- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding discs

Results for

Grinding discs - Import export

RHODIUS ABRASIVES GMBH

Germany

High-performance grinding disc offering superior stock removal, good service life and a good price-performance ratio. • Pleasant grinding behaviour • Long lifetime • High stock removal performance

RHODIUS ABRASIVES GMBH

Germany

Special technologies: Very innovative products with unique problem solving competence. The FS1 FUSION combines the fine surface finish of a flap disc with the durability of a grinding disc. • Ideal for fillet weld grinding • Economic alternative to flap discs • Free choice of grit (40/60/80)

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. High-performance stainless steel rough grinding disc with ceramic abrasive grain. Also performs very well on steel and cast iron. • High stock removal performance • Additional fabric flange from 180 mm for high-frequency and air grinders • Safe thanks to three full-face fabric layers

RHODIUS ABRASIVES GMBH

Germany

Rough grinding disc for the cost-conscious professional, offering easy grinding and good service life. Ideal for low-power machines. • Pleasant grinding behaviour • Good stock removal • Long service life

RHODIUS ABRASIVES GMBH

Germany

Grinding disc with special filler materials prevents clogging while ensuring efficient and continuous grinding. • High stock removal performance • No clogging of the disc • Minimum material heating

RHODIUS ABRASIVES GMBH

Germany

High-performance grinding disc with high bond strength for a long lifetime and powerful material abrasion. • Ideal for powerful work on steel and cast-iron • Additional fabric flange from 180 mm for high-frequency and air grinders • Safe thanks to three full-face fabric layers

RHODIUS ABRASIVES GMBH

Germany

Versatile rough grinding disc. Thanks to the high stock removal performance the RS2 grinds efficiently and with good service life. • Especially good for working on hard materials • High stock removal performance • Long lifetime

RHODIUS ABRASIVES GMBH

Germany

Grinding disc with extra fabric flange for high-frequency or air grinders, offering superior stock removal, good service life. • Especially safe through additional fabric • High stock removal performance • Good lifetime

RHODIUS ABRASIVES GMBH

Germany

Industry-standard disc for the cost-conscious professional, offering easy grinding and good service life. Ideal for low-power machines. • Pleasant grinding behaviour • Good stock removal • Long lifetime

RHODIUS ABRASIVES GMBH

Germany

Grinding disc for stone and also processing of grey cast iron and titanium. • Long service life • Good stock removal performance • Aggressive grinding

RHODIUS ABRASIVES GMBH

Germany

Less force required, offering a long lifetime and superior stock removal. • High stock removal performance • Long lifetime • Pleasant grinding behaviour

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The FAPI-ATTACK sanding disc is ideal for extremely aggressive sanding work and is primarily used for aggressive sanding on the surface as well as on the edge. We would be pleased to advise you on which grinding disk can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs from the FAPI-TRIM series are the ideal tool for deburring on automatic deburring machines (e.g. Weber deburring machines) and are particularly suitable for processing larger series. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs of the FAPI-250 series are the ideal tool for deburring on automatic deburring machines (e.g. Loewer DiscMaster 4TD) and are particularly suitable for processing larger series. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring grinding discs of the FAPI-150 series are the ideal tool for deburring on automatic and manual deburring machines (e.g. our deburring machine FAPI-STARGRINDER) and are particularly suitable for processing larger series. The 25 mm bore and 4 driver holes enable easy assembly and positioning of the FAPI-150 deburring grinding disk on the deburring machine. We would be pleased to advise you on which deburring discs can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With our velcro supporters FAPI-M14, FAPI-TRIM, FAPI-150 and FAPI-250 you can mount all kinds of velcro-backed grinding discs easily. Due to the different mountings and diameter they are usable for many purposes. On handmachines as well as on stationary grinding and deburring machines. Dimensions Diameter: 115 mm / 150 mm / 250 mm Mountings: M14 thread (115 mm) Quick-release system/TRIM (115 mm) Quick-release system/FIT (150 mm) 25 mm hole (150 mm) 30 mm hole (250 mm) We would be pleased to advise you on which velcro supporter can be used in your processing, in order to achieve top process results.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The expander discs FAPI-PA are an optimal grinding tool for working with all types of sanding sleeves. The expander discs are exclusively provided with a specially slotted NBR coating, which means that the sanding sleeve is tensioned by centrifugal force during the processing process. In practice, the expander discs coated with the material NBR are often simply called “rubber expander discs” or also grinding sleeve carriers.Advantages of expander discs with pararubber coating: - Wear resistance - Oil resistance - Grease resistance - Emulsion resistance We would be pleased to advise you on which expander rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RHODIUS ABRASIVES GMBH

Germany

Semi-flexible grinding disc for use on the matching RH ST backing pad. • For processing steel • Especially long lifetime • Combines the benefits of fibre discs and grinding discs

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Ceramic grain fibre disc for the quick change system – the grain enables rapid and superior stock removal performance. • Especially suitable for hardened and tempered steels, tinder areas and titanium • Perceivably faster stock removal • Quick tool change without bonding or sliding

RHODIUS ABRASIVES GMBH

Germany

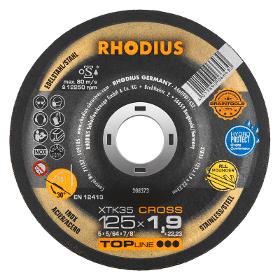

Special technologies: Very innovative products with unique problem solving competence. Abrasive discs with patented HydroProtect technology to safeguard against moisture-related ageing processes. Products that offer special and universal competencies for multiple work applications or steps. Enables cutting and grinding in just one step – with a disc thickness of 1.9 mm. • Extra-thin cutting and grinding with a single disc • No disc change • Safe through three full-face fabric layers

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Fillet weld flap disc – the combination of a 10 mm flap projection and rigid fabric makes for a long lifetime. • High stock removal performance through ceramic grain • Optimised for fillet weld work • Optimal price-performance ratio

RHODIUS ABRASIVES GMBH

Germany

Special technologies: High-performance ceramic grain tools. For industrial high-throughput grinding applications. Ceramic grain fibre disc – the grain enables superior stock removal performance in a short period of time with a very long lifetime. • Especially suitable for hardened and tempered steels, tinder areas and titanium • Perceivably faster stock removal • Long lifetime

ASSFALG GMBH

Germany

The Neutrix is a small, light-weight and portable electrode grinding machine which is able to centrically grind in longitudinal direction, providing reproducible quality cuts of tungsten electrodes. Electrode diameters from Ø1-4mm can be reground. Only 0.3mm is removed from the grinding electrode during each grinding process. A stand can be mounted for use in the workshop. The point angle can be set gradually from 15-180°. The grinding dust is collected in an integrated filter cassette. The speed can be regulated for an optimal grinding speed. A special collet can be used to grind tungsten electrodes with a length of up to 15mm. The diamond grinding disc can be used three times through an eccentric disc. The grinding process can be observed through a window. The grinding pressure should be used to prevent the electrodes from glowing and thereby avoid early wear to the diamond disc.

Request for a quote

ASSFALG GMBH

Germany

The handy drill grinders are ideal for grinding HSS- and VHM spiral drills. HSS drills are ground with CBN grinding discs and VHM drills with diamond grinding discs. Through the adjustable point angle from 90-140° and the adjustable point thinning equipment, these models can be used universally for different drill types. Easy handling and their efficiency make this machine a real winner in the field of drill grinding. Approx. 0.3mm is removed during each grinding process. The double-bearing grinding equipment guarantees a precise finish. The EDG 213 covers a drill diameter range from 2-13mm and the EDG 1226 from 12-26mm. Advantages: Precise regrinding of HSS and VHM spiral drills Easy operation Compact construction Fast and easy grinding disc change Point angle adjustable from 90-140° Adjustable point angle mechanism Comprehensive delivery accessories

Request for a quote

ASSFALG GMBH

Germany

The KSM 125 and KSM 130 edge grinding machines are designed for deburring and edge cutting of small to big workpieces starting with a thickness of 2 mm. The chamfer is scrubbed and finished in one step with our two-zone grinding disc. The chamfer setting is made by opening / closing the prism. This is used effectively and efficiently through the axial adjustable corundum grinding disc. The KSM 125 has an integrated extraction socket for connection to an extraction system. A water cooler is installed in the KSM 130. The machines are equipped with hardened and polished guide rails. Hardened workpieces and HSS materials can be processed p to 5mmx45° in multiple steps. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machines can be installed on an undercarriage for flexible use in a workshop.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 2 mm thickness. The sturdy cast iron casing, the hardened and sanded guide rails, the speed regulation and the integrated chip box convince in every regard. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clatter-free, clean and constant chamfering. A chamfer width of up to 10 mm is possible in NE metals and a chamfer width of up to 5mm in steel. Hardened workpieces, HSS and hard metal materials can be processed through optional CBN and diamond grinding discs. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop.

Request for a quoteResults for

Grinding discs - Import exportNumber of results

27 ProductsCountries

Company type