- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat dissipators

Results for

Heat dissipators - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

The market for an ever-increasing array of consumer electronics parts is made possible by continuing innovation in integrated circuitry, new software applications and the exceptional properties of industrial aluminum, such as its light weight, high formability, superior heat dissipation, electrical conductivity, high corrosion resistance and attractive surface properties. Whether it is smartphones, tablets, laptops or flat screen TVs, aluminum is an integral component in the design, development and production of the latest personal devices and in-home entertainment systems. Novelis is leading the way in producing customized, premium flat-rolled aluminum for many consumer electronics parts and products, including aluminum enclosures and aluminum cases. Our aluminum products, developed according to customer specifications, are supplied in coil or sheet form, then slit or cut to length by third-party distributors or customers themselves.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Smart automation concepts enable us to meet the highest standards of manufacturing. Our products are manufactured in Germany and made in USA, in a cost-efficient manner. Benefit from our production expertise that has been continuously developed over many decades. Mechanical protection, reliable electrical insulation, moisture shielding and heat dissipation - with continuously optimized potting resins (polyurethanes, epoxies, etc.) and potting equipment, PRUFREX is a leader in the field of vacuum potting. When it comes to the safe protection of your electrical and electronic components, our state-of-the-art, automated manufacturing equipment meets all contemporary requirements. The use of specially adapted epoxy and polyurethane potting compounds ensures excellent potting characteristics and the best-possible impregnation of components and coils. These optimised potting compounds also contribute to optimal heat dissipation.

Request for a quote

TROTEC GMBH

Germany

The possibility for wall mounting or installation under the ceiling open wide range of application possibilities, e.g. for heating of building container, marketplaces, greenhouses, small storages, garages, workshops, boathouses or at installation applications. Benefits in pratice: 100% TROTEC - development, design, production Multistage temperature control with up to 3 heating stages Integrated room thermostat for constant, cosy warmth Overheat protection 10% more power than competitive models Fan motor with thermal protection Condensation-free heating - no oxygen consumption - because of that the TDS 30 is suitable for uses in enclosed rooms Standard built-in air baffle for optimization of heat dissipation (guarantees maximum efficiency) Fan function

Request for a quote

XIMEA GMBH

Germany

Extending the xiX camera series with a 32 Gbit/s backend allows the integration of the newest generation of Sony sensors. This product line-up offers large format sensors (150 Mpix, 66.7 mm diagonal) as well as the fast global shutter Sony Pregius™ S sensors, reaching the full sensor specifications at the smallest formfactor. An innovative housing concept with detachable sensor heads optimizes the integration into crowded instruments and the heat dissipation to improve the image quality. Reaching a resolution of 150 Mpix (14,208 x 10,656 pixels) and up to 2 fps pixels. - Highest resolution in XIMEA portfolio of cameras - up to 151 Mpix - Large format backside illuminated sensors from Sony: IMX455, IMX461, IMX411 - Readout of high-quality pictures with 12, 14, 16 bits of digitization - Remarkable bandwidth of 32 Gbit/s using PCI Express interface

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

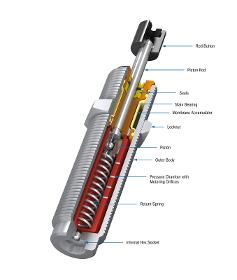

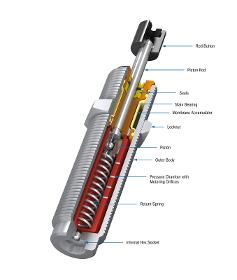

Energy capacity 56.5 Nm/cycle Stroke 18.8 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Energy capacity 56.5 Nm/cycle Stroke 18.7 mm Optimizing PET stretch blow machines: MAXIMACE, the new PET shock absorbers from ACE, shine with longer service life compared to previous solutions and an operating time of over 20 million strokes. They work simply and faster than other shock absorbers and are stronger at the same time. As a result, downtime is reduced and system performance and production volume are increased. This is accomplished by numerous details such as innovative aluminium outer housings for better heat dissipation, improved high temperature seals (up to approx. 107°C), a diaphragm accumulator for faster cycle times and a larger damper chamber which is filled with food-grade oil. All of this significantly contributes to reduced wear and extended service life. These self-adjusting, specialized shock absorbers stand out in their field of PET container production due to their compactness and distinctively colored aluminium bodies.

