- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gear lubrication

Results for

Gear lubrication - Import export

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Molub-Alloy 936 SF Heavy. Open Gear Lubricant (Solvent-Free) Description Castrol Molub-Alloy OG 936 SF Heavy (previous product name Castrol Molub-Alloy 936 SF Heavy) is an open gear lubricant specifically developed for use in heavy-duty mining and industrial equipment . Castrol Molub-Alloy OG 936 SF Heavy is designed to provide maximum protection to gearboxes and rails of large draglines and buckets, while keeping potential environmental contamination to a minimum . The contained mixture of Molub-Alloy solid lubricants optimizes wear protection and load capacity. The selected solid lubricants work synergistically with chemical anti-wear (AW) and high-pressure additives (EP), reduce temperatures in the contact zone and offer good anti-seize protection under high loads and shock loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste MF. Silver-grey high-temperature paste with solid lubricants Description Castrol Molub-Alloy Paste MF (previous product name Castrol Optimol Paste MF) is particularly suitable for assembling screw connections in the high temperature range up to +1100 °C . Even under extreme pressures, it protects the surfaces from scoring, corrosion and seizing. In high-temperature areas, in wet conditions and in aggressive environmental influences, Castrol Molub-Alloy Paste MF seals the components and ensures good separation. Application Castrol Molub-Alloy Paste MF can be used for components at risk of corrosion, exposed to high temperatures and the environment , such as hot-screw connections, spark plug and lambda sensor threads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Transmax Dual with Smooth Drive TechnologyTM is a fully synthetic, smooth-running transmission oil that was specially developed for dual clutch transmissions from various car manufacturers such as Ford, Volvo, Chrysler, Dodge and Mitsubishi . Also recommended for use in the DQ 250 (DSG) dual clutch transmission according to VW part number G 052 182 for VW, Audi, Seat and Skoda. Transmax Dual offers original quality as it is provided for in the factory filling by the manufacturers listed. Specifications Audi / VW TL 52529 (G 052 529) Castrol Recommendations Recommended for use in: Ford WSS-M2C-936-A (Dual Clutch), Volvo, Chrysler (Europe), Mitsubishi, Peugeot using Getrag DCT, VW G 052 182; PSA Transmission Oil 9734 52; Dia Queen SSTF-1 VW, Seat, Skoda 6-speed Dual Clutch Transmission (DSG)

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For highest contact pressure and high circumferential speed, e.g. for rotary kilns, ball mills, rotary barrel mixers, ball mills, rope winches or friction presses also for guiding elements, slide bars, heavy transport chains and closed wire ropes Lubrication of rotating assemblies of convertors, cranes, crushers and dredges with spray or central lubricating systems Lubrication of heavily loaded gear couplings Advantages and benefits Most suitable for reliable supply of open gears, even at high circumferential speed Very efficient through EP additives in association with a specific combination of solid lubricants and adhesive additives Reliable protection of tooth flanks, even at high temperatures and with extended relubrication time Good pressure resistance of the lubricating film, excellent wear protection The film is not embrittling and aging. Without bitumen, solvent, does not contain heavy metals

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Molub-Alloy 936 SF Heavy. Open Gear Lubricant (Solvent-Free) Description Castrol Molub-Alloy OG 936 SF Heavy (previous product name Castrol Molub-Alloy 936 SF Heavy) is an open gear lubricant specifically developed for use in heavy-duty mining and industrial equipment . Castrol Molub-Alloy OG 936 SF Heavy is designed to provide maximum protection to gearboxes and rails of large draglines and buckets, while keeping potential environmental contamination to a minimum . The contained mixture of Molub-Alloy solid lubricants optimizes wear protection and load capacity. The selected solid lubricants work synergistically with chemical anti-wear (AW) and high-pressure additives (EP), reduce temperatures in the contact zone and offer good anti-seize protection under high loads and shock loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Castrol Syntrax Longlife 75W-90 is a fully synthetic axle gear lubricant for cars, heavy and light commercial vehicles and tractors. The performance reserves of Castrol Syntrax Longlife 75W-90 exceed the API class GL-5 and allow a significant extension of the existing oil change intervals (according to manufacturer regulations). Castrol Syntrax Longlife 75W-90 can be used in all axle drives and differentials without a multi-plate lock if a GL-5 lubricant with SAE 75W-90 is required. Advantages -Extremely high pressure absorption capacity -Excellent high-temperature stability -Significantly reduced gear oil temperature -Absolute shear stability -Excellent lubrication security at very low temperatures -Neutral sealing behavior -Excellent foam resistance -Extended oil change intervals possible (observe manufacturer's instructions) Specifications API GL-5 MAN 342 Type S1 Scania STO 1:0 ZF TE-ML 05A,12B,17B,19C,21A BMW (Non LS Rear Axles)

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For lubricating machine elements under high loads (also under water influence) Lubrication of chains, joints and guides Lubrication of rolling and friction bearings Lubrication of toothed gearings, fittings, hinges and locks Advantages and benefits NSF H1 registered MOSH/MOAH-free The optimal additives allow good resistance to oxidation and ageing for long operating and durability Resistant to cold and hot water, steam and alkaline and acidic disinfectants and cleaning agents

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For lubricating machine elements under high loads (also under water influence) Lubrication of chains, joints and guides Lubrication of rolling and friction bearings Lubrication of toothed gearings, fittings, hinges and locks Advantages and benefits NSF H1 registered MOSH/MOAH-free The optimal additives allow good resistance to oxidation and ageing for long operating and durability Resistant to cold and hot water, steam and alkaline and acidic disinfectants and cleaning agents Also available as spray version OKS 3751

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Molub-Alloy 936 SF Heavy. Open Gear Lubricant (Solvent-Free) Description Castrol Molub-Alloy OG 936 SF Heavy (previous product name Castrol Molub-Alloy 936 SF Heavy) is an open gear lubricant specifically developed for use in heavy-duty mining and industrial equipment . Castrol Molub-Alloy OG 936 SF Heavy is designed to provide maximum protection to gearboxes and rails of large draglines and buckets, while keeping potential environmental contamination to a minimum . The contained mixture of Molub-Alloy solid lubricants optimizes wear protection and load capacity. The selected solid lubricants work synergistically with chemical anti-wear (AW) and high-pressure additives (EP), reduce temperatures in the contact zone and offer good anti-seize protection under high loads and shock loads.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of closed toothed gearing Liquid lubrication of chains, joints, guides, rolling and friction bearings Suitable for immersion-bath, immersion-bath circulation and injection lubrication Advantages and benefits NSF H1 registered Good ageing and oxidation stability through optimal additives Cold and hot water resistant Resistant to water steam, disinfectants and cleaning agents Wide operating temperature range Shear-stable and low-foaming Good wear protection Good corrosion protection Long economic operating times MOSH-/MOAH-free

Request for a quote

AAAGILER GMBH

Germany

Collapsible emergency sumps / pans / spill containment are the ideal solution for the immediate collection of non-critical and critical liquids. These innovative drip pans reliably prevent the contamination of groundwater and the environment if fuels, lubricants, hydraulic or gear oils and acids leak unexpectedly.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of closed toothed gearing Liquid lubrication of chains, joints, guides, rolling and friction bearings Suitable for immersion-bath, immersion-bath circulation and injection lubrication Advantages and benefits NSF H1 registered Good ageing and oxidation stability through optimal additives Cold and hot water resistant Resistant to water steam, disinfectants and cleaning agents Wide operating temperature range Shear-stable and low-foaming Good wear protection Good corrosion protection Long economic operating times MOSH-/MOAH-free

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of closed toothed gearing Liquid lubrication of chains, joints, guides, fittings Suitable for immersion-bath, immersion-bath circulation and injection lubrication Advantages and benefits NSF H1 registered Good oxidation and ageing stability through optimal additives Cold and hot water resistant Resistant to water steam, disinfectants and cleaning agents Wide operating temperature range Shear-stable and low-foaming Good wear protection Good corrosion protection Long economic operating times MOSH-/MOAH-free

Request for a quote

J.D. NEUHAUS GMBH & CO. KG

Germany

JDN Air Hoists PROFI 3 TI up to PROFI 100 TI also available as hydraulic hoists. PROFI 3 TI JDN Air Hoists PROFI Carrying capacities: 250 kg up to 100 t Air pressure: 4 bar or 6 bar Standard Features suitable for application in hazardous areas (Explosion protection) sensitive infinitely variable speed control for the precise positioning of loads easy operation suitable for lube-free operation frequent switching and extended duty cycles low maintenance low headroom, lightweight sound absorption insensitive to dust, humidity and temperatures ranging from -20°C up to +70°C from 1 t upwards with overload protection (EC-version) Technical Details fail-safe starting conditions, low maintenance vane motor chain sprocket in the mid section runs in dust proof maintenance free ball bearings planetary gear in long life grease lubrication, all teeth made of tempered or hardened high grade steel chain and hook of high quality tempered steels with a breaking strength of five times the...

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/af/c8/dynaGear-Ritzel_67543e7d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B= 53 Nm to 2160 Nm Feed forces up to approximately 35 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 10 m/s Gear ratios from 3:1 to 100:1 Spur gear modules from m2 to m6

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/84/ee/dynaGear-Eco_0992140d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems With planetary gear output flange 3 sizes from T2B= 53 Nm to 210 Nm Feed forces up to 8 kN 2 precision classes Input speeds up to n1max = 5000 min-1 Feed speeds up to 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from m2 bis m4

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/4c/de/de-dg-system_7cee2ba1.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 4 sizes from T2B= 53 Nm to390 Nm Feed forces up to 11 kN 2 precision classes Input speeds up to n1max = 6000 min-1 Feed speeds up 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from to m2 bis m4

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

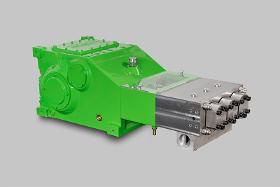

KAMAT GMBH & CO. KG

Germany

With 110 kW, the K11000-3G high-pressure pump is a powerful plunger pump that is mostly used in intermittent operation. The reason for this is that this KAMAT high pressure pump has splash lubrication and not oil pressure lubrication. This makes the pump more suitable for intermittent operation, but it is extremely robust and can therefore be used in continuous operation even at 110 kW. Classic applications for this pump are industrial cleaning, blasting and process engineering. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Splash lubricated gearbox - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils etc. on request, oils etc. on request

Request for a quote

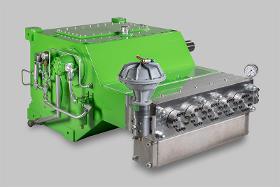

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description spindle extension SV-560/X P=30 kW, n=5,000 RPM, M=850 Nm Construction principle: - intention spindle stationary - Eccentricity: 160 mm - SK 50 with automatic tool clamping - with internal and external coolant supply - Lubrication: minimum oil/air lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 560 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - right angularity : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-2/90 P=15 kW, n=1,500 RPM, M=500 Nm Construction principle: - Positioning and clamping: manual - SK 50 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1.68 : 1 - Manufactured length (up to spindle centre): 750 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-1/90 P=7 kW, n=3,500 RPM, M=150 Nm Construction principle: - Positioning and clamping: manual - SK 40 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 495 mm / 645 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-4/90 P=30 kW, n=3,000 RPM, M=1,000 Nm Construction principle: - Positioning and clamping: manual - SK 50 without automatic tool clamping - with internal and external coolant supply - Lubrication: grease lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 515 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quoteResults for

Gear lubrication - Import exportNumber of results

30 ProductsCountries

Company type