- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ventilators

Results for

Ventilators - Import export

BLOWERDOOR GMBH

Germany

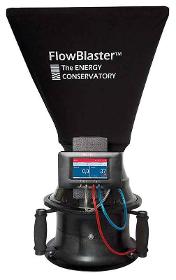

With a measuring range of 17 to 500 m³/h, the Minneapolis FlowBlaster has been especially designed for testing ventilation systems during residential and commercial construction. In combination with the measuring fan BlowerDoor MiniFan, it allows the precise measurement of the air flow at supply and exhaust air valves. Measuring the supply and exhaust air flow at the respective valves provides information as to whether the requirements have been implemented as designed. If the air flows measured at the valves deviate from the requirements, the ventilation system can be adjusted.

Request for a quote

BLOWERDOOR GMBH

Germany

The Minneapolis Micro Leakage Meter (MLM) Measuring System has been developed by the manufacturer The Energy Conservatory in close cooperation with BlowerDoor GmbH in order to guarantee the functionality of ventilation systems by conducting airtightness tests of the duct system. With a measuring range of 0.17 to 78.5 m³/h, the MLM is also suitable for testing building components as well as small and highly airtight clean rooms.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The BEV-G is a single-stage valve offering only the function of the first ventilation stage (coarse ventilation) provided by the two-stage valve (BEV-GF). It is not necessary to coordinate the valve to the working pressure in the first ventilation stage, since coarse ventilation is always closed under pressure. Type G (coarse ventilation): The air escapes through this valve until the medium closes it as it continues to flow. The valve remains closed under operating pressure. Ventilation of individual sections in sloped pressure lines, especially as a low pressure safety feature Quick ventilation of high points if fine ventilation is not required (short pump run times)

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The BEV-F is a single-stage valve offering only the function of the second ventilation stage (fine ventilation) provided by the two-stage valve (BEV-GF). For ventilation quantities of 20 to 40 m3/h. Specific applications include high points which are under hydrostatic pressure even when the pump is shut down due to the height variation involved, and where no coarse ventilation is required, as well as at high points with low flow quantities. Type F (fine ventilation): Air escapes through this valve, and collected gases cause it to open once again, including under operating pressure, until the medium continues to flow and close the valve again. Installed at high points which are under hydrostatic pressure even when the pump is shut down due to the height variation involved, and where no coarse ventilation is required. Installed at high points of pressure lines with low flow quantities.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWAaerob 110 - 1700 ventilation system consists of an oil-free compressor with noise suppressor, a switching system with operating hours counter and a timer, as well as a complete connection fittings set with manometer, check valve and connection line. The ventilation quantity and duration are adjusted by the timer based on the compressor run time. Fine pearls of oxygen are injected from the air. Ideal for short pressure pipes and high flow speeds in the pressure pipe Area of application for pressure pipes <= DN 200 Use with or without accompanying pipe (depending on the high and low points in the pressure pipe)

Request for a quote

KITO ARMATUREN GMBH

Germany

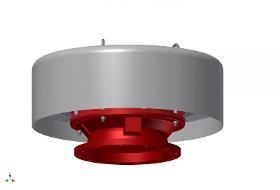

Application as breather/venting safety device incorporating an explosion proof flame arrester element for installation on top of storage tanks, tank access covers or breather pipes. The breather allows the unimpeded flow of gases out to atmosphere and air into the tank/pipe thereby preventing vacuum locks whilst ensuring provision of a permanent and reliable protection against any flashback into the tank/pipe. This device is not permitted to be installed in enclosed areas. Approved for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a maximum operating temperature of 60 °C .

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as end-of-line armature for venting apertures on tank installations. Tested and approved against atmospheric deflagrations for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a maximum operating temperature of 60 °C. Used mainly as venting and breather device for fixed roof tanks. Used to prevent inadmissible pressure and vacuum and to minimize unwelcome gas losses or inadmissible emissions respectively. The housing is mounted perpendicularly on a tank roof. Available with an explosion and endurance burning proofed condensate drain device.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as installation explosion-proof and endurance burning proof for certain flammable liquids of the explosion group IIA with a maximum experimental safe gap (MESG) > 0.9 mm and a maximum operating temperature of 60 °C. As venting and breather device for fixed roof tanks to prevent inadmissible pressure and vacuum and to minimize gas losses by variable pressure setting of the weight-loaded and/or spring-loaded valve devices. Installation of an explosion-proof condensate drain device is possible.

Request for a quote

KITO ARMATUREN GMBH

Germany

Proof for products of explosion group IIA with a maximum experimental safe gap (MESG) > 0.9 mm and a maximum operating temperature of 60 °C. Mainly used as equipment of fixed roof tanks for venting and inbreathing to prevent undue pressure resp. vacuum and undesired losses of vaporization, respectively undue emissions. Installation on top of storage vessels. Available with an explosion and endurance burning proofed condensate drain device.

Request for a quote

KITO ARMATUREN GMBH

Germany

As breather/venting safety device incorporating an explosion proof flame arrester element for installation on top of storage tanks, tank access covers or breather pipes. The breather allows the unimpeded flow of gases out to atmosphere and air into the tank/pipe thereby preventing vacuum locks whilst ensuring provision of a permanent and reliable protection against any flashback into the tank/pipe. This device is not permitted to be installed in enclosed areas. Approved for all materials of the explosion group IIB3 with a maximum experi-mental safe gap (MESG) ≥ 0.65 mm and an maximum operating temperature of 60 °C .

Request for a quote

KITO ARMATUREN GMBH

Germany

As end-of-line armature, for venting apertures on tank installations. Used mainly as venting and breather device for fixed roof tanks. Used to prevent inadmissible pressure and vacuum and to minimize unwelcome gas losses or inadmissible emissions respectively. The housing is mounted perpendicularly on a tank roof.

Request for a quote

KITO ARMATUREN GMBH

Germany

For installation into pipes to the protection of vessels and components against deflagration of flammable liquids and gases. Approved for all substances of explosion groups IIA1 to IIA with a maximum experimental safe gap (MESG) > 0.9 mm. Bi-directionally working in pipes, whereby an operating pressure of 1.2 bar abs. and an operating temperature of 60 °C must not be exceeded. The distance between a potential ignition source and the flame arrester must not exceed 50 times the inner pipe diameter. The installation of the Deflagration flame arrester into horizontal and vertical pipes is permissible. When equipped with one or two temperature sensors, the devices are protected under atmospheric conditions against a short time burning by a burning time tBT = 1.0 min. If only one temperature sensor, then it is to be placed on the device side where a burning could be expected.

Request for a quote

KITO ARMATUREN GMBH

Germany

Explosion proof safety valve to protect inbreathing openings of storage tanks, vessels and pipes to prevent inordinate vacuum. Approved for flammable liquids of explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a Maximum operating temperature of 60 °C.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as end-of-line armature for venting and breathing of tanks. Tested and approved against atmospheric deflagrations for all materials of the explosion group IIB3 with a maximum experimental safe gap (MESG) ≥ 0.65 mm and a maximum operating temperature of 60 °C. Vertical mounting (for tank roofs) with an integrated elbow as an option.

Request for a quote

KITO ARMATUREN GMBH

Germany

Application as end-of-line armature for venting apertures on tank installations, valve is explosion-proof and endurance-burning proof for certain inflammable liquids. Used mainly as venting and breather device for fixed roof tanks to prevent inadmissible pressure and vacuum and to minimize unwelcome gas losses and inadmissible emissions. Approved for all materials of the explosion group IIA with a maximum experimental safe gap (MESG) > 0.9 and a maximum operating temperature of 60 °C. The housing is mounted perpendicularly on a tank roof. If required by the customer, the valve is equipped with an explosion-proof condensate drain device.

Request for a quote

KITO ARMATUREN GMBH

Germany

As end-of-line armature, for venting apertures on tank installations. Used mainly as venting and breather device for fixed roof tanks. Used to prevent inadmissible pressure and vacuum and to minimize unwelcome gas losses or inadmissible emissions respectively. The housing is mounted perpendicularly on a tank roof. The product vapours can be discharged through a collective line into the atmosphere connected to the line flange on the pressure side.

Request for a quote

KITO ARMATUREN GMBH

Germany

As emergency venting device for installation on storage tanks with a VRV to protect against hazardous excess pressure but minimize the loss of gas/vapours. Also suitable as replacement of a manhole. This device does not protect against the hazard of explosion or stabilized burning.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAMPMANN GMBH & CO. KG

Germany

Product advantages — hygiene-compliant in accordance with VDI 6022 in conjunction with optional ePM10 >50% filter — market-leading quiet and nevertheless enormous outputs, at high speed ranges — short delivery times — easy to install — fully automatic KaControl or connection to an existing, external building automation system — customisation for projects and customers, even small quantities - wide range of options Clean air with H14 Hepa filter The adjustable Venkon Hepa filter box can be used to switch the Venkon to air cleaning mode in which 99.995 % all viruses, bacteria, germs and aerosols are drawn out of the air. The great benefit is that this can be done on demand. Create space Concealed in shallow ceilings or wall-voids or exposed with space-saving aesthetically designed casings, we create your special solution. Field of application Hotels, office buildings, retail chains and sales floors.

Request for a quote

KAMPMANN GMBH & CO. KG

Germany

Ultra – For greater energy efficiency The Ultra EC is now equipped with the most energy-efficient drive concept, through the use of EC technology, and can now be used wherever energy needs to be saved over the long term. How it works Air is drawn in through the axial fan and is blown through the circular heat exchanger into the room. The heated or cooled air is guided into the room on-demand through the pre(settable) louvre slats. Benefits —high-performance, energy-saving —suitable for low water temperatures —hygiene-certified to VDI 6022 Applications Buildings of all kinds, which need to be ideally heated and ventilated with centralised or decentralised control. Kampmann is completely modernising its unit heaters. We are responsibly taking a courageous step forwards and, from now on, will be relying systematically on EC technology to power and control our units. The reasons: — No wasted power — Minimum noise levels — ErP-compliant future

Request for a quote

KAMPMANN GMBH & CO. KG

Germany

Trench heating unit with EC tangential fan convection. All-purpose, individual, made-to-measure. The Katherm QK is whisper-quiet. It is also available in 120 versions. It comes in non-standard lengths, with curved trench, mitres, cut-outs for columns or angles. Its ultra-long EC fan covers the entire heating range, from full space heating to cold air screening. Benefits - made-to-measure trench lengths - high outputs at small trench depths, even when used with low temperatures - whisper-quiet EC technology Applications All areas of buildings in which effective heating and cold air screening is required. Effective, energy-saving heating can be provided by Katherm QK in conjunction with modern heating systems

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

Universal pressure transmitter Features: Stainless steel case, degree of protection IP 65 Direct ventilated sensor element Measuring ranges: 0…100 mbar to 0…400 bar rel.; 0…1 bar to 0…6 bar abs. Accuracy ≤ 0.2 % Further features Options: Approvals/Certificates: Certificate of measuring equipment for Russian Federation; Material certificate as per EN 10204-3.1; Calibration certificate as per EN 10204-3.1 Degree of protection IP 67

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

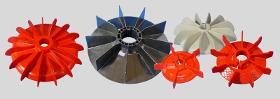

Ventilation fans made of plastic and die-cast aluminium are available with keyway or with clamping device .

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

Unidirectional ventilation fans with a diameter of 250 mm to 2745 mm. Pinhole to be made according to customer´s requirements. Ventilation fans available in either glass-fibre reinforced plastic or aluminium; application temperature – 40 °C to 110 °C and up to 150 °C with aluminium (245°C *).

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

This forced ventilation series offers a wide voltage range of 400 to 575 Volt three-phase in IP 66 Made in Europe. Forced vent. - Motor optionally available in three versions. Mb 1F for standard forced ventilation with drive motor in aluminium, in IP66, insul. Class F. Mb 1G for all special versions, drive motor in cast iron, IP66. Special versions further available in insul. Class H, IP67, special voltage etc. Mb 1H with UL/CSA certified drive motor in aluminium, IP66, insul. Class F.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

The main characteristics of the forced ventilation unit are short assembling measures. The ventilations are static and dynamically balanced, thus, of a high balance quality. The diameter, the length as well as the side punchings can be made to customer´s requirements.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

Forced Ventilation Units Forced Ventilation Units type MW in IP 66 with axial ventilation fan to ensure a low run at a simultaneously higher output. These units can be operated at a higher ambient temperature of max. 60 °C.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

This forced ventilation series offers a wide voltage range of 220 to 275 (+-5%) Volt single-phase respectively 380 to 480 (+-5%)Volt three-phase in protection class IP 66 The very high stiffness and stability in connection with our flexible assembly possibilities for the extensions and the wide electric field of application offers you a cost-effective, technically high-quality solution for your motors .

Request for a quoteResults for

Ventilators - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Valves for pneumatic equipment (11)

- Water - production and distribution (3)

- Measurement - Equipment & Instruments (2)

- Air conditioning, aeration and ventilation equipment (1)

- Air conditioning equipment (1)

- Heating, industrial - installations and equipment (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Petrochemical industry - installations and equipment (1)

- Plumbing, industrial (1)

- Unit heaters (1)