Request for a quote

XIMEA GMBH

Germany

The xiQ camera series is highly versatile with a selection of popular and established CMOS sensors. The ultra-compact form factor, barely larger than the C-mount, combined with micro-B, and flex ribbon connectors make these cameras the perfect fit for various applications, especially for automation and embedded vision systems. Board-level variants enable custom intgerations into devices and systems, while taped-glass sensor options minimize interference effects in photonics applications. - Most compact cameras - 26.4 x 26.4 x 26 mm small and 27 grams - High frame rate: 500 FPS at VGA and 1000 FPS at 640 x 400 - Low power consumption down to 1 W and minimal heat dissipation - 5 Gbit/s interface 400 MB/s data throughput

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Smartphones, laptops and digital music players rely on the durable, lightweight and attractive qualities of aluminum. Our technically sophisticated material impacts the latest designs, providing both a technical advantage, as well as an attractive visual ambience. Aluminum enclosures dissipate heat, while the material’s resistance to the effects of weathering makes it ideal for use in outdoor applications as varied as housings, rod antennae and satellite dishes.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

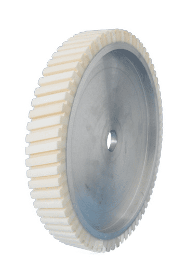

The contact wheel FAPI-PUS/KS is an extremely soft version of a contact wheel with a polyurethane foam and plastic foam lamella coating. The overall height of the coating must also be selected based on the respective application. The alternating polyurethane and plastic foam lamellae make the contact wheel extremely soft and particularly adaptable. In practice, this contact wheel is used mainly for the finishing of strongly cambered or rounded workpieces. Because of the different material densities and the spacing between the lamellae heat dissipates very well during the grinding process. Advantages The contact wheels of the FAPI-PUS – series are coated only with polyurethane foam lamellae. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

RONIX GMBH

Germany

With a good headlamp, you not only bring light into the dark but also always have your hands free. This is useful when you are out in nature at night or want to read in the tent in the evening. Ronix Headlamp 70LM with its robust, light-emitting 1.5W LED, turns night into day. When you pick up the Ronix RH-4280 headlamp, the first thing you notice is the lightweight of the elegant metal housing. It not only makes the luminaire more robust, but it also dissipates the heat from the power LED. This headlamp is very adjustable and sits comfortably on the head. 50 meters illumination range of RH-4280 makes it a great tool for a variety of tasks like running, cycling, and so on.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VUS OPEN is a further development of the dense model. Here the aluminium core is coated alternately with a long and short lamellae of foamed up Vulkollan® . The overall height of the coating must also be adapted to the respective application and is therefore variable (standard: 35 mm). The open model cools better, or respectively it dissipate heat better. The precise adaptation of the soft running cushion to the workpiece makes it possible to achieve high performance results when finishing. Advantages The contact wheels of the FAPI-VUS – series are coated only with lamellae of foamed up Vulkollan® Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

In connection with very precise digital voltmeters the model 1282 resistors are used as measuring resistors for accurate registration of direct and alternating currents up to 200 A. The compact construction supports universal application. The exceptional low temperature coefficient extends the scope of application a second time. A typical application is the wide range of quality and reliability testing. Regular measurements give a reliable information of the quality level of parts, instruments and systems. Technologies already approved with our precision and calibration resistors - which especially guarantee a secure conduction of the dissipation heat - have been transferred to the precision high capacity resistors. Features: — Temperature coefficient ≤ 10 ppm/K — Nominal load 20 W — Ranges 1 mΩ ... 100 mΩ — Four-terminal measurement principle — Accuracy 0.02 % — For technical frequency 50 Hz

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the contact wheel FAPI-PUS DENSE, the aluminium hub is coated with dense adjoining polyurethane foam lamellae. The height of the coating resp. the length of the polyurethane foam lamellae can be varied depending on the application (standard: 20 and 35 mm). The polyurethane foam lamellae provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled parts. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-PUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat generated during belt grinding. Benefits of contact wheels with polyurethane foam lamellae: Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

As the name indicates, the aluminium hub of the contact wheel FAPI-VUS DENSE is coated with dense adjoining lamellae of foamed up Vulkollan®. The length of the lamellae of foamed up Vulkollan® can be varied depending on the application (standard: 20 and 35 mm). The lamellae of foamed up Vulkollan® provide the contact wheel with a “running cushion” with which a fine finish is possible especially when working on (strongly) cambered and profiled pieces. The coating adapts to every workpiece to be found. In addition, the contact wheel FAPI-VUS dense contributes in large measure to abrasive belt cooling because the spaces between the lamellae dissipate the heat. Benefits of contact wheels with lamellae of foamed up Vulkollan® : Highly elastic (adaptable) Wear-resistance Oil-resistance Grease-resistance We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

