- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller bearing

Results for

Roller bearing - Import export

GURTEC GMBH

Germany

A roller with a solid shaft as standard, hollow shaft as option Bearing seats formed as an integral part of the shell, the opposing bearings are therefore accurately aligned The formed bearing holders improve bearing performance leading to lower failure rates Dimensions: Roller diameters 152 – 219 mm (6” to 8-5/8”) Shaft diameters up to 62 mm (2-1/2”) Bearings 6306, 6308, 6310, 6312

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Single row cylinder roller bearings with retainer are available as loose bearings, support bearings and fixed bearings. In the range of single row cylinder roller bearings are the model types N, NJ, NU and NUP, whereas the model series NN includes the double row cylinder roller bearings.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Tapered roller bearings are composed of solid outer and inner rings with tapered raceways and tapered rollers with cage assembly. The bearings are separable. Therefore, the inner ring with the rollers and the assembly cage can fitted separated from the outer ring. Tapered roller bearings tolerate high radial and one sided axial forces. For axial steadying, a second bearing is usually necessary, which is then fitted mirror-inverted.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Axial needle cage assemblies Axial needle cage assemblies, composed of synthetic or metal axial cage assemblies with integrated needle rollers, have an extremely low overall height. They tolerate high axial forces acting in one direction, radial forces must be taken up separately. The deployment of axial needle cage assemblies requires that hardened and bevelled thrust surfaces may be used as raceways. Thrust bearing washers Thrust bearing washers are punched, hardened and polished and can be used as shaft or housing washers. These washers are appropriate when the adjoining machine part when not hardened, is rigid enough and of a stable form. Axial needle bearings Axial needle bearings are components made up of axial needle rollers and cage assemblies and axial washers with centring bore. They can be combined with needle sleeves, needle bushes and needle bearings. The thrust surface for the cage assembly must be hardened and bevelled. The product types AXK and K are applicable here

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Double row spherical roller bearings have two rows of self-aligning rollers and common spherical raceways on the outer ring. The internal construction of the bearing enables the mirrored misalignment of the rings. Spherical roller bearings can tolerate high radial loads whilst at the same time transmitting axial forces in both directions.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

KFB-Clarfeld thrust ball bearings are manufactured as single and double direction models. Ball bearings of the series 511, 512, 513 and 514 are single sided, the models 522, 523 and 524 are double sided. Thrust ball bearings are composed of shaft washers, cage washers, and cage assemblies. The bearings are separable; cage assembly and bearing washers can therefore be fitted independently of each other. Both models tolerate high axial forces, however, they may not be radially stressed.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Bearings in these applications are subjected to very severe operating conditions. The shaking actions of vibrating equipment subjects the bearings to very heavy loads, including impact loads. Additional load is created by higher g forces generated by acceleration in the application. Bearings are higher speed operated. Furthermore, these kinds of bearings are developed to increase the lifetime of bearings in contaminated environments. KFB designs special spherical roller bearings MAC4F80 to operate under severe conditions. Special KFB spherical roller bearings for vibrating equipment are available in 22300 and 23300 series. The clearance is similar to C4, but the lower third of C4 range is eliminated for better control of the bearing clearance after mounting.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

double row cylindrical roller bearings ball bearings spherical roller bearings cylindrical roller bearings specified by UIC double row cylindrical roller bearings standardized by UIC single and double row tapered roller bearings standardized by UIC axle box transmission traction motors B-asymmetrical rollers C-symmetrical rollers R-bearings without inner rings M-machined brass cage, roller centered MA-machined brass cage, outer ring centered TN-injection moulded cage of glass fibre according with ISO 281:2007 W33-annular groove and three lubrication holes P6-according with ISO tolerance class 6 No code-standard C3-greater than standard C4-greater than C3 K-tapered bore ratio 1:12 No code-cylindrical

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

require high precision, large rated moving load, and high maximum rotation speed. By adopting the new technology of material processing, KFB has successfully manufactured bearings of long service life that are highly fatigue resistant and impact resistant. The types of bearings made by KFB for the metallurgical roller mills are: split bearings; unit rollers; support roller bearings; single row, double row, three row, four row cylindrical roller bearings, fully-loaded cylindrical roller bearings, spherical roller bearings. The use of split bearings appreciably facilitates assembly and repair operations compared to the use of nonsplit (conventional) bearings. It does away with the need for the disassembly and subsequent reassembly of intermediate parts and mechanisms, which is required when replacing conventional bearings. It also reduces costs and production losses. If provided with efficient cooling, reliable lubrication and proper sealing, split-bearing components can be used...

