- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat forms

Results for

Heat forms - Import export

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of temperature-stressed machine parts, e.g. rolling bearings, friction bearings, slideways, chains, rollers or moving parts in hot forming, heat treatment or drying Dry lubrication, e.g. of kiln and rack-truck bearings, bearings of pouring ladles, converters or hot-air blowers at temperatures over 250°C Lubrication of plastic and rubber at normal temperature when the materials concerned are not resistant to mineral oil Advantages and benefits Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Broad range of applications at temperatures up to 200°C as paste, over 200°C to 450°C as dry lubricant Resistant to water, fuels and lubricants, chemicals and hydraulic fluids For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner.

Request for a quote

VEHGRO B.V

Germany

"What is Coconut Blossom Sugar? Coconut blossom sugar is a sweetener of natural origin, derived from the nectar of the coconut blossom. Coconut blossom sugar is also called 'coconut sugar'. Organic coconut blossom sugar is produced entirely by hand and provides many families with a steady, regular income. The sweet juice of the coconut blossom is heated over a gentle fire, forming a solid block of sugar. Coconut sugar is an easy alternative to table sugar because it has the same sweetening power. How does coconut blossom sugar taste? The taste is one of the reasons to buy coconut blossom sugar. The sugar has something similar to caramel. That full, creamy taste is especially good to taste when the sugar is melted. Because of its caramel taste, coconut blossom sugar is a welcome treat for almost all types of pastries and pancakes. The sugar can also be used in hot drinks or cocktails. The possibilities of organic coconut blossom sugar are endless.<…"

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round tubes are manufactured from a coil that is bent and electric resistance welded (ERW). The forming process can be according to EN 10210, which foresees hot forming or cold forming followed by heat treatment, or according to EN 10219, which foresees cold forming without following heat treatments. The finished product is fully killed and welding seam bead is inside and outside trimmed. These products are used to manufacture both welded and bolted structures, in the field of constructions, engineering, industrial constructions, transports, automotive, agricultural machinery and earth moving machinery. The cold finished tubes are particularly suitable for structures at sight or for aesthetical uses, thanks to the surface aspect typical of cold forming. NORMS HOT FINISHED” TUBES EN 10210-1/2 COLD FINISHED” TUBES EN 10219-1/2 INSIDE TRIMMING EN 10217

Request for a quote

ANTHERMO GMBH

Germany

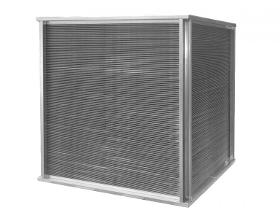

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

ZANDER GMBH

Germany

Bending forms for heat-set plastic pipes Our services We manufacture tools for the molding of plastic pipes according to datasets, drawings and geometric data for two processes: in a convection oven with water vapor Bending molds are in every respect sophisticated tools that meet the rapidly increasing demands of the automotive industry on your products.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Compression Proof and Form Stable Biaxial expanded Joint Sealant Characteristics No change in width at compression Excellent on slim or restricted flange area Technical parameters pH 2 - 12 Temperature: t = -200 … +280 °C Pressure: p = Vacuum … 200 bar Density: 0,95 g/cm 3 Main application Larger flanges and vessels Glaslined flanges Agitators Heat exchangers Form of delivery 10 mtr / roll Other length and dimension on request Suitable for Pharmaceutical industry Food industry Approvals FDA21 CFR 177.1550 (PTFE), FDA21 CFR 170.105 (adhesive) EG 1935:2004 EU 10/2011 FDA Installation Instructions Connect the ends with an angle cut Maximum uneveness of flange: 1/3 of seal tape’s thickness Dimensions thickness (mm) Recommended for Steel Flanges width according DIN 2690 (NW) Surface pressure/ resulting thickness in 10 N/mm2 Surface pressure/ resulting thickness in 20 N/mm2 Surface pressure/ resulting thickness in 30 N/mm2 Surface pressure/ resulting thickness in 40 N/mm2 2 ≤...

Request for a quote

ERC ADDITIV GMBH

Germany

ERC Guard Thermic for low-sulphur heating oil with a bio share and all other DIN heating oils slows the natural ageing of heating oil and contains an organic combustion enhancer. The Effect ERC Guard Thermic slows the natural ageing of heating oil. Stabilisers prevent components of the heating system from releasing into the heating oil and forming sediments, and/or accelerating the ageing of the heating oil. In the process, select active ingredients neutralise the ions already in the heating oil and apply a protective coating to the metal surfaces, which suppresses the release of new ions and protects against corrosion. In addition, the additive prevents the formation of resin-like, adhesive ageing products which arise due to the high thermal load of the heating oil within the pump and can block it. At the same time, lubrication of the pump is improved.

Request for a quote

PERO AG

Germany

The R5 units from PERO are able to clean large quantities as well as large workpieces in a highly efficient manner with short cycle times. Thanks to its large-capacity processing chamber, the R5 is particularly popular with companies in the automotive and aerospace industries, as well as those of forming plants, heat treatment specialists and contract cleaners where high cleaning capacity is a must. Suitably dimensioned tanks guarantee excellent degreasing and cleaning results in single-shift and multiple-shift operation, even at high throughput rates. Cleaning Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Highlights - High flexibility - Maximum throughput - Unrivalled cleaning quality Availability Available as 1- and 2-bath unit with loading of the unit via - Hall trolley - Pallet truck - Automatic charging unit

Request for a quote

PERO AG

Germany

The R4 from PERO is able to clean large quantities of parts as well as large workpieces in a hgihly efficient manner with short cycle times. With its high cleaning capacity, the R4 meets the needs of companies in the automotive and aerospace industries, as well as those forming plants, heat treatment specialists and contract cleaners. Thanks to customised parts carriers and logistics concepts, the R4 offers reliable degreasing and cleaning results for emobility suppliers. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Suitable for 1/2 EURO wire mesh boxes Suitable for largesize workpieces Efficient cleaning to high cleanliness standard Available as 1 and 2bath unit with loading of the unit via Hall trolley Pallet truck Automatic charging unit

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

Request for a quote

POLIFIBRA FOLIEN HANDELSGESELLSCHAFT MBH

Germany

Heat Stabilizing films are polyester films, which do not shrink at heat treatment. They form the basis for the printing of electrical elements and are ideally suited for further processing. If you to have any further questions then please do not hesitate to contact us. We will be happy to explain what to look for heat stabilizing films and what qualities must have the films.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

iwis Leaf chains (according to works standard) are produced from precision chain parts according to ISO 606. They can be customized and are compliant with the EC Machinery Directive 2006/42/EC. Highlights - iwis link plates with very high tensile strengths - Pins with extra hardened surface for high wear resistance - Precision-formed, heat-treated and shot-peened link plates with optimised geometry - Higher breaking forces achieved by optimised plate thickness - Improved press-fitting of pins and outer plates for higher fatigue strength - Link plates with a particularly high contact ratio - Pins with hardened surfaces for increased wear resistance - Special versions manufactured to works standards available

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Heat forms - Import exportNumber of results

17 ProductsCountries

Category

- Cleaning machines, industrial (2)

- Induction heating systems (2)

- Thermoforming, plastics - machinery (1)

- Fuel oil (1)

- Heat exchangers (1)

- Heat recovery systems (1)

- Industrial equipment hire (1)

- Mechanical transmission systems and components (1)

- Moulds and patterns (1)

- Organic food (1)

- Polyethylene (1)

- Silicones (1)

- Vehicles - mechanical components and parts (1)