- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas heating system

Results for

Gas heating system - Import export

MERECS ENGINEERING GMBH

Germany

Merecs develops individual test systems for heat pumps, gas, fluid and water systems. Our engineers & fitters for electronics, installation technology and mechanics build the systems completely from one source at our location in Steinfurt. The systems are then delivered and commissioned at home and abroad. Our range of products includes - Development test benches - Life time test benches - End-of-line test benches (production) - Retrofit of existing systems (software / hardware) - Climate & temperature test systems - Leakage test benches - Software development LabVIEW, TestStand, Python, C/C++ (Embedded), Microsoft PowerBI, SQL - Electronics development - Mechanical 3D CAD design

Request for a quote

ELMESS-THERMOSYSTEMTECHNIK GMBH & CO. KG

Germany

Electrical air heaters for air or process gas heating in pressureless systems: · Ventilation systems, Ex HVAC plants · Supply air heaters for machines · Heating of process gases · Heating of containers or heating chambers ATEX, IECEx, TR-CU and other international certificates

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

Flowmeters especially for gases The VA 45 variable area flowmeters were designed to measure gases. They can be used, for example, in industrial ovens, forges and furnaces, and protective gas and heating systems. The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly.

Request for a quote

JINTIAN COPPER

Germany

Main products: Brass valves, cast iron valves, gas valves, plumbing and sanitary ware, water meters and various types of pipe fittings and accessory products Applications: Water supply and drainage systems, gas systems, urban heating, HVAC and piping connections Honorary titles: High-tech Enterprise, Famous Chinese Valve Brand, Zhejiang Manufacturing Certification

Request for a quote

ERC ADDITIV GMBH

Germany

ERC Guard Bio Thermic is the first TÜV tested high-performance additive for heating oils with up to 20% bio-components. With organic combustion enhancers, can be used in all DIN heating oils. The Effect ERC Guard Bio Thermic is the first high-performance additive certified by TÜV NORD for low-sulphur heating oil with a bio share of up to 20%, combination with high sulphur heating oil (1.000 ppm sulphur) is also problem-free. The comparative endurance test of TÜV NORD demonstrated the spectacular effect of ERC Guard Bio Thermic on the low-sulphur heating oil used in the test. There were no ageing products on the tank bottom and no corrosion. The Result ERC Guard Bio Thermic assures stable heating oil flow through the nozzle. Even after a burner operating time of 1,510 hours, there was no increase of exhaust gas losses. The heating system with heating oil without additives operating in parallel was then measured as an emissions 'polluter'.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

THIELMANN ENERGIETECHNIK GMBH

Germany

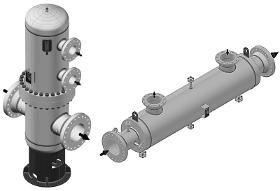

TUBE BUNDLE HEAT EXCHANGER, TYPE VEV/VEV-L/VEV-ex Gas / Water; horizontal / vertical CHARACTERISTICS Optimal load case design Flow stream optimized design Vibration-optimized design OPTIONS Customer-specific design for various design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) Design according to TEMA Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Customer-specific nozzle arrangement GENERAL Heat exchangers (heat exchangers) heat gas for a subsequent system requirement or to counteract the Joule-Thomson effect. For example, For example by pressure reduction in a gas-pressure control. Heat exchangers can also be determined in the reverse mode of operation as coolers. The design is carried out as a steel welded construction in vertical or horizontal design.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

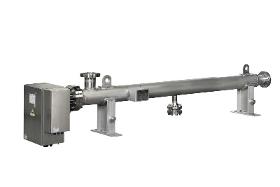

CSN® explosionproof flow heaters are used for heating up flowing gases and liquids in hazardous areas. The devices consist of explosionproof flanged immersion heaters, which are installed in corresponding pipe or pressure vessel. Our products realize individual solutions for complicated technical process. Different heating systems for heating up liquids, nitrogen or other gases activate exact determinded processes in chemical factories. In close discussion with our customers problems will be defined and changed in technical optimale solutions. Our QualityManagementSystem ensures the high quality level of our customers. Further information about our CSN® Exflow heater

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Like the slightly less powerful MA series, it is guaranteed absolutely exhaust-free hot air. In addition, the units can be operated not only with oil, but are also approved for gas operation. The operating mode can be flexibly adapted to the conditions on site. Thus, the devices can be used in all areas. Hot air hose systems can also be connected without any problems thanks to the high-performance radial fans. Consequently, effective heating from outside is also possible without any problems. The recirculation module ensures efficient and economical operation. The oil burner blowers are made of high-quality materials by renowned manufacturers. They work so efficiently that 93% of the energy can be converted into heat.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

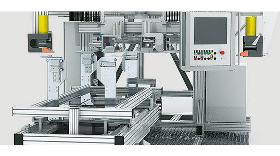

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

nduction Heating and Joining in one turnkey system. This turnkey system is used to heat electric motor housings with various dimensions for a wide range of joining processes. Example Heating System 1: the die-cast aluminium housing for an asynchronous motor (diameter 450 mm) is heated to approx. 290°C in approx. 5 minutes to fit the wound stator package. The parts are loaded and unloaded from the feeding belt parallel to the working time. The heating process takes place in two independent work stations. The generator has a switched output which means that only one generator is required for the two heating stations. The system is controlled using a SIEMENS PLC controller. Example Heating System 2: the aluminium housing (diameter 140 mm) of a synchronous motor is heated to approx. 280°C in approx. 3 minutes to fit the stator. The component is loaded into and unloaded from the heating station semiautomatically. The system is controlled using a PLC.

Request for a quoteResults for

Gas heating system - Import exportNumber of results

11 ProductsCountries

Company type