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

In the mining sector severe operating and environmental conditions require extremely robust bearings. Bearings for mining industry are used for bucket wheel excavators, draglines, conveyor belts, trucks, stackers, transport equipment, loaders, longwall shearers and hoists. The mining industries use many types of bearings: roller bearings, deep groove ball bearings, spherical roller bearings and tapered roller bearings. DEEP GROOVE BALL BEARINGS The mining industries use belt conveyors for transporting bulk materials. The conveyors run on idlers and a lot of them extend over many kilometers; thus the number of idlers needed may be very large. The deep groove bearings (design 2ZR and 2RS) are sealed by dust shields and seals on both sides, and filled with grease for a long service life. SPHERICAL ROLLER BEARINGS In the mining sector severe operating and environmental conditions require extremely robust bearings. Mining machinery faces some of the toughest terrains.

Request for a quote

GURTEC GMBH

Germany

Real time laser monitoring Belt width 1400-2200 mm (55” to 87”) See more >

Request for a quote

GURTEC GMBH

Germany

Hydraulic operated Rotational speed of brush: max. 150 RPM Can be adjusted by hydraulic pump – brush will be lifted to operation position by hydraulic cylinder and keep same pressure against the belt

Request for a quote

GURTEC GMBH

Germany

increases friction between the belt and the surface of the pulley improves efficiency and guidance helps prevent material building up on the surface of the pulley protects the shell of the pulley from wear provides a wear surface that can be replaced economically Lagging materials for drive and non-driven pulleys: HP142 – Hot vulcanized rubber lagging HP144 – Cold bonded rubber lagging HP145 – Hot vulcanised ceramic lagging HP146 – Cold bonded ceramic lagging HP147 – Hot cast urethane lagging HP148 – Cold bonded urethane lagging HP149 – Direct bonded ceramic lagging

Request for a quote

GURTEC GMBH

Germany

Available as either standard Catalogue Product Range or as application specific designs. Pulley Diameters up to 2,600 mm (102”) Belt widths up to 3,500 mm (138”) Shaft diameters up to 600 mm (24”) Available in many configurations, welded and T-shaped end discs for especially demanding applications Individually designed solution with state-of-the-art design software, custom built for best performance, service life and operating economy Offers a low total life-time cost We have manufactured extra heavy duty pulleys with up to 2,600 mm (102”) diameter and 45 tonnes in weight (99,000 lb)

Request for a quote

GURTEC GMBH

Germany

Available as either standard catalogue product range (up to bearing size 360 mm (14”) or as application specific designs. Pulley Diameters up to 1,250 mm (49”) Belt widths up to 3,500 mm (138”) Shaft diameters from 100 to 400 mm (4″ to 16″) Locking elements sized to handle bending moment and torque Construction includes both welded end discs & T-shaped end discs Weight optimized design Ceramic/rubber lagging options available

Request for a quote

GURTEC GMBH

Germany

Standard Catalogue Product Range Pulley Diameters up to 800mm (32”) Belt widths up to 2,800mm (110”)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GURTEC GMBH

Germany

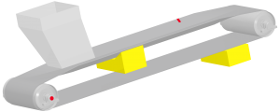

Our garland rollers are connected to each other with flexible links and fixed to the conveyor frame with suspension links Free movement in the direction of the belt travel has also a positive influence on the self-centering of the belt easy to replace by lifting the idler set from the mounting hook

