- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas control

Results for

Gas control - Import export

ORBITEC GMBH

Germany

The Gas Controller Box enables to control up to three gases during welding and regulate them through the EVO WP controllers. The welding, the purging, and an additional gas (e.g., for a trailing nozzle, for flooding a gas cover or a housing) can be monitored, regulated, completely documented, and stored in the EVO controllers. All welding and purging gases that are used for TIG welding are memorized in the controller menu.

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

NOVOTECHNIK MESSWERTAUFNEHMER OHG

Germany

Application: E-gas, idle speed control The information detected from the pedal sensor are transmitted to the electric motor-driven throttle valve positionier via control and correction electronics. The current throttle valve position is measured by an integrated or adapted angle sensor. The idle controller regulates independent of the load the idling speed or the engine through the throttle position. This leads to an optimised fuel consumption. Automotive Applications.pdf For more information please contact: automotive@novotechnik.de, +49 711 4489-222

Request for a quote

APROVIS

Germany

What you can expect from APROVIS steam generators: - Efficient steam generation in combined heat and power plants - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Performance areas: 1 to 25 baro, 100 to 25,000 kg/h - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives - Single, double or triple version for operation with one, two or three engines with completely separate exhaust gas sections - The APROVIS Controlling System (ACS) is individually adapted to each project and is delivered in the required language - Access to the ACS using a modem enables easy fine-tuning of the system or remote maintenance for swift support if and when discrepancies occur during operation

Request for a quote

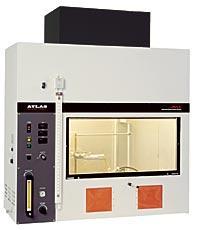

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HMV is the preferred flame chamber for conducting burn rate and burn resistance tests on automotive interior materials. Its durable stainless steel construction, large glass viewing window, door- mounted burner and lift-off top cover for easy specimen access greatly enhance user convenience. The loading of specimens is simplified with a unique snap-together specimen holder. The optional Automatic Gas Control (AGC) features a digital timer and push-button gas controls that provide automatic or manual flame impingement modes. The Atlas HMV was designed with the user in mind. Worldwide use for qualification of automotive interior materials Stainless steel chamber with removable top Door-mounted burner with flame height adjustment and pilot ignition Stainless steel U-shaped specimen holder with support stand Specimen supporting wire Stopwatch and measurement scale Separate enclosure for gas controls Specimen holder assembly Stainless steel cabinet Specimen support frame Dimensions: 38cm (15'') W x 20cm (8'') D x 38cm (15'') H Weight: 11 kg (28 lbs.) Automatic Gas Control (AGC) System for automated flame impingement and piloted ignition

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Typical areas of use for hydraulic gas spring are controlled opening and closing of hatches and hoods. The gas springs can also be adapted to control complete equipment such as ventilation apertures, chairs, beds, windows, tools and machinery.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Control gas streams and oxygen in the aquarium For fish tanks and aquariums, manufacturers trust POREX ® aquarium bubbler components. Designed to efficiently introduce bubbles into water to optimize oxygen transfer into the aquarium tank. Available in tubes and custom-molded shapes, our aquarium bubbler solutions: Consistently introduce gas streams–Bubblers ensure efficient and consistent introduction and diffusion of gas streams into the water. Optimize oxygen transfer – Even pore size distribution creates more uniform, small bubbles. request sample ask an engineer

Request for a quote

INFICON GMBH

Germany

UNLOCK YOUR PROCESS Unparalleled Performance for Increased Yields and Maximum Uptime The ever increasing price of silicon wafers and demand for finished products means that scrapped wafers cost more than ever before. Thus, understanding your process and monitoring for defects has become a much higher priority in semiconductor fabrication centers. The Transpector MPH Gas Analysis System is designed to unlock your process with industry leading performance for all of your gas analysis applications to help maximize chip yields and minimize tool downtime. Combined with a low overall cost of ownership and high mean-time-between-failures, Transpector MPH helps your bottom line more than any other residual gas analyzer (RGA) on the market. INFICON has leveraged its expertise in gas analysis process control equipment to create an RGA with industry-leading data collection speed, minimum detectable partial pressure and signal-to-noise ratio. All this, without sacrificing any of the...

Request for a quote

INFICON GMBH

Germany

The Sensistor ILS500 is a fully integrated leak testing system that controls tooling, tracer gas handling, test sequencing and leak testing — all behind an easy to use color touch screen display. The compact instrument helps you get a fast start for your leak testing by guiding you through the setting of parameters. It controls the gas handling so that you have gas at the right time, the right place and at the right pressure. It makes a gross leak test before spending any tracer gas unnecessarily and also assures that the used tracer gas is evacuated after the test. The tooling in your fixture is controlled by the ILS500, and the complete system is able to execute orders from a PLC or other type of computer. With the dual probe possibility, you are even able to first leak test an object with the automatic probe and immediately thereafter do leak locating with the hand probe. The Sensistor ILS500 is the perfect system for solutions ranging from manual sniffing to being a key...

Request for a quote

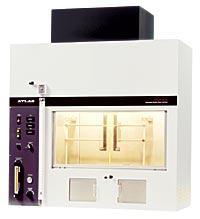

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HVUL2 Horizontal Vertical Flame Chamber is designed for the flammability testing of plastic materials used in consumer electric devices and appliances. The chamber is constructed of stainless steel with a black interior and large sliding window for easy viewing. The HVUL2 includes a fully adjustable specimen support and a precision metered gas burner. Three digital timers with remote control are mounted on the inside back wall of the chamber, allowing for precise and simplified operation. Burner angle adjustable to 0º, 20º, 45º Flexible iris hand access ports Remote burner positioning Sliding tempered glass viewing window Removable burner carriage assembly Flexible laboratory fixturing Interior light Digital timers located in line of sight with specimen Digital timers with resolution of 0.1 sec Remote control with push button reset for in-chamber event timing. Electrical gas shut-off solenoid Gas control system Flame confirmation kit (ASTM D5207) Black interior finish Performs all UL 94 tests (Except Section 10.0 Radiant Panel Test) Bench top chamber (Volume greater than 0.75 m 3) Tirril Burner Multi-directional specimen and burner positioning apparatus Quick release mount for burner during manual operation Large sliding, tempered-glass window for test viewing Exhaust blower (1/3 hp) with variable speed control (580 cfm in free air) Sliding damper for draft free chamber Manometer/pressure gauge, 300 mm Four flame height and sample gauges Interior Dimensions: 122 cm (48'') W x 112 cm (44'') H x 60 cm (23.5'') D Exterior Dimensions: 122 cm (48'') W x 140 cm (55'') H x 61 cm (24'') D Bench Weight: 163 kg (360 lbs) Simple burner angle adjustment (0°, 20°, 45°) Specimen holders for all five Bunsen burner tests Digital timers for specimen test duration, 0.1 sec. resolution Remote control with push button reset for in-chamber event timing Quick release mount for burner during manual operation Hand access openings with irises for closed window access

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HVFAA Horizontal Vertical Flame Chamber provides the most accurate means for determining the flammability of aircraft cabin and cargo compartment materials, liners and waste stowage compartment materials, and electric wire. The large volume chamber prevents oxygen depletion during tests. Three digital timers with remote control make specimen event timing precise and convenient. To ensure accurate and repeatable tests, an optional burner flame temperature verification kit is available. The HVFAA is the optimal instrument for conducting repeatable FAA flammability tests. Designed to be used for testing in accordance with FAA's Aircraft Material Fire Test Handbook DOT/ FAA/AR-00/12, Chapters 1.0 - 4.0 (FAR 25.853, 25.855, 25.1359) Draft-free large volume (>0.5m 3) flame chamber Vertical, Horizontal, 45 Degree and 60 Degree Wire Test Packages Sliding hand ports for chamber access Regulated gas control system Calibrated gas flow meter with precision needle valve adjustment ASTM D5025 Bunsen burner with remote positioning Stopwatch plus three handset operated digital timers Tempered glass sliding window Interior inspection light Flame height gauge High temperature exhaust blower with variable speed control ASTM D5207 flame confirmation kit

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Explosionproof/flameproof gas preheater EEx d -ATEX und IECEx zertifiziert In general a cooling down takes place at expansion of gases whilst a heating takes place at compression. Typical gases are carbon monoxide, natural gas and air. The temperature change, which occurs at expansion of gas or gas mixture from a high to low pressure i.e. after a gas pressure control is called Joule-Thomson effect. In order to prevent the effects of Joule-Thomson as icing or condensate separation, the gas will be heated up before expansion. The gas pre heaters are suitable for all kind of gaseous media (i.e. air, natural gas, technical gases, fuel gas) and low flow process applications, suitable for pressures up to 300 bar. The “Cast electric heaters” type flameproof electrical gas pre heaters are certified for use in zone 1 or 2 hazardous area, custom built to meet client specification. The gas pre heater consists of a process tube coil and an electrical heating bundle, casted in aluminium. The process gas flows through the tube coil and is heated by the aluminium block that provides the heat transfer. This indirect electric heating gives an accurate control of the process and eliminates pressure vessel design and associated costs.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

ATEX certified flameproof thermostats ATEX II 2 G/D EEx d IIC T6 The Exheat „AFT“ flameproof thermostat are ATEX certified, suitable for installation in zone 1 or 2 and 21 or 22 hazardous areas. It has external adjustment enabling quick & accurate variable control for liquid, gas and air applications.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Two independent firing units and flue gas paths create a double control range for individual heat consumption. — Very high efficiency across all power ranges — Particularly suitable for highly fluctuating heat and process heat demand — Reliable solutions for heating plants and the manufacturing industry with temperature levels up to 225 °C — Heat supply for the future: Low-NOx or CO2-neutral operation possible — Complete system with intelligent control technology and protected remote connection — Proven and durable boiler technology Made in Germany

Request for a quote

ORBITEC GMBH

Germany

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters. The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions... Package includes: — Orbital welding system — Display transport protection — Calibration certificate — USB stick Optional: — Water Cooling Unit COOL 50 or EVO COOL — EVO Remote Control — Gas Controller Box

Request for a quote

ORBITEC GMBH

Germany

The EVO Industry 4.0 series is new to the market. Several systems, initially compact as the 200 A Autorange and now also modular in connection with the Tetrix inverters. The systems are small, lightweight and handy and offer a high-resolution colour display, multilingual intuitive user guidance due to a colour touch interface, or alternatively operation using a membrane keyboard, a stable operating system (without data loss during power outages and quickly ready for use again), full access through tablet with QR-code scanner, data transfer via USB, LAN and WLAN, fault analysis program, manufacturer support via remote maintenance, a mountable cooling unit as an option, and many other functions... Connection to Tetrix 200 or Tetrix 351. Compact