- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- assemblies

Results for

Assemblies - Import export

ING. KURT SCHADE GMBH & CO. KG

Germany

With the complete assembly of assemblies, we offer you an all-round package: - We buy all the materials you need. - We straighten, staple and MIG MAG weld the individual steel construction components exactly according to your specifications and complete the components using high-precision CNC machining. - We assemble the finished, repeatedly tested components in our 2000 square meter assembly hall according to your construction plans into ready-to-install modules. - We check the final assembly down to the smallest detail. - We deliver the finished end product to you. Are you looking for a reliable service provider to implement your next project? We look forward to your inquiry.

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R40 ✅ Industrial robot applications for components up to 1 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R80 ✅ Industrial robot applications for components up to 2 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities for you. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R15 ✅ Industrial robot applications for components up to 8 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

If you want to have a device completely assembled, you've come to the right place. It does not matter whether you only need a small number of items or series production. We derive the processes and assembly instructions from a first joint workshop. In this way we can procure the important components, assemble the device and then test it. Your product will be assembled according to your requirements. On request, we can assemble under clean room conditions, assemble only individual components or prepare the device for final assembly on your premises. When assembling devices, we can work with methods such as press-fit technology or, for example, secure components by gluing. Your advantages with A + B Electronic -Device assembly according to your requirements -We are not just a service provider, but a technology partner: A + B Electronic thinks your project with you and together we can bring it to series production successfully

Request for a quote

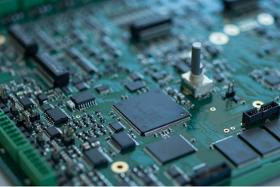

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

Suitable for every order size: SMD assembly is one of our core competencies Our SMD assembly is characterized by modern production standards and a low error rate. Stencil printers and a jet printer are available in front of our three production lines. This means that we are as flexible as possible when preparing your project. The SMD components are precisely applied in our pick and place machines and soldered in reflow ovens, or in special cases also in our vapor phase. A highlight: We have a hybrid assembly machine, the FUJI 7x NXT2. This is our way to work with the greatest precision, quickly and safely. What speaks for us: -Your Contact person for prototypes, large or small series -A high mix of components is not a problem -We test the technical feasibility of your project before each order -We are not just a service provider, but a technology partner: A+B Electronic thinks through your project with you and together we can bring it to successful series production

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

Two modern AOI devices (automatic optical inspection) in 2D and 3D secure the manufacturing process during the SMT assembly. We use our X-ray inspection device to control the soldering process on components with connections under the housing. In addition to quality assurance, we also offer test and inspection procedures that are precisely tailored to your needs. In addition to circuit-specific in-circuit and burn-in tests, we can carry out application-related function tests in our test field. For specific tests, many customers send us the test procedures with the appropriate equipment directly. In this way we can check the functionality of your assembly without you having to tell us what exactly the tests are checking. Your advantages with A + B Electronic -Test procedures tailored to your needs -We are not just a service provider, we are a technology partner: A + B Electronic thinks your project with you and together we can successfully bring it into series production

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

From component preparation to precise soldering and checking: our THT assembly Our skilled employees take care of the manual component preparation on site so that the component later fits perfectly on the circuit board. We also have our own parts warehouse, with which we ensure reliable production of your THT orders. The THT assembly area at A + B Electronic includes three selective soldering systems and two wave soldering systems. Depending on the equipment, the right soldering process is selected. With the Ersa VERSAFLOW 4/55 selective soldering machine, we also have a system of the latest product generation. What speaks for us: -Contact person for prototypes, large or small series -A high mix of components is not a problem -We test the technical feasibility of your project before each order -We are not just a service provider, but a technology partner: A+B Electronic thinks through your project with you and together we can bring it to successful series production

Request for a quote

BAUKAT GMBH & CO. KG

Germany

New!!! Mercedes Benz Transmission control units A000270260080 We sell ex-works Hemmingen 600 – 700,00 Euro – Parts is on stock! Our products is Genuine Parts in original boxing, don’t hesitate to contact us anytime!

Request for a quoteResults for

Assemblies - Import exportNumber of results

11 ProductsCountries

Company type