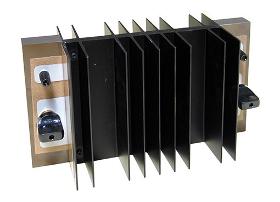

Maximum heat dissipation using PC board heat sinks in minimal board space. Seifert electronic GmbH offers custom heat sinks for use in the board area – precisely measured and flexibly adapted to your requirements. The wide standard range of Seifert electronic includes PC heat sinks in all common designs. We provide various heat sink models such as snap-on heat sinks made of strip material, extruded heat sinks, die-cast heat sinks, as well as finger heat sinks and U-shaped heat sinks, along with the corresponding accessories like mounting clips for fastening. Extruded profile heat sinks are considered classics among PC board heat sinks. We gladly recommend them for use in the board area as they are versatile and can dissipate relatively large amounts of heat.

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

Our thermal management and insulation products are far from being just interim solutions. The Thermal Interface Materials (TIM) from Seifert electronic GmbH ensure optimal thermal connection between heat sinks and the components to be cooled. As electronic assemblies become increasingly compact, even a tiny gap between individual components can disrupt the necessary heat dissipation. Air pockets between the heat sink and the component being cooled hinder the optimal thermal connection. Possible consequences include temperature overload, which can lead to overheating in the worst-case scenario. Thermal management and insulation products act as connectors between the heat sink and the electronic component being cooled. They fill every tiny gap between the heat sink and semiconductor with thermally conductive material. This ensures optimal thermal connection and prevents any heat buildup.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

F.E.S. GMBH

Germany

Automatic Precoat Filter are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Fully automatic operation Excellent filtration results Compact size Low maintenance requirements Full-flow filtration Dry cake discharge with minimal carryover of cutting fluid No fleece consumption Maximum lifespan of cutting fluid Operating Principle: The cleaned cutting fluid is supplied to the filter system pump (1) from the clean tank (2) of the processing machine. The contaminated cutting fluid is introduced into the dirt tank (3) of the cake filtration system through inlet channels or lifting stations. The internal processing of the system consists of four steps: “Cake Formation,” “Filtration,” “Regeneration,” and “Sludge Treatment.”

Request for a quote

F.E.S. GMBH

Germany

Hinged belt filters, also known as folding belt filters, are used for cleaning contaminated coolant fluids in metal processing and rolling mill applications. Cleaned coolant fluids have longer service life, improve the surface quality of workpieces or rolled goods, and assist in heat dissipation at the processing or forming site. Advantages: High throughput capacity No backflushing required during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure flushing system Cost-effective Operation: The F.E.S. hinged belt filter incorporates a circulating plastic filter belt to meet the filtration requirements without disposal issues. A filter belt cleaning device is located below the filtrate discharge chamber. The opening and closing of the chambers are controlled by two pneumatic cylinders. The self-locking toggle lever mechanism keeps the chambers closed even in the event of a loss of compressed air.

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

CPC EUROPA GMBH

Germany

Better insulation and high heat dissipation capacity Compact enclosure design for high power density Y-shape/construction for high rigidity — Product for high travel speeds and high precision. — High rigidity with direct drive in closed loop, combined with high accuracy. — High efficiency — The linear motor can be used within clean environments — No pitch error and backlash — Very quiet even at high and low travel speeds — No lubrication required — Very suitable for use in clean rooms — Easy to create systems with multiple motors Magnetic track

Request for a quote

CPC EUROPA GMBH

Germany

— Superior electrical insulation and heat dissipation capability — Compact package with high force output — beam design for excellent structural integrity and strength High speed and high precision High-rigidity direct drive coupled with closed-loop control system enables precision control to attain high speed operations with excellent precision performances. In addition, the ironless linear motors are stable and smooth when operated at low speeds. Simple mechanical structure Multiple forcers, each operated individually, can be installed on a single magnetic way to form a simple overall structure that can be readily assembled. For high cleanness requirement applications The linear motor series offer solutions to dirt buildup and lubricant spray mist problems associated with conventional transmission structures containing gear gaps and ball screws. Hence this series is ideal for applications in dust-free environments.

Request for a quote

BERNSTEIN AG

Germany

The CC-3000 light-duty operating enclosure is particularly suitable for encapsulating operator control panels, industrial computers and display components and, thanks to its modular concept, can be simply adapted to versions tailored to specific customer requirements. — Customised solutions to your specifications — Monitor-based industrial design — Freely selectable width and height (max. 600 x 600 mm) — Depths from 120 mm up to max. 255 mm — High-quality extruded aluminium sections (naturally anodised) — Customised colours from RAL range — Five possible enclosure designs — Optimum heat dissipation due to aluminium sections — Front panels internally-mounted or externally-mounted — Protection class IP65 — Screw-fixed or hinged rear panel — Internal grooves for fixing components — Extensive range of accessories

Request for a quote

BERNSTEIN AG

Germany

The aluminium control enclosure CC-5000 neXt offers a unique design with a number of accessories such as the status light. The rounded contours ensure the enclosure is highly recognisable in machinery and mechanical engineering applications. — Customised solutions to your specifications — Innovative and modern industrial design — Freely selectable width and height (max. 1.000 x 1.000 mm) — Depths from 75 mm up to max. 370 mm — Rounded edges, no risk of physical injury — High-quality extruded aluminium sections (naturally anodised) — Customised colours from RAL range — Optimum heat dissipation due to aluminium sections — Integrated recessed grips for simple handling — Protection class IP65 — Internally-mounted front panel — Door configurations for direct access to the interior — Slimline design for configuring flat screen systems

Request for a quote

BERNSTEIN AG

Germany

The CC-4000 / CC-4000 SL are modular aluminium control enclosure systems. With their outstanding technical features, the enclosures simply and efficiently encapsulate industrial controllers and operator control panels for centralised and decentralised automation in production processes. — Customised solutions to your specifications — Simple and modern industrial design — Freely selectable width and height (max. 800 x 800 mm) — Depths from 52 mm up to max. 646 mm — High-quality extruded aluminium sections (naturally anodised) — Coloured areas that emphasize the design — Optimum heat dissipation due to aluminium sections — Integrated handle elements with vertical section — Protection class IP65 — Front panels internally-mounted or externally-mounted — Internal grooves for fixing components — Product features SL (in addition to CC-4000) - Two enclosure depths (55 und 99 mm) - Slimline design - For encapsulating flat IPCs

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Our gwk engineers are passionate about developing technical solutions and this is what we as manufacturers want to prove in the area of cooling towers with our gvk/ghkv series. We see it as our task to understand the entire process of our customers. Therefore we have focused on quality and longevity for the products gvk/ghkv. The cooling towers are part of a central cooling tower system, supplied turn-key and regulated with a freely programmable microprocessor control system or programmable logic control. They are used for dissipation of excess heat from production systems with a higher temperature level and they operate on the principle of evaporation. This is an important consideration for environmentally conscious industries.

Request for a quote

JINTIAN COPPER

Germany

Main products: Copper tubes for air conditioning and refrigeration, inner grooved copper tubes, environmentally friendly copper water (gas) tubes, insulation tubes, tube fittings, plastic-coated tubes Product characteristics: High dimensional precision, high heat dissipation performance, high cleanliness, lightweight Applications: Air conditioning, refrigeration, automotive industry, construction industry, home appliances Production capacity: 150,000 tons Honorary titles: Second Prize of Science and Technology Award of China Nonferrous Metals Industry, Second Prize of Science and Technology of Zhejiang Province

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

pink low tribocharging and dissipative LDPE tubing heat sealable with ESD standard print several thicknesses and widths available on request

Request for a quoteResults for

Heat dissipators - Import exportNumber of results

51 ProductsCountries

Company type

Category

- Industrial equipment hire (5)

- Posters - advertising management (4)

- Control panels - electric (3)

- Industrial tools (3)

- Display boards and screens, electronic (2)

- Aluminium sheets and bands (2)

- Cameras, cinematographic (2)

- Electrical & Electronic Components (2)

- Electrical components and parts (2)

- Engines & Parts (2)

- Industrial cutting machine tools (2)

- Tapes, adhesive (1)

- Copper wires and cables (1)

- Design and production of advertising campaigns (1)

- Elements, electric (1)

- Entertainment and performance - production (1)

- Grinding - steels and metals (1)

- Heating and air conditioning - works (1)

- Heating, domestic - installations and equipment (1)

- Industrial piping (1)