- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gear unit

Results for

Gear unit - Import export

ETH MESSTECHNIK GMBH

Germany

Customized Solution Hand-held device with integrated torque transducer. Direct channel selection of filed test programs. Drive of the transmission is achieved to the predetermined moment of friction during the assembly. Subsequent break-in period and subsequent Reibwertprüfung with threshold monitoring, visual evaluation and documentation. Direct channel selection of filed test programs Safety circuit by two-hand operation Constant load independent test speed either vertically or horizontally about Balancer

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Friction measurement on gear with cam recording with service case In order to reduce the frictional torque in a gearbox from the automotive industry, a measuring device that accompanies the development is required. With the DPFR-027, changes in the design can be measured directly on the product. This means that even the smallest improvements can be determined. The field of application of this test device is extremely diverse and can be easily converted to other applications. Thanks to the mobile design, tests can be carried out under different temperatures and climatic conditions. hand-held drive unit compact slim design constant load-independent test speed selectable direction of rotation and speed additional storage to eliminate lateral forces Acquisition of torque and angle of rotation Graphic recording of the test sequence Storage of the test results in Excel

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and ring gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / ring gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible. Saves time and money. Cooperation with companies for special cases. We are looking forward hearing from you.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B70V SanitaryPlus food pump is a powerful positive displacement pump for highly sensitive, viscous media with and without fibres or solids up to the limits of flowability. It pumps liquid foodstuffs, active pharmaceutical ingredients and cosmetic products from a wide variety of containers and delivery packs. The pump fulfils the requirements of hygienic design and is certified in accordance with the "3-A Sanitary Standards". With reduction gear for electric motors up to 230 volts * Also available in special immersion depths * Examples of media: liquid foodstuffs and luxury foods, active pharmaceutical ingredients and cosmetic products * Threadless, manually detachable quick connections in the wetted area * Gentle, low-pulsation product conveyance * Certified and approved in accordance with the current "3-A Sanitary Standards for Centrifugal and Positive Rotary Pumps Number 02-10"

Request for a quote

BVS ELECTRONICS GMBH

Germany

Bosch Rexroth/Indramat Gear The following options are available for gear units, such as travel gears, slewing gears or winch gears, manufactured by Bosch Rexroth/Indramat Purchase a reconditioned replacement part or new part Replace a reconditioned replacement part or new part Purchase product overhaul repair or cleaning & inspection services We will be happy to supply an onsite service incl. support over the phone, upon request. Our extensive replacement parts warehouse with more than 100,000 instantly accessible modules provides our customers with a fast supply of replacement parts ensuring the costs of machine downtimes are kept to a minimum. We are proud to be the only company worldwide from the control and drive industry to bear the status of "Bosch Rexroth Service Point". We are therefore able to provide you with a warranty of up to 24 months* on the services specified above for gears manufactured by Bosch Rexroth/Indramat.

Request for a quote

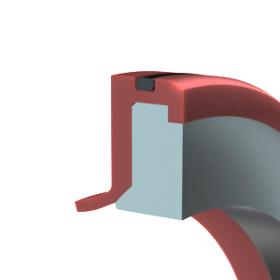

IDG-DICHTUNGSTECHNIK GMBH

Germany

Motor shafts. Gear and frive unit shafts. Fan shafts. Clamping tools. Applications at high speed and lo pressure.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For closed gear units and geared motors, plain and friction bearings even at higher rotating speeds, e.g. on filling and packaging machines For joints, propeller shafts and chains when grease lubrication is specified Advantages and benefits Toxicologically harmless as defined in German LFGB Formula in accordance the FDA guideline 21 CFR 178.3570 NSF H1 registered Long operating times due to good resistance to oxidation and ageing Reduced wear due to highly adhesive, load-bearing lubricating film Excellent corrosion protection Low dynamic viscosity enables use with minimal bearing play and gear unit spaces Good pumpability with central lubricating systems Very high resistance to hot and cold water, watery-alkaline and acidic disinfectants and cleaning agents

Request for a quote

BVS ELECTRONICS GMBH

Germany

Lenze drive technology Regardless of whether you require motors, gear units or specific drive elements, we have an extensive selection of products manufactured by Lenze to meet your exact requirements. This includes frequency converters and servo motors as well as various accessories, such as signal and power cables, function modules, handheld terminals and mounting kits. We not only complete repairs for products manufactured by Lenze but also sell and service these modules.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of heavy loaded toothed gears and worm gears exposed to outdoor conditions and/or low temperatures, as well as tilted or vertical shafts, especially with gear designs which are not oil-tight Lubrication of friction bearings with minimal bearing clearance or high circumferential speeds Advantages and benefits Long-term lubrication due to excellent resistance to oxidation and ageing Wear reduction at maximum loading Prevents leakage with angled or vertical shafts due to good adhesion on metallic surfaces Flowing structure prevents grooving in gear units with continuous coverage of surfaces

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

We also supply renowned customers on an international level with our products for conveying technology (gas and oil extraction) and their gear units. Here is an overview of our production possibilities: Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible We manufacture for different customers: railway, wind power, shipping, conveyor technology, industry and special machine construction. Production is carried out according to customer drawings and standards. Further information in the first interview. We look forward hearing from you.

Request for a quote

BVS ELECTRONICS GMBH

Germany

Bosch Rexroth Group Service Point Since 2015 we have been the only company worldwide in the control and drive industry to bear the "Bosch Rexroth Service Point" status. We supply our maintenance services including the repair, exchange and sale of replacement and new parts for the broad product portfolio of Bosch Rexroth ranging from drives, to motors and gear units, to controllers, plugin cards and all of the accessories. Thanks to the Bosch Rexroth Group Service Point status, you will enjoy many benefits as one of our customers – we would like to present these in further detail on our website. In a direct comparison with other manufacturerindependent repair shops, you benefit from our bundled specialist knowledge of a wide range of different manufacturers, optimum availability, the shortest repair times and great prices thanks to top OEM conditions.

Request for a quote

BVS ELECTRONICS GMBH

Germany

Fanuc accessories The following options are available for accessories, such as gear units, impulse generators or transformers, manufactured by Fanuc Purchase a reconditioned replacement part or new part Replace a reconditioned replacement part or new part Purchase product overhaul repair or cleaning & inspection services We will be happy to supply an onsite service incl. support over the phone, upon request. Our extensive replacement parts warehouse with more than 100,000 instantly accessible modules provides our customers with a fast supply of replacement parts ensuring the costs of machine downtimes are kept to a minimum. All of the repaired assemblies, exchange services and replacement part deliveries of Fanuc accessories come with an 24month warranty*.

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Our crane end carriages, which we have developed in various designs, offer flexibility and high operating reliability. These compact, modular rail-mounted travel units can be connected direct to crane girders and load-bearing structures. Our end carriages consist of a torsionally rigid box section and complete travel units with geared motors and wheels from the Demag modular system, which can be configured for all load capacity ranges. These combinations result in solutions to meet specific application requirements for safe crane and machinery travel motions that are kind to the rails.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

YZ-NP impulse wrench is light weight, well balanced, and has a brushless DC motor. It allows 4 rpm settings (2000/3000/4000/4800) to be set according to application/joint conditions. No planet gear between motor and impulse unit resulting in extremely low vibration and low noise. Available Li-ion battery 18 V / 2.0 Ah provides LED capacity indicator and no memory-effect. LED indication appears on overheat error, motor/driver error, and low battery capacity. Pulse-Check Function: By teaching the tool the impulse cycle as a reference point, the YZ-NP is able to give a warning message for upcoming maintenance needs. Applying reaction-free Yokota impulse wrenches at the assembly line reduces the RSI risk significantly. [...]

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRV - Geared agitator with variable speed gear unit The GRV series can be used in versatile manner. It is equipped with a mechanically variable speed variation drive with drive ratings of up to 11.0 kW. Furthermore it can be supplied with geared drives that have a standard output speed of between 1 and 1,750 rpm. The speed is adjustable with a hand wheel. The agitator shaft of the GRV series geared agitator is directly mounted on the shaft of the mechanical speed variator or with additional speed reduction (all before mentioned solutions possible). The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRV series can be supplied with matching mixing elements and various seals.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Mobile Mobile friction measurement for gear optimization 5 Nm or 30 U/min With the DPFR-036, changes in the design can be measured directly on the product. Even the smallest improvements can be identified. The area of application of this test facility is extremely diverse and can be easily implemented for other applications. The mobile design enables tests to be carried out under different temperatures and climatic conditions. Special features constant test speed independent of load selectable direction of rotation and speed Additional storage to eliminate lateral forces Acquisition of torque and angle of rotation Graphical recording of the test procedure Simultaneous viewing of up to 20 variable test sequences from the database in color Option OK and NOK signal lights

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The LRD series top-entry sealed agitator can be used for mixing in closed containers with a mechanical seal. It is designed with a coupling housing. The agitator shaft is borne in the bearing housing and the mechanical seal (single- or double-acting). The seal can be exchanged without dismantling the mixer from the tank (also in case of a side entry). Drives with shaft journals for LRD series: Three-phase motor Helical geared drive unit Parallel shaft geared drive unit Variable speed geared drive unit Helical bevel geared drive unit According to the tank size, the LRD series agitator is available in four different frame sizes. Shaft diameters of 30 mm to 90 mm and shaft lengths of up to 10,500 mm are feasible. Explosion protection to ATEX 2014/34/EU for explosive zones 0 to 2 for gases and for explosive zones 20-22 for dusts (device group II, categories 1-3). Pharmaceutical version with FDA and GMP feasible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEPPERT RÜHRTECHNIK GMBH

Germany

KRK coaxial agitator features two different impeller systems for parallel mixing. The KRK has two interdependent agitator shafts with a different number of revolutions that move in opposite directions. The faster agitator shaft is supported in the slower hallow shaft of the geared mixing unit. The KRK series is primary suitable for the dispersing of highly viscous media. The heat transfer is promoted. Explosion-proof series certified to ATEX Directive 2014/34/EU zone 0 and zone 1.

Request for a quote

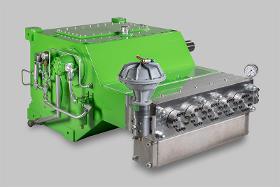

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

KRK - Coaxial agitator KRK coaxial agitator features two different impeller systems for parallel mixing. The KRK has two interdependent agitator shafts with a different number of revolutions that move in opposite directions. The faster agitator shaft is supported in the slower hallow shaft of the geared mixing unit. The KRK series is primary suitable for the dispersing of highly viscous media. The heat transfer is promoted. Explosion-proof series certified to ATEX Directive 2014/34/EU zone 0 and zone 1.

Request for a quote

RUHRGETRIEBE KG

Germany

Energy and sustainability are terms that are shaping this decade and will take on an ever increasing role in the production systems of the future. With ENEX gear units and gearmotors, we provide drive components that can meet future requirements in terms of efficiency and performance. The newly engineered ENEX-LINE represents sustainability, long service life, modularity, high efficiencies and therefore combines the most important features into a compact gear unit which, despite the space-saving design, has an enormous technical performance. Key facts: — Nominal torque: 25Nm — Available ratios: i = 15, i = 24, i = 49 — Efficiency up to 77% — Low noise emissions — Input hollow shaft IEC standard Our sales team will be happy to advise you on questions or configurations - get in contact!

Request for a quote

RUHRGETRIEBE KG

Germany

Single-stage worm gear unit for restricted installation spaces. Highly flexible in use. Available with or without electric motor. Key facts: — Nominal torques: up to 4.7 Nm — Available ratios: i = 3, i = 7, i = 10.5, i = 15, i = 21, i = 30, i = 40, i = 68, i = 110 — Efficiencies up to 79 — Low noise emissions — Food-grade gear grease, i.e. all ingredients meet USDA H1 or FDA regulations for use in the food industry Our sales team will be happy to advise you on questions or configurations - get in contact!

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The PSU 450 GS is a circular saw specially designed for sawing curved tubes such as mufflers, hydroforming or exhaust pipes. Standardised mounts and their flat material table enable individual workpiece fixtures to be accepted. The saw entry and exit point can be freely adjusted accordingly. The standard two-hand operation allows comfortable and safe working without disturbing mechanical guards. The heart of the PSU tube cutting saw is the worm gear unit with EISELE shock-absorbing feature, produced in-house. It is heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface and the blade life. + Mounting for part-specific fixtures + Adjustable saw entry and exit point + Robust and durable + Micro spray system

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Semi-automatic machines for single cuts and small seriesWith automatic saw feed and quick-clamping device for the material, the semi-automatic models offer higher cutting output levels and more operating convenience than the manual saw variants. By ensuring fatigue-free working for the operator, they are also suitable for sawing small production runs: Quick-acting pneumatic / hydraulic clamping device Clamping pressure reduction available as option Variable hydro-pneumatically / hydraulically controlled setting of the saw blade feed Easy miter cutting positioning with fixed stop Easy stroke adjustment of the saw unit via 2 clamping levers Well dimensioned worm gear unit with EISELE shock-absorbing feature Quick and easy blade change

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Universal, precise and fast - these are the performance features of the PSU 450 H semi-automatic mitre saw for cutting metals. Designed for cutting profiles, pipes and solid material in metal and comparable materials, this machine is specifically designed to address the needs of locksmiths and metalworking shops. The mitre setting is equipped with convenient fixed stops at 90°, 45° and 30°. The 450 mm diameter saw blade used offers a wide cutting range - also for mitre cuts. The heart of the PSU mitre saw unit is the worm gear unit with EISELE shock-absorbing feature, produced in-house. It is heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface and the blade life.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Simple operation, robust design and precise cuts make the metal-cutting cold saws of the VMS series a reliable partner in the workshop and factory. They are real all-rounders when it comes to cutting solid materials, tubes and profiles. In addition to the automatic saw feed, the VMS 350 PV also offers pneumatic clamping of the material. The heart of the VMS circular saw unit is the worm gear unit with EISELE shock-absorbing feature, produced in-house. It is heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface, the blade life and the service life of the saw. A quick change of the saw blade is easily possible thanks to the large safety hood. The hydro-pneumatic saw feed can be adjusted infinitely.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD4HD/-30° can be used for refacing the external conical landing face on valve cages. Capacity Max. refacing diameter 250mm Angle of transverse feed -30° Features Drive unit and gear head of the VD4HD/-30° are identical with the drive unit and gear head of the VD4E Valve Seat Refacing Machine. If a VD4HD is already on hand, only the D4/-30° adapter head is required for refacing the external conical landing face on valve cages. The D4/-30° adapter head is bolted to the gear head in place of the seat refacing adapter head. The pilot used for valve seat refacing can be also used for centering the VD4HD/-30°.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD4HD-RC is designed for refacing • the landing surface for the cylinder liner on the engine block, • the landing surface for the cylinder head on the cylinder liner and • the landing surface for the cylinder liner on the cylinder head. Features Drive unit and gear head of the VD4HD-RC are identical with the drive unit and gear head of the VD4HD Valve Seat Refacing Machine. If you have already a VD4E machine and you want to use it with our new face turning heads, we can convert it into the new high performance VD4HD System. The three available face turning heads should be used according to our recommendation with the VD4HD drive unit and the related power supply type 4HD. We would be glad to advise you about our new VD4HD system and send you an offer for this. The D4/0° adapter head is bolted to the gear head in place of the valve seat refacing head. The VD4HD-RC is centered by a pilot assembly which is designed to fit to the engine component to be serviced.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Eickhoff offers application-specific solutions for winch systems in the field of lifting and conveyor technology. Even torques of over 2500 kNm are no problem. Our planetary gearboxes are characterised by a compact design and high power density, which is particularly advantageous in space-critical fields of application such as the maritime sector. The direct integration of our gearboxes into the rope drums can be realised individually. Due to the high efficiency of the planetary and spur gear units, they operate with extremely low losses. Based on our modular system, solutions can be derived individually adapted to the respective application. Advantages at a glance: — Compact design — High efficiency — Reliable and low maintenance — Customized solution

Request for a quoteResults for

Gear unit - Import exportNumber of results

31 ProductsCountries

Category

- Automation - systems and equipment (4)

- Sawing machine tools (4)

- Gears (3)

- Measurement and control instruments (3)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Pumps (2)

- Silicones (2)

- Cranes and gantries (1)

- Gas and oil - exploitation (1)

- Mechanical transmission systems and components (1)

- Multipliers, speed (1)

- Oil - drilling and extraction (1)

- Paint mixers and grinding machines (1)

- Sealing rings (1)

- Tightening wrenches (1)

- Transmission elements (1)

- Turning - steels and metals (1)