- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial fabrics

Results for

Industrial fabrics - Import export

SPANDAUER VELOURS GMBH & CO. KG

Germany

Our modern machine pool allows us to produce a wide variety of three-dimensional, technical plush fabrics in different heights, yarns and fibre blends. You benefit from our many years of experience in a wide variety of applications, from painter rollers and cleaning plush fabric to plush fabric for textile washing facilities or individual solutions. We use a wide variety of natural and synthetic fibres, which allows us to find a suitable solution for every application. We also offer lint-free products, of course. In addition to our tried and tested basic qualities, we also develop individual solutions for abrasive and non-abrasive cleaning plush. We can produce plush fabrics tailor-made to your needs using a variety of yarns, fibre blends and coatings. This also includes cleaning plush fabrics for use in fully automatic cleaning systems. We make particularly hard-wearing plush fabrics for textile wash facilities, which have been specially developed for use in wet or dry

Request for a quoteFAUDI GMBH

Germany

Advantages The multiple options enable us to fulfill special customer requests in a flexible way. FAUDI Belt Filters have the ability to be installed on existing vessels or can be delivered as complete systems with vessels, pumps, heating, cooling and control systems. Area of application For the continuous cleaning of coolants, especially emulsions and oils of machine tools and cold rolling mills. For the filtration of liquids with a high demand on purity. The impurities may vary in size, shape and material. Flow rate Various filter sizes and the modular design enable any required flow rate. Interest in our products? Contact us! Download product brochure Classification number - Filter aid with Filtration degree 30-40 µm Medium liquids of the chemical industry Filter material non-woven fabric

Request for a quote

EMPAC GMBH

Germany

Pactainer ED® offers a safe protection against electrostatic hazards. They can be used for bulk goods which contain or are located in areas where electrostatic hazards are at present. For example for the chemical industry. The conductive fabric of a Pactainer ED® conducts the charge of the bulk products to the hoist in connection with the grounded straps and prevents reliable every kind of discharge which displays a risk of fire. A micro-perforation of all coated components of the inside and outside of the container which are connected with each other, guarantees that they are able to discharge the electrostatic energy. This process has already been patented. Pactainer ED® offers further safety: If there is not direct grounding of the lifting loops, the carriers of the charge will be handed over locally and defined to the hoist. This is realized by a Carona-Effect. The Surrounding area is not subject to static charging. Fields of application: Transport and storage container for products produced by the chemical as well as paint industry for bulk goods of every kind – which own low minimum ignition energy. Main industries: Products for the chemical and pharmaceutical industry, wood and synthetic products, food, detergents

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POREX TECHNOLOGIES GMBH

Germany

Increase efficiency of vacuum-based cutting tables To help manufacturers in the automotive, textile, and furniture industries more effectively hold upholstery, fabric, and textile roll stock flat onto vacuum-based cutting tables, we designed POREX ® vacuum hold-down sheets. With its unique technology, our vacuum hold-down sheets: Increase vacuum hold-down system efficiency – Specifically designed porous surface efficiently draws air to pull textiles onto a table for computer-based cutting. Minimize vacuum loss – The consistent pore structure of the sheets ensures low back pressure. Ensure durability – Material hardness withstands repeated scoring from a mechanical razor. Features Consistent pore structure evenly distributes vacuum suction High hardness withstands repeated scoring from a mechanical razor Strong and rigid for maximum service life and effectiveness Materials Offered Advanced porous materials (PE, PP) Formats Available Single piece sheets – multiple dimensions and...

Request for a quote

SGL TECHNOLOGIES GMBH

Germany

Based on carbon and glass fibers, we produce isotropic non-wovens with different fiber orientations and lengths. The non-wovens are made of 100% recycled materials.

Request for a quote

SGL TECHNOLOGIES GMBH

Germany

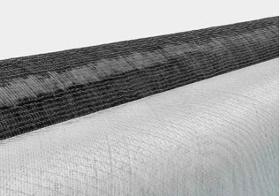

In our weaving facility, we produce a wide range of SIGRATEX woven fabrics and tapes. We use 1k, 3k, 6k, 12k, and 24k carbon fiber tows as the material basis. In hybrid woven fabrics, we also process glass and aramid fibers.

Request for a quote

SGL TECHNOLOGIES GMBH

Germany

SIGRATEX non-crimp fabrics (NFC) are high-quality textile reinforcing materials that we produce for our customers from our SIGRAFIL 50k carbon fiber or from glass fibers. Our portfolio includes uni- and multiaxial fabrics, which we offer in various fiber orientations, areal weights, widths, and stitching types.

Request for a quote

ASP GERMANY

Germany

The very different requirements created by diverse welding techniques mean that specific products have to be specially developed. The industrial fabrics we use have specific coatings that leave the cover flexible but resistant to spatter and weld splashes. Their para-aramid base has excellent mechanical strength. Production tooling protection is a necessity. ASP offers a wide range of protective covers for all types of welding guns, regardless of the welding technology involved (pneumatic, hydraulic or electric motor).

Request for a quote

ASP GERMANY

Germany

n machine tending or direct machining (deburring, cutting, etc.), ASP covers are perfectly suited to machining environments encountered in the car industry. The fabrics employed satisfy the strictest requirements (resistance to wear, oils, shavings and chips, dust, abrasion, etc.) Covers that are tailor-made and repaired in our workshop provide the best protection for your robots in all typical hostile environments.

Request for a quote

ASP GERMANY

Germany

ASP also produces protective covers for the food industry that comply with European regulations. ASP’s range of protective covers for the food industry is manufactured from fabrics coated on one or two sides or from a non-woven PE-based material. They are resistant to high-pressure water blasting, intense cleaning with disinfectants and are resistant to wear & tear. Our experienced teams work together to produce the exact accessories required for your protective cover to ensure a perfect fit that matches your needs. Furthermore, our protective covers are ventilated, which is useful when your robotic machinery remains in operation over long periods. TEXPRAL-B, T1A and FPE comply with regulatory requirements FDA 21 CFR Cap. 1 - § 177.1600.

Request for a quote

ASP GERMANY

Germany

ASP also produces protective covers for the food industry that comply with European regulations. ASP’s range of protective covers for the food industry is manufactured from fabrics coated on one or two sides or from a non-woven PE-based material. They are resistant to high-pressure water blasting, intense cleaning with disinfectants and are resistant to wear & tear. Our experienced teams work together to produce the exact accessories required for your protective cover to ensure a perfect fit that matches your needs. Furthermore, our protective covers are ventilated, which is useful when your robotic machinery remains in operation over long periods. TEXPRAL-B, T1A and FPE comply with regulatory requirements FDA 21 CFR Cap. 1 - § 177.1600.

Request for a quote

WILHELM MEIER SPINDELN U. DREHTEILE GMBH + CO. KG

Germany

Threaded stems (spindles) from our serial production are used for example in the actuator technology for medical engineering and for the furniture industry. The fabrication steps used for the serial stems (spindles) usually consist of thread rolling or whirling with a subsequent turning process.

Request for a quoteResults for

Industrial fabrics - Import exportNumber of results

15 ProductsCountries

Company type