- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- small series

Results for

Small series - Import export

ING. KURT SCHADE GMBH & CO. KG

Germany

Our steel construction is certified according to the current standards DIN EN 1090-2 and DIN EN 3834-2. We manufacture welded parts, welded constructions and welded assemblies up to execution class 3 (EXC3). Steel construction components such as: - Assembly devices for aircraft or automobile construction - Machine frames for compressor construction - Welded frames such as track systems and transfer tables - High-precision vacuum clamping plates for high-pressure presses - Complete rudder systems We produce both: individual components and small series. Do you have any questions about our techniques, capacities or prices? Contact us, we will be happy to give you direct information.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover the diverse services EWOQE offers for the industry! As a leading B2B partner at the highest level, we utilize 3D printing to revolutionize traditional manufacturing processes. Our expertise ranges from creating 3D models to manufacturing prototypes and small series, all the way to producing final products. Benefit from our knowledge in additive manufacturing and join us in creating innovative products. Whether you need high-quality plastic parts, assistance with design and model making, or customized solutions, we are your reliable partner. Thanks to our modern machinery and years of experience, we consistently deliver high-quality results. Trust EWOQE for your specific requirements in additive manufacturing and contact us today to advance your projects. Our commitment to fast, cost-efficient services and our ability to handle complex design and construction challenges make us an ideal choice for businesses looking to leverage the advantages of 3D printing technology.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover the world of Additive Manufacturing with EWOQE! As a leading B2B partner at the pinnacle of industrial standards, we utilize 3D printing to revolutionize traditional manufacturing methods. Our focus is on producing components with precision and efficiency, not to replace existing production processes but to enhance them. We are convinced of the diverse possibilities that 3D printing offers and view it as an indispensable tool for achieving our goals. Through continuous investments in research and development, we remain at the cutting edge of this technology, always offering our clients innovative solutions. Our range of services includes the creation of 3D models, the manufacturing of prototypes and small series, as well as the production of final products. From high-quality plastic parts to design and model making, we are your reliable partner for all your Additive Manufacturing needs.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover the world of Rapid Prototyping with EWOQE! As a leading B2B partner at the highest industrial level, we use 3D printing to revolutionize traditional manufacturing methods. Our focus is on quickly and precisely manufacturing components, not to replace existing production processes but to complement them. With our deep understanding of the possibilities offered by 3D printing, we provide innovative solutions for complex geometries and customized designs. Through continuous investments in research and development, we remain at the forefront of this technology, always offering our clients top-notch services. Our range of services includes the creation of 3D models, the manufacturing of prototypes and small series, as well as the production of final products. From high-quality plastic parts to design and model making, we are your reliable partner for all your Rapid Prototyping needs.

Request for a quote

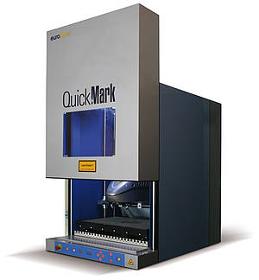

EUROLASER GMBH

Germany

CO2 lasers offer impressive results in the marking of organic and inorganic materials. A very high degree of detailed accuracy and long-lasting markings are the outstanding features of this marker. The compact marking lasers from eurolaser require very little space, operate reliably and accurately and are designed for use in made-to-order items through to small series. It goes without saying that they can also be integrated into production lines.

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

These mobile and manually operated self-piercing systems are primarily used in prototype and small series production or spare parts supply. They also support fall-back options for your production. • Easy positioning on workpieces due to a fixed curved rivet feeder. The stroke is just performed by ram and nosepiece. • Curved rivet feeder 270° turnable, slim ram • Throat options and weight optimisation This offer includes: Eckold self-pierce riveting system, manually operated • Portable C-frame, weight optimisation up to max. 70 kN incl. nosepiece, 2-hand safety release, hose set, turn/swivel device • Drive unit HA-226 incl. frame, pump unit, control cabinet with 12“ touch panel • Rivet magazine Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

If you want to have a device completely assembled, you've come to the right place. It does not matter whether you only need a small number of items or series production. We derive the processes and assembly instructions from a first joint workshop. In this way we can procure the important components, assemble the device and then test it. Your product will be assembled according to your requirements. On request, we can assemble under clean room conditions, assemble only individual components or prepare the device for final assembly on your premises. When assembling devices, we can work with methods such as press-fit technology or, for example, secure components by gluing. Your advantages with A + B Electronic -Device assembly according to your requirements -We are not just a service provider, but a technology partner: A + B Electronic thinks your project with you and together we can bring it to series production successfully

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

Suitable for every order size: SMD assembly is one of our core competencies Our SMD assembly is characterized by modern production standards and a low error rate. Stencil printers and a jet printer are available in front of our three production lines. This means that we are as flexible as possible when preparing your project. The SMD components are precisely applied in our pick and place machines and soldered in reflow ovens, or in special cases also in our vapor phase. A highlight: We have a hybrid assembly machine, the FUJI 7x NXT2. This is our way to work with the greatest precision, quickly and safely. What speaks for us: -Your Contact person for prototypes, large or small series -A high mix of components is not a problem -We test the technical feasibility of your project before each order -We are not just a service provider, but a technology partner: A+B Electronic thinks through your project with you and together we can bring it to successful series production

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

From component preparation to precise soldering and checking: our THT assembly Our skilled employees take care of the manual component preparation on site so that the component later fits perfectly on the circuit board. We also have our own parts warehouse, with which we ensure reliable production of your THT orders. The THT assembly area at A + B Electronic includes three selective soldering systems and two wave soldering systems. Depending on the equipment, the right soldering process is selected. With the Ersa VERSAFLOW 4/55 selective soldering machine, we also have a system of the latest product generation. What speaks for us: -Contact person for prototypes, large or small series -A high mix of components is not a problem -We test the technical feasibility of your project before each order -We are not just a service provider, but a technology partner: A+B Electronic thinks through your project with you and together we can bring it to successful series production

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

At A+B Electronic you receive all services from a single source. In addition to the pure assembly, we are also happy to take care of the coating of your assemblies. The conformal coating serves to protect the surface of the assemblies, e.g. against condensation or contamination. In the process, the paint is applied using a curtain casting process under low pressure. The coating is only applied selectively where it is needed. Here we work with a programmed coordination system that is precisely tailored to your assembly. To dry, the elements are placed in our drying ovens and chambers so that the paint can cure in the atmosphere. What speaks for us: -Contact person for prototypes, large or small series -A high mix of components is not a problem -We are not just a service provider, we are a technology partner: A + B Electronic thinks your project with you and together we can bring it to series production

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Small series - Import exportNumber of results

17 ProductsCountries

Company type