- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heating systems - external

Results for

Heating systems - external - Import export

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Settling and floating layers are avoided by horizontal and vertical mixing. Before plant construction, coordination takes place with the future plant operator to determine the optimum stirring technology based on the respective substrates. Operational safety is ensured by the closed reaction chamber, the external drive for the agitator and the externally mounted electric drives. Variable dimensions and substrate flexible stirring technology also allow the use of difficult substrates. The wall heating system, externally mounted on the fermenter wall, ensures optimum fermentation conditions and a high gas yield. FAST ASSEMBLY – LESS COST Low installation costs are possible by using the Lipp dual seam system and on site production. If the foundation slab is provided along with assistance during assembly, costs fall still further.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The smooth internal walls of the LIPP digesters (largely without any internal attachments) ensure gentle, uniform mixing while keeping energy consumption low. If an external heating system is fitted, it will guarantee uniform temperature distribution in the digester. These mechanical and thermodynamic benefits with LIPP digesters mean short retention times. The high functional safety, for heating and stirring technology, ensures a low demand for process energy and this is combined with the benefits of minimal maintenance requirements and a long service life.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. The central agitator has a low energy requirement to ensure mixing and ensures optimum biological digestion. This is helped by the smooth internal walls (largely without any internal attachments) which prevent substrate deposits. As an option, an external heating system can be added to the digester, ensuring an even temperature distribution thanks to the good heat transfer properties of the steel. MAXIMUM LEAK TIGHTNESS AND PRACTICAL ON SITE CONSTRUCTION With Lipp digesters you will benefit from over 50 years experience in plant and tank construction.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

DIGESTER CHAMBER VOLUMES FROM 100 UP TO 10,000M³ The flexible LIPP Eco Digester for use in industry and agriculture can be adapted to individual requirements and customer demands. With a wide variety of different container roofs to choose from, tank solutions with or without an integrated gas accumulator can be offered. KEY BENEFITS Production of renewable energy and reduction of fossil CO2 emissions Low noise emissions Flexibility with regard to substrate composition Customisable pumping and stirring technology High functional safety External heating system available Production on site for quick construction Low investment costs Durable and low maintenance Consistent quality worldwide PRODUCT SPECIFICATION WIDE RANGE OF CONTAINER ROOFS WITH OR WITHOUT A GAS ACCUMULATOR The LIPP Eco Digester has a modular design and essentially consists of a stainless steel container (Verinox) with a digester chamber volume of 100 to 10,000 m3.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

MUNICIPAL AND INDUSTRIAL APPLICATIONS WITH CHAMBER VOLUMES FROM 100 TO 7,000 M3 The LIPP UniCentralmix Digester with its central agitator is designed for industrial and municipal applications. The special feature of this tank, in addition to the central agitator, is the roof construction, with a high quality stainless steel diaphragm cover. The flexible LIPP System ensures each digester can be adapted to each individual application and customer requirements. KEY BENEFITS Energy efficient, central agitator Maximum leak tightness Flexible substrate composition High functional safety Stainless steel diaphragm roof without bolts External heating system available Production on site enables quick construction Low investment costs Low maintenance and durable High quality the world over PRODUCT SPECIFICATIONCENTRAL AGITATOR WITH BOLT LESS STAINLESS STEEL DIAPHRAGM ROOF At the heart of the LIPP UniCentralmix is a stainless steel tank (in Verinox) with a digester chamber

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Stainless steel digester with a digester chamber volume of 100 to 2500 m3 Integrated gas accumulator – fixed in gutter for high operating safety Optimised diameter to height ratio for optimum mixing and minimal stirring Low maintenance, external panel heating system Flexible stirring technology which can be adapted to the substrate and digester Stirring technology can be maintained without having to empty the tank

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

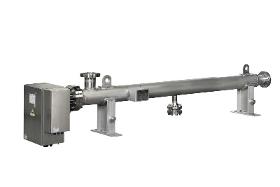

CSN® explosionproof flow heaters are used for heating up flowing gases and liquids in hazardous areas. The devices consist of explosionproof flanged immersion heaters, which are installed in corresponding pipe or pressure vessel. Our products realize individual solutions for complicated technical process. Different heating systems for heating up liquids, nitrogen or other gases activate exact determinded processes in chemical factories. In close discussion with our customers problems will be defined and changed in technical optimale solutions. Our QualityManagementSystem ensures the high quality level of our customers. Further information about our CSN® Exflow heater

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

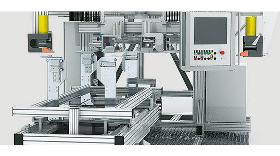

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

nduction Heating and Joining in one turnkey system. This turnkey system is used to heat electric motor housings with various dimensions for a wide range of joining processes. Example Heating System 1: the die-cast aluminium housing for an asynchronous motor (diameter 450 mm) is heated to approx. 290°C in approx. 5 minutes to fit the wound stator package. The parts are loaded and unloaded from the feeding belt parallel to the working time. The heating process takes place in two independent work stations. The generator has a switched output which means that only one generator is required for the two heating stations. The system is controlled using a SIEMENS PLC controller. Example Heating System 2: the aluminium housing (diameter 140 mm) of a synchronous motor is heated to approx. 280°C in approx. 3 minutes to fit the stator. The component is loaded into and unloaded from the heating station semiautomatically. The system is controlled using a PLC.

Request for a quote

SANHA GMBH & CO. KG

Germany

Our quality SANHA ball valves are made of brass CW 617N and can be delivered in a multitude of versions such as with threaded and press ends, or in the dimensions 15-54 mm, 16-26 mm and ½" to 2". The ball valves can be easily and quickly combined with all SANHA systems, thus providing a real alternative to conventional products. With SANHA ball-stop valves we provide our customers with the oppurtunity for an optimal safe and at the same time very economical solution for the installation of machinary, equipment or other facilities such as risers.

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Like the slightly less powerful MA series, it is guaranteed absolutely exhaust-free hot air. In addition, the units can be operated not only with oil, but are also approved for gas operation. The operating mode can be flexibly adapted to the conditions on site. Thus, the devices can be used in all areas. Hot air hose systems can also be connected without any problems thanks to the high-performance radial fans. Consequently, effective heating from outside is also possible without any problems. The recirculation module ensures efficient and economical operation. The oil burner blowers are made of high-quality materials by renowned manufacturers. They work so efficiently that 93% of the energy can be converted into heat.

Request for a quoteResults for

Heating systems - external - Import exportNumber of results

12 ProductsCountries

Company type