Request for a quote

GURTEC GMBH

Germany

Positive action training frames in all configurations Side guide rollers orientate the frame and help ensure the belt tracks centrally on the conveyor Dimensions: Available in all configurations for both carry and return frames Positive action helps keep the belt aligned with the center of the conveyor

Request for a quote

GURTEC GMBH

Germany

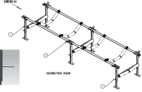

Development structure is available from 1,050 to 1,400 mm (42” to 55”) Maingate structure is available from 1,400 – 2,000 mm (55” to 78”) Supplied complete with garland or fixed frame idlers Suitable for floor or roof mounting Dimensions: Available as development and maingate structure Belt widths from 1,050 – 2,000 mm (42” to 78”)

Request for a quote

GURTEC GMBH

Germany

Includes flat return and multi-roll vee returns Dimensions: Available is single roll, 2, 3, 4 or 5 roll configurations Belt widths from 350 to 3,500 mm (14” to 138”)

Request for a quote

GURTEC GMBH

Germany

Jackdown frames in 3, 5, 6 or 10 roll arrangements Retractable frames Other special loading frames available – for example impact roller cassettes Dimensions: Includes Jackdown, retractable and other special impact arrangements Belt widths from 350 to 3,500 mm (14” to 138”) Various trough angles available

Request for a quote

GURTEC GMBH

Germany

Trough or flat carry frames available (including transition frames) Combinations range from single roll to 5 roll designs Dimensions: Belt widths from 350 to 3,500 mm (14” to 138”) Various trough angles available

Request for a quote

GURTEC GMBH

Germany

Available as frames only or fitted with rollers as idlers We supply trough carry, impact, training, and disc return fixed frames in a wide range of sizes for belt widths from 350 mm to 3,500 mm (14″ to 138″) Frames are either galvanized or with a painted surface finish All our frames provide minimal gaps between rollers and are designed to counteract material build-up Our frames are designed to maintain an optimum conveyor belt profile for low rolling resistance, excellent belt support, good belt guidance and long belt life

Request for a quote

GURTEC GMBH

Germany

A flow formed roller shell and hollow formed shaft Option for an increased wall thickness at the middle of the shell for reduced shell deformation and increased fatigue life Extremely low TIR with a accurate and constant shell thickness significantly reduces vibration and increases service life Dimensions: Roller diameters 159 – 219 mm (6-1/4” to 8-5/8”) Shaft diameters up to 82 mm (3-1/4”) Bearings 6308, 6310, 6312

Request for a quote

GURTEC GMBH

Germany

GURTEC’s Heavy Mining Idler Roller is setting a new standard for high speed mass transportation and life cycle costs. Our highly automated manufacturing line utilises a flow forming process for extremely round tubes and an end forming process to round shell edges and integrate concentric bearing houses to the roller shell body, avoiding the need for welding.

Request for a quote

GURTEC GMBH

Germany

The composite roller is up to 60% lighter than an equivalent steel roller Available with composite, aluminium and steel shell materials At R&D stage Dimensions: Composite, aluminium and steel shells Roller diameter 152 -178 mm (6” to 7”) Shaft diameter up to 60 mm (2-3/8”) Bearing 6306, 6307, 6308, 6309, 6310

Request for a quote

GURTEC GMBH

Germany

Aluminium rollers are ideal for harsh corrosive environments The light weight also provides EHS benefits during installation and replacement Dimensions: Roller diameter 127-152 mm (5” to 6”) Shaft diameter up to 60 mm (2-3/8”) Bearing 6205, 6305, 6307, 6308, 6309

Request for a quote

GURTEC GMBH

Germany

Excellent roundness and balance reduces vibration and ensures quiet operation and extended roller life Dimensions: Roller diameter 127-194 mm (5 to 7-5/8”) Shaft diameter up to 60 mm (2-3/8”) Bearing 6305, 6306, 6307, 6308, 6309, 6310

Request for a quoteResults for

Roller bearing - Import exportNumber of results

47 ProductsCountries

Company type