- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical assembly

Results for

Mechanical assembly - Import export

ZEMO VERTRIEBS GMBH

Germany

Preset Cam-Over Torque Screwdrivers Mountz FG-IFR (Impact Free Resetting) preset screwdrivers use a cam-over mechanism to improve process control and productivity. The unique IFR cam over design provides a low-impact reset mechanism, ideal for assembling shock-sensitive components that reduce the vibration transmitted in the screw tightening process – ideal for fastening delicate parts such as electronics, plastics, and medical devices. Torque range suitable for micro, low, and medium torque applications. Cam-over technology reduces the possibility of operator error in the clockwise fastening direction, ensuring correct torque is applied and preventing fastener breakage. Providing the operator with a preset tool prevents tampering and ensures that operators always use the appropriate torque setting. A preset screwdriver doesn't have an external torque adjustment scale. The locking mechanism prevents accidental torque setting changes. [...]

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Overhead cooling units for rail bound vehicles Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Assembly Test run Documentation

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Components for testing equipment Welding Mechanical engineering Surface treatment Precision assembly in the µm range at FMS’ facilities Assembly at the end client’s facilities

Request for a quote

METZEN INDUSTRIES GMBH

Germany

The machine is manufactured in FMS’ production facilities and assembled at the end client’s site, including Mechanical and control systems design Procurement of standard and DIN parts Welding Mechanical engineering Surface treatment Internal assembly Test run at FMS’ facilities Assembly including hydraulics, pneumatics and electronics Control systems

Request for a quote

METZEN INDUSTRIES GMBH

Germany

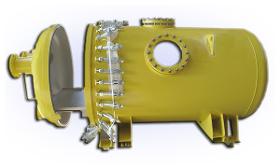

As the NW 400 sight glasses required for the vessel were not standard, an exceptional 3.2 inspection needed to be carried out for them. FMS created a suitable testing fixture for this inspection and then successfully carried out a type examination together with the Technical Inspection Association (TÜV). Design/planning Preparation of pre-test documents for the TÜV Procurement of all materials Pressure and burst tests for the sight glasses Welding Mechanical engineering Surface treatment Fully assembly TÜV acceptance of the pressure and leak test (using SF6 gas) Documentation and acceptance

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Mechanical assembly - Import exportNumber of results

5 ProductsCountries

Company type