.

Request for a quote

HERMA GMBH

Germany

Powerful: Fast set-up thanks to innovative technologies such as motorised liner feed & automatic label length detection. Label at speeds from 30 m/min up to 200 m/min. Networked: State-of-the-art interfaces for tomorrow's machine communication. Industry 4.0-capable thanks to OPC and Ethernet interface as well as configurable fieldbus connection. Web functionality, as well as online registration for fast support, function upgrades & firmware updates. Reliable: Long-term availability of all parts and future-proof interfaces for digital challenges. Comprehensive service worldwide, at your site or in HERMA Online Services. Universal: Whether pharmaceutical, cosmetics, food or other industries - the HERMA 500 is suitable for all sectors thanks to the highest standards in security and quality.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

Being the smallest model of the new Q series, the Q 1500 achieves precise plasma cuts at the highest level for material thicknesses of up to 60 mm and with a maximum cutting current of 150 A. New components and especially the operator interface Q-Desk meet the complex requirements of a digitalised production in the age of Industry 4.0. The specially developed browser-based operator interface Q-Desk provides real-time process data and information of all plant components on any standard device and location-independent. The user benefits from extensive information enabling him to plan and execute a variety of maintenance tasks as guided by the system. This generation of plasma cutting systems is the result of intensive research and development work by Kjellberg and a landmark in the 60 years of Kjellberg's plasma history. The new digital plasma series Q sets pioneering standards regarding quality and connectivity.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The plasma cutting machines Q 3000 and Q 3000 plus combine precise, highest-level plasma cutting and marking with a maximum cutting current of 300A. Thanks to the modular design, the machine performance of the Q 3000 plus can later be upgraded and, thus, adapted to the customer's requirements. The specially developed browser-based operator interface Q-Desk provides real-time process data and information of all plant components on any standard device and location-independent. The user benefits from extensive information enabling him to plan and execute a variety of maintenance tasks as guided by the system. This generation of plasma cutting systems is the result of intensive research and development work by Kjellberg and a landmark in the 60 years of Kjellberg's plasma history. The new digital plasma series Q sets pioneering standards regarding quality and connectivity.

Request for a quote

COGNEX CORPORATION

Germany

Machine vision tools and barcode reading systems produce a lot of insight-rich data across manufacturing and logistics facilities. The expansion of Industry 4.0 through the Industrial Internet of Things (IIoT) focuses on improving operations by collecting and analyzing data in an efficient way like at “the edge” of the production line as opposed to sending data to the cloud and back. The Cognex Edge Intelligence (EI) platform transforms big data into smart data and provides real-time system performance monitoring and device management to improve overall equipment effectiveness (OEE) and throughput. EI device setup is fast and simple for both new and existing automation lines, preventing downtime and boosting productivity for your operation. Easily connect to the EI platform through any web browser to start collecting data right away. Additionally, users can configure and manage several devices at once.

Request for a quoteResults for

Industry 4.0 - Import exportNumber of results

30 ProductsCountries

Category

- Rubber - industrial machinery and equipment (7)

- Metal detectors (2)

- Metalworking - portable power tools (2)

- Plasma cutting machines (2)

- Welding, soldering and brazing - equipment and supplies (2)

- Monitoring and control equipment (1)

- Agricultural machines and accessories (1)

- Bar code scanners (1)

- Electronic data processing - microcomputers (1)

- Industrial screen printing (1)

- Inner tubes (1)

- Labelling machines (1)

- Machine vision system (1)

- Risk and production management (1)

- Safety shields for machines (1)

- Sensors (1)

- Tools & Hardware (1)

- Vehicles - mechanical components and parts (1)