- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spherical rollers

Results for

Spherical rollers - Import export

GURTEC GMBH

Germany

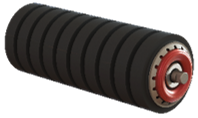

Impact rollers are available with rubber or polyurethane discs FRAS discs are available for explosive environments Dimensions: Roller diameter 63,5 mm (2-1/2” to 10”) Shaft diameter up to 80 mm (3-1/8”) Ball and spherical roller bearings

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Double row spherical roller bearings have two rows of self-aligning rollers and common spherical raceways on the outer ring. The internal construction of the bearing enables the mirrored misalignment of the rings. Spherical roller bearings can tolerate high radial loads whilst at the same time transmitting axial forces in both directions.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Bearings in these applications are subjected to very severe operating conditions. The shaking actions of vibrating equipment subjects the bearings to very heavy loads, including impact loads. Additional load is created by higher g forces generated by acceleration in the application. Bearings are higher speed operated. Furthermore, these kinds of bearings are developed to increase the lifetime of bearings in contaminated environments. KFB designs special spherical roller bearings MAC4F80 to operate under severe conditions. Special KFB spherical roller bearings for vibrating equipment are available in 22300 and 23300 series. The clearance is similar to C4, but the lower third of C4 range is eliminated for better control of the bearing clearance after mounting.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

In the mining sector severe operating and environmental conditions require extremely robust bearings. Bearings for mining industry are used for bucket wheel excavators, draglines, conveyor belts, trucks, stackers, transport equipment, loaders, longwall shearers and hoists. The mining industries use many types of bearings: roller bearings, deep groove ball bearings, spherical roller bearings and tapered roller bearings. DEEP GROOVE BALL BEARINGS The mining industries use belt conveyors for transporting bulk materials. The conveyors run on idlers and a lot of them extend over many kilometers; thus the number of idlers needed may be very large. The deep groove bearings (design 2ZR and 2RS) are sealed by dust shields and seals on both sides, and filled with grease for a long service life. SPHERICAL ROLLER BEARINGS In the mining sector severe operating and environmental conditions require extremely robust bearings. Mining machinery faces some of the toughest terrains.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

double row cylindrical roller bearings ball bearings spherical roller bearings cylindrical roller bearings specified by UIC double row cylindrical roller bearings standardized by UIC single and double row tapered roller bearings standardized by UIC axle box transmission traction motors B-asymmetrical rollers C-symmetrical rollers R-bearings without inner rings M-machined brass cage, roller centered MA-machined brass cage, outer ring centered TN-injection moulded cage of glass fibre according with ISO 281:2007 W33-annular groove and three lubrication holes P6-according with ISO tolerance class 6 No code-standard C3-greater than standard C4-greater than C3 K-tapered bore ratio 1:12 No code-cylindrical

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

require high precision, large rated moving load, and high maximum rotation speed. By adopting the new technology of material processing, KFB has successfully manufactured bearings of long service life that are highly fatigue resistant and impact resistant. The types of bearings made by KFB for the metallurgical roller mills are: split bearings; unit rollers; support roller bearings; single row, double row, three row, four row cylindrical roller bearings, fully-loaded cylindrical roller bearings, spherical roller bearings. The use of split bearings appreciably facilitates assembly and repair operations compared to the use of nonsplit (conventional) bearings. It does away with the need for the disassembly and subsequent reassembly of intermediate parts and mechanisms, which is required when replacing conventional bearings. It also reduces costs and production losses. If provided with efficient cooling, reliable lubrication and proper sealing, split-bearing components can be used...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Spherical rollers - Import exportNumber of results

6 ProductsCountries

Company type