- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- highly wear-resistant

Results for

Highly wear-resistant - Import export

HS UMFORMTECHNIK GMBH

Germany

We can offer single elements like bends, branches or tubes of HVA NIRO® (highly wear-resistant version) or 3.3 borosilicate glass.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Highly wear-resistant reducers of type HVA NIRO® stainless steel are also available in all sizes and diameters. They have the following specifications: widened and welded material no. AISI 304 / 304L other lengths are possible at request

Request for a quote

IGUS® GMBH

Germany

iglidur® V400: Wear resistant at high temperatures High resistance to media and temperature. Highly wear-resistant bearing materials. Bearings for soft shafts and temperatures up to +200°C with low moisture absorption and excellent resistance to chemicals. iglidur® V400 is available as cylindrical bearings and plain bearings with flange. Extreme wear resistance with soft shafts and in high temperatures up to +200°C Chemical resistant High elasticity

Request for a quote

IGUS® GMBH

Germany

igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations Delivery program: Delivery program: Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60 igus® presents world's first tribological 3D filament for 3D printers. The tribological 3D printing material is up to 50 times more abrasion-resistant than conventional 3D print materials igus® has been researching the 3D printer filament field to provide its customers with even more flexibility. Real useable parts can now be produced for prototyping. At the moment we offer two materials: the highly wear resistant iglidur® I170-PF and the flexible iglidur® I180-PF. igus®' 3D printer material starter kits are now available in weights from 25 g and diameters of 1,75 mm - 3 mm. Typical applications:Prototype construction, small batches, test installations igus® presents the first tribo filament for 3D printers The new 3D printing materials are up to 50 times more abrasion-resistant than conventional 3D print materials. Complete processing instructions for iglidur® I170-PF (PDF) Complete processing instructions for iglidur® I180-PF (PDF) iglidur® |180-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Excellent wear behaviour Material table Colour white Moisture absorption at 23 °C and 50 %r.h. 0,3 weight-% Max. water absorption 0,9 weight-% Max. long term application temperature +80 °C Max. short term application temperature +90 °C Minimum application temperature -40 °C Delivery program: iglidur® |170-PF Hotend temperature: 220 - 250 °C Bed temperature: 90 - 110 °C Outstanding wear behaviour of the tribo filaments Harder to process Material table Colour yellow Moisture absorption at 23 °C and 50 %r.h. 0,5 weight-% Max. water absorption 1,6 weight-% Max. long term application temperature +75 °C Max. short term application temperature +85 °C Minimum application temperature -40 °C Delivery program: Y = rate of wear [µm/km] * moulded Wear linear: v= 0,1 m/s; p= 1 MPa; l= 5 mm Y = rate of wear [µm/km] * moulded Wear pivoting: v= 0.01 m/s; p= 1 MPa; ß= 60

Request for a quote

IGUS® GMBH

Germany

Lubricant- and mainteance-free Easy to cut Adherent For compact areas Typical applications:Mechanical engineering, materials handling, fixture construction, installation technology, etc. iglidur® Tribo-Tape A180 Delivery program: iglidur® Tribo-Tape V400 Delivery program: Material: iglidur® A160 Low coefficient of friction Best wear-resistance Upto +100 °C Compared to similar thin plastic films, the cost-effective iglidur® A160 tape has a very high wear resistance. Material: iglidur® V400 Extremely wear resistant Highly resistant to media Upto +200 °C The extremely wear-resistant and at the same time very media- and temperature-resistant iglidur® V400 tape shows up to 10 times higher wear resistance in the test compared to special products for machine beds and the like. Lubricant- and mainteance-free Easy to cut Adherent For compact areas Typical applications:Mechanical engineering, materials handling, fixture construction, installation technology, etc. Wear rotating against stainless steel pin (1.4305) F= 35 N, v= 0.5 m/min Y = Wear/mass decrease [mg/km] A = PC | B = compound liner | C = PEEK D = PEEK mod. 1 | E = PEEK mod. 2 | F = PET G = iglidur® A160 Wear rotating against stainless steel pin (1.4305) F= 35 N, v= 0,5 m/min Y = Wear/mass decrease [mg/km] A = iglidur® V400 | B = PTFE bronze compound iglidur® Tribo-Tape A180 Delivery program: iglidur® Tribo-Tape V400 Delivery program:

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

In pneumatic conveying systems, conveying abrasive products – in particular at high conveying speeds – leads to abrasion and thus to wear in the pipe bends. In order to prevent this, the pipe bend of our highly wear-resistant DWR double-skin stainless pipe bends is encased in a second pipe bend, which creates a double-walled chamber. This acts, so to speak, as a “protective shield”: After the wear has taken place on the internal pipe bend, it fills with the product to be conveyed. When this process is completed, you are then conveying „product on product“ – and no further wear is possible! Version I: „Product-on-product” In this variant, the classic “double skin” comes into effect. not suitable for foodstuffs not suitable for material change Version II: „Lined with concrete” lined with extremely hard concrete colour: light grey not suitable for foodstuffs also available: lined with borosilicate glass

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Along with highly wear-resistant stainless steel pipe bends of type HVA NIRO® we offer suitably highly wear-resistant branch pipes. They are available in in all sizes, diameters and angle degrees.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

We can supply you with highly wear-resistant stainless steel pipe bends which have a service life 10 to 20 times longer than that of standard stainless steel pipe bends. This high degree of wear protection is required, for example for conveying fibreglass-reinforced plastic granules or similarly abrasive media. suitable for use of highly abrasive products easy installation no stepped pipe couplings and no flange connections required safe for use with food

Request for a quote

ELKON GMBH

Germany

ELKON pan mixers are preferred all over the world due to their easy and cost-effective maintenance, simple operation and batching performance. From 0,25 m³ to 3 m³ vibrated concrete per batch capacity pan mixers are available in ELKON product range. Advanced Features of ELKON Pan Mixers High batching performance Easy operation and maintenance High homogeneity even with short mixing time Highly wear-resistant mixer wear parts Easy maintenance due to wide maintenance gates and bolted type replaceable linings Low maintenance cost

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: The solid nozzle for everyday use The sewer nozzle is best suitable for a heavy everyday operation. With its 10 to 12 nozzle inserts and two different jet angles it is primarily used for the all-round cleaning of pipes up to 800 mm in diameter. The sewer nozzle has patented fluid mechanics (patent no.: DE 19516780) and is made of highly wear-resistant special steel. This universal nozzle of heavy construction is characterized by high efficiency and absolute reliability. It is an efficient and low-cost alternative to the conventional standard products.

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: Top quality nozzle for everyday use The torpedo nozzle is the ideal tool in all cases where high demands are placed on cleaning and pulling properties. Due to the patented fluid mechanics (patent no.: DE 19533654) and the highly wear-resistant material used it sets new standards on cost reduction and increase in efficiency. The torpedo nozzle that belongs to the most efficient sewer cleaning tools was designed for cleaning lines up to 400 mm in diameter. Two different jet angles contribute to an effective transport of dirt and silt. The torpedo nozzle can cope with difficult tasks in round as well as in egg-shaped pipes.

Request for a quote

ELKON GMBH

Germany

ELKON twin shaft mixers, which successfully produce concrete for various projects all around the world, has been manufacturing in ELKON’s technological factories for long time. ELKON is capable of producing 500 twin shaft mixers per shift annually thanks to its fully automated robotic welding lines. Advanced Features of ELKON Twin Shaft Mixers - Longer lifetime with robust mixer body manufactured by fully automatic welding robots - Able to produce of all kinds of concrete (Ready-mixed concrete, precast concrete, roller-compacted concrete-RCC, heavy concrete, etc.) - High homogeneity even in shorter mixing times - Highly wear-resistant, durable wearing parts - Easy maintenance due to wide maintenance gates and bolted type replaceable linings - Heavy duty gearbox (Brevini or Bonfiglioli from Italy) - Automatic lubrication system (Lincoln - Germany) - Universal compatibility to existing concrete plants with compact design

Request for a quote

FORBO SIEGLING GMBH

Germany

In practically every sector of the printing industry, machine tapes convey, fold or package printed or unprinted paper. For decades, Forbo Movement Systems has had a reputation as a partner in development and supplier for machine manufactures and users in the paper, printing and packaging industry. In this industrial sector, Siegling Extremultus machine tapes and Siegling Transilon conveyor belts are the first choice for nearly all functions and processes. Thanks to the new Siegling Extremultus E line machine tapes, the potential for quality and productivity of tried-and-tested machine designs can be used to the fullest. The highly-modular thermoplastic tension member design with polyester fabric, in conjunction with highly wear-resistant surface, makes applications possible ranging from the sheet feeder to the most varied of machines in the packaging sector.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Regrinding, repainting and remachining The flexible, but also durable, secutex – buffer pad provides reliable protection from expensive damage to your highvalue goods. Often the solution is paramount. Thanks to the integrated perforated plate, secutex – buffer pad can simply be bolted or welded. secutex is a highly wear resistant polyurethane, which was developed 30 years ago for lifting sharpedged components. In the years that followed, new solutions for materials protection and noise reduction were regularly constructed. Thus, today almostall bricks in Europe are moved using secutex protective coatings. secutex protection is almost the industry standard for the lifting and storage of sharpedged metal sheets. For us, health and safety at work is even more important than the prevention of damage to materials. Our expert advisers can present a number of innovative solutions to you whereby, using secutex – buffer pad, noise is prevented directly at source.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

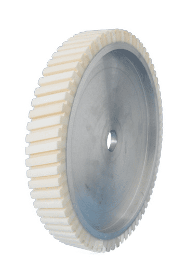

The contact wheel FAPI-VUS/KS is a version coated with lamellae of foamed up Vulkollan® and plastic foam lamellae. The overall height of the coating must also be selected based on the respective application. The alternating lamellae of foamed up Vulkollan® and plastic foam lamellae make the contact wheel especially soft and adaptable. In practice, this contact wheel is used mainly for the finishing of lightly cambered or rounded workpieces. The different material densities result in the heat generated during grinding being drawn off very effectively. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS OPEN is a further development of the dense model. Here the aluminium core is coated alternately with a long and short lamellae of foamed up Vulkollan® . The overall height of the coating must also be adapted to the respective application and is therefore variable (standard: 35 mm). The open model cools better, or respectively it dissipate heat better. The precise adaptation of the soft running cushion to the workpiece makes it possible to achieve high performance results when finishing. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VU SMOOTH is coated with a coating of a smooth lamellae of foamed up Vulkollan®. The coating height can be varied depending on the application. Advantages The contact wheels of the FAPI-VU – series are only coated with a lamellae of foamed up Vulkollan®. Lamellae of foamed up Vulkollan® is cellular Vulkollan®, a polyurethane foamed with water which has very high dynamic properties. Lamellae of foamed up Vulkollan® can be identified by its slightly yellowish colour. Benefits of contact wheels coated with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS/KS is an extremely soft version of a contact wheel with a polyurethane foam and plastic foam lamella coating. The overall height of the coating must also be selected based on the respective application. The alternating polyurethane and plastic foam lamellae make the contact wheel extremely soft and particularly adaptable. In practice, this contact wheel is used mainly for the finishing of strongly cambered or rounded workpieces. Because of the different material densities and the spacing between the lamellae heat dissipates very well during the grinding process. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-PUS OPEN is a further development of the dense design. Here the aluminium core is coated alternately with a long and short polyurethane foam lamella. The overall height of the coating is also adaptable to the respective application and is therefore variable (standard: 35 mm). Because of the variant of the open design, the abrasive belt can better cool because the heat from the belt sanding process is better dissipated. Through the precise adaptation of the extremely soft running cushion to the workpiece that shoud be found it is possible to achieve high-performance results when finish grinding. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the contact wheel FAPI-PUS DENSE, the aluminium hub is coated with dense adjoining polyurethane foam lamellae. The height of the coating resp. the length of the polyurethane foam lamellae can be varied depending on the application (standard: 20 and 35 mm). The polyurethane foam lamellae provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled parts. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-PUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat generated during belt grinding. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VUS DENSE is coated with dense adjoining lamellae of foamed up Vulkollan®. The length of the lamellae of foamed up Vulkollan® can be varied depending on the application (standard: 20 and 35 mm). The lamellae of foamed up Vulkollan® provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled pieces. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-VUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat. Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

AMROC GMBH

Germany

highly resistant to mechanical wear and tear proven impact resistance

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT pressure relief valves for our high pressure pumps ensure optimum working pressure at all times. They can be configured to control pressure either by mechanical pre-adjustment or by remote pneumatic control. We are also able to manufacture many of our pressure relief valves in special materials, making them ideal for the process industry. In addition, our control rods are made from ceramic or stellite, making all our valves highly wear resistant.

Request for a quote

AMROC GMBH

Germany

statically effective paneling highly resistant to mechanical wear and tear high sound attenuation rot resistant, weather and icing proof

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures.Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % Para-Aramid continuous Fiber with PTFE-Blocking Agent and Silicone free dynamic Run-In Lubricant Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Excellent in highly abrasive products Wear resistent universal packing Minimized monitoring, short run-in period Shafts or shaft sleeves in HRC 60 recommended Operating range Pressure [p max]: 25 bar, Velocity [v max]: 25 m/s Pressure [p max]: 500 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 250 bar Temperature: t = -50… +280 °C pH: 2 - 12 Density: 1.25 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Autoclave Refiner Suitable for All industries Chemical industry Waste water technology Pulp and paper industry Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Key data: With hydraulic drive 7.5 to 33.5 kW Stable design, highly wear resisting mechanical seal, shaft in an oil bath The fluidic optimised double blade wide-blade propeller is dimensioned as a pitch propeller with a very high mixing performance. Due to the hydraulic drive, the HP slurry mixers are independent from the power supply and have a favourable purchasing price.

Request for a quoteResults for

Highly wear-resistant - Import exportNumber of results

40 ProductsCountries

Category

- Industrial tools (7)

- Cooling and lubrication pumps (3)

- Hydraulic equipment (3)

- Concrete mixers (2)

- Conveyor belts (2)

- Fibre-cement - products (2)

- Pipes and tubes, stainless steel (2)

- Coupling, pneumatic (1)

- Grinding - steels and metals (1)

- Industrial valves, operating equipment (1)

- Metal brushes (1)

- Reducers (1)

- Steel (1)

- Transmission belts (1)

- Valves for sanitary fittings (1)