- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic brakes

Results for

Hydraulic brakes - Import export

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

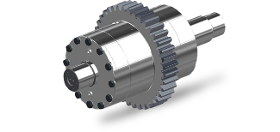

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Most durable hydraulic wedge type expansion, easily operable even under weight Highestquality reel arbor with doubled maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability SHH Series PullOff Reel with manually adjustable brake and auxiliary drive to support coil setup SHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic or hydraulic hold down arm Electropneumatic brake system Electromotive or hydraulic traveling feature Hydraulic coil car Concical keeper rolls w optional motorized travel Larger mandrel segments Different mandrel heights Fullsize back plate Vectorcontrolled drive system for heavy coil weights Servo drive and control system Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

GSW SCHWABE AG

Germany

Movable keeper arms for coil guidance and centering Crank expansion via directionally stable joints, easily operable even under weight Highestquality reel arbor with maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability MH Series PullOff Reel with manually adjustable brake MHM Series Payoff Reel with threephase motor for start / stop operation MHR Series Payoff Reel with threephase motor and frequency inverter for continuous operation Pneumatic or hydraulic hold down arm Electropneumatic brake system Hydraulic expansion Hydraulic coil car Auxiliary drive Traveling feature w optional automatic centering Larger mandrel segments Different mandrel heights Fullsize back plate Loop control systems...etc. Double End Coil Reels w 180° turning radius Horizontal Coil Reels Recoilers Custom Layouts and Features

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Alternator 28V for FERRUM wheel loader . 24-volt systems must be supplied with 28-volt charging voltage to remain intact. Version for 5-pin charge controller. We usually use this model in the brake-assisted models DM308 x4 (V1 & V2), DM312x 4 & DM416 x4 (only V2 and not V1!)

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

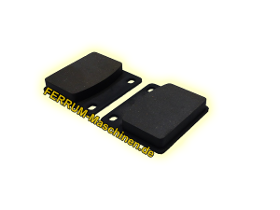

Set of brake pads main brake (hydraulic foot brake) for wheel loader FERRUM DM620x4 - consisting of 2 pieces as shown.

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Brake disc main brake (hydraulic foot brake) for wheel loader FERRUM DM620x4 - scope of delivery consisting of 1 piece as shown.

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Brake caliper complete including set of brake pads main brake (hydraulic foot brake) for wheel loader FERRUM DM620x4 - consisting of 1 piece of assembly as shown.

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Charge controller 28V for FERRUM wheel loader . 24-volt systems must be supplied with 28-volt charging voltage to remain intact. This is the version for the alternator with hydraulic brake booster based on vacuum. Advantages over the compressor system are: no noise when the excess pressure is released no condensation when the air is compressed, no possible freezing in winter therefore no need for an air drying cartridge

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

Drum brake complete with set of brake pads and hydraulic cylinder for wheel loader FERRUM DM416x4 & DM312 x4 - consisting of 1 piece of assembly as shown.

Request for a quote

ALPHA LASER GMBH

Germany

The ALM laser system is particularly suitable for welding large molds and tools, housings and machine components - wherever mobility and maneuverability are required. With the ALM you have exactly the mobility you need for welding. No matter whether in your own workshop or on site at the customer. The laser is ready for use within a few minutes. The arm can be quickly adjusted to the area to be welded and fixed in the desired working position using electro-hydraulic brakes. The operator then has the option of welding manually using a joystick or semi-automatically. One or more axes are automatically moved at a preset speed and with the joystick curves can be driven or small corrections made.

Request for a quote

KLN ULTRASCHALL AG

Germany

The REK-B offers all advantages of the high technical level of the OMEGA III series, particularly regarding precision and reliability. The machine may be integrated in an automatic production line and controlled via a higher-ranking control system (PLC). Options: • Hydraulic oil brake • Working table • Housing • Light curtain • Rotary table • Control of external periphery Advantages: • Easy programming via touch panel TP 270 • Display of time-travel curve and pressure-time curve after the welding cycle on a graphic display with plain text. • Regulation of the welding forces via proportional valve technology. • The machine REK-B offers many possibilities for analysis, control and regulation. • Three welding models in order to meet the requirements of each application • Positioning of the spin head prior to and after the welding process • Display of the ongoing process parameters ( welding travel, -time).

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Manufacture by machining is battling against the rising cost of materials and long machining times. That's why many companies are finding our forming process for hollow parts of increasing interest. We have other forming options for machine-finishing in-house. Our cold-forming process is distinctive – including for thin-walled hollow parts because of: rolled (chip-free manufacture) external threads suitable surfaces for maximum corrosion requirements Some examples of Conform® hollow parts and nuts: sensor housing union nuts for hydraulic, brake and fuel lines clinch nuts

Request for a quoteResults for

Hydraulic brakes - Import exportNumber of results

15 ProductsCountries

Company type