- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- impact sensors

Results for

Impact sensors - Import export

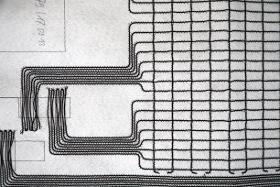

EMBRO GMBH

Germany

At Embro, we develop and produce customised, textile-based surface sensors in large dimensions. Applications include: > pressure sensors > impact sensors > detection and monitoring of composites > surface temperature sensors > area sensors for humidity and damage sensing > inductive sensors > capacity sensors

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

High-precision pressure sensors from the 8201 series provide exact measurements while exhibiting very little sensitivity to mechanical stresses. Their application therefore goes well beyond research and development laboratories. They are also outstandingly suited to industrial use in quality assurance or for measurement and control tasks in production. Their robust mechanical and electrical construction guarantees good long-term stability and high reliability, while being resistant to aggressive media – which can be measured in liquid or gaseous states. The structure of the sensors includes no mechanical moving parts, which is why they show so little sensitivity to impact and vibration. The pressure sensors can be configured with options to suit the user. Standard types are available ex-stock, and customized customer versions can also be provided. Aeras of application are: —Research and developmemt —Test rigs —Mechanical engineering —Plant control and monitoring

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE inductive sensors for high mechanical loads still work trouble-free even after 10 impacts of 8 Joule. The sensor protected by a solid stainless steel sleeve is thus particularly resistant to shock and vibration. They are ideal for areas where standard sensors could be damaged mechanically. EGE offers variants resistant to high pressure cleaning with protection class IP 68/IP69 for use at temperatures up to 110° C and contamination-resistant sensors with PTFE coating. The proximity switches are based on the proven inductive principle and switch con tactless when a metallic object moves close. The sensors are particularly suited for heavy duty use, for example in metal processing, during welding and in mobile machinery.

Request for a quote

3D-MICROMAC AG

Germany

The microVEGA™ xMR system provides high throughput laser annealing for monolithic magnetic sensor formation. A highly flexible tool configuration, the microVEGA™ xMR can accommodate both Giant Magnetoresistance (GMR) and Tunnel Magnetoresistance (TMR) sensors, as well as easily adjust magnetic orientation, sensor position and sensor dimension—making it an ideal solution for magnetic sensor production. The microVEGA™ xMR uses on-the-fly spot and variable laser energy to provide selective heating of the pinning layer in each sensor in order to “imprint” the intended magnetic orientation. Magnetic field strength and orientation is adjustable by recipe, while high temperature gradients ensure low thermal impact. This allows sensors to be processed directly next to readout electronics as well as closer together, and enables the production of smaller sensors—freeing up space for processing more devices per wafer.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Impact sensors - Import exportNumber of results

4 ProductsCountries

Company type