- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- induction sealing

Results for

Induction sealing - Import export

BALLERSTAEDT & CO. OHG

Germany

One-piece induction liners reliably close containers of any make or type using an induction sealing device. The unique features of these liners are: leak-proof, product freshness, tamper-proof and economical. A special quality for induction sealing of glass containers is availbale. Advantages One-piece liners Peelable Special qualities for sealing plastic and glass containers Leak protection Tamper evidence Protection against external influences

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

One-piece induction liners reliably close containers of any make or type using an induction sealing device. The unique features of these liners are: leak-proof, product freshness, tamper-proof and economical. A special quality for induction sealing of glass containers is availbale. Advantages One-piece liners Peelable Special qualities for sealing plastic and glass containers Leak protection Tamper evidence Protection against external influences Delivery MOQ: 10,000 pcs per size Different shapes, sizes, material specifications and designs with or without pull tabs Customer specific design possible using digital print (also small batches) application areas Pharmaceutical industry Food industry Cosmetics industry

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling and sealing machine – Autotwin → Filler and sealer stand next to each other Machine performance: 25 – 30 jars/min Special features: Film applicator station Sealing station (optional induction sealing system for glasses) Separate dosing unit

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

Material on reels is the alternative to punched platelets and is used in packaging production lines with "inline" punching. The features are identical to the pre-punched seals. We offer various qualities, which can be used for conductive or inductive sealing, e.g. of paste tubes, in an inline process.

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling and closing machine for viscous products Machine performance: 60 cycles/min. max. 3 600 jars/h Special features: Dosing pump with motorised adjustment from 0-500 ml Heatable hopper with agitator Filling nozzle with recovery system (drip-free) Film applicator station (from film magazine or die) Sealing station (conductive system or induction sealing) Capping station

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling, sealing and capping machine for viscous products Capacity of the machine: 60 cycles/min. max. 3.600 jars/h Special features: Dosing pump with motorised Adjustment from 0 – 500 ml Heatable hopper with agitatork Output of the filled jars to the cooling tunnel and return to machine for sealing and capping Heatable filling nozzle with recovery system (drip-free) Foil lay-on station (from foil magazines or with punching tool) Sealing station (conduktive system or induction sealing) Capping station

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

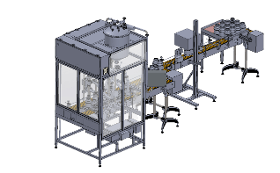

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

CL MACHINERY GMBH

Germany

Closure Systems International's HT6 Headset is a non-ratcheting style headset that incorporates the most advanced hysteresis technology. The HT6 headset is specifically designed for unique specialty applications that are very sensitive to torque variations. Improved Application Torque Consistency Unique magnet configuration provides constant static torque Preferred solution for: ✓ Closures without sidewall knurls ✓ Bottles without neck support rings ✓ Closures with induction seals Low Maintenance Cost 6,000 hours of maintenance-free operation No lubrication required during 6,000 hour scheduled maintenance interval Unique hub configuration eliminates need for daily / periodic lubrication Can be retrofitted to existing installations Headset Exchange and general overhauls available Durable Corrosion Resistant Design Enclosed magnetic system made from high grade stainless steel to prevent corrosion Fully washable Unmatched Technical Support / Application Expertise!

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

Material on reels is the alternative to punched platelets and is used in packaging production lines with "inline" punching. The features are identical to the pre-punched seals. We offer various qualities, which can be used for conductive or inductive sealing, e.g. of paste tubes, in an inline process.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

OPTIMA CONSUMER GMBH

Germany

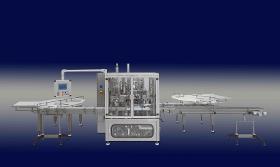

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Container transport using pucks for flexible production and fast conversion - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps - Processing packaging material from the stack

COGNEX CORPORATION

Germany

The MX-1502 vision-enabled mobile terminal reads codes from as near as 15–30 cm to as far as 10 meters away, making it ideal for scanning barcodes on floor labels, rack labels on high shelves and slips hanging from warehouse ceilings. The MX-1502 is equipped with modular lighting and optics technology (including polarized LEDs and a high-powered lens with liquid lens technology) which provides optimal image formation of any code - even the most challenging direct part mark (DPM) codes. The industrial-grade, rugged housing can handle up to 50 drops from 2 meters onto concrete. It is IP65 sealed and uses inductive wireless charging so there are no exposed electrical contacts to wear out or fail.

Request for a quote

COGNEX CORPORATION

Germany

The MX-1000 is ideal for reading 1-D/2-D or DPM codes on automotive parts and label-based barcodes on packages and equipment. The flexible design accepts a variety of both current and future generation mobile devices and augments their capability in a fully ruggedized housing tough enough to stand up to the most challenging environments. The industrial-grade, rugged housing can handle up to 50 drops from 2 meters onto concrete. It is IP-65 sealed and uses inductive wireless charging so there are no exposed electrical contacts to wear out or fail.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Induction sealing - Import exportNumber of results

17 ProductsCountries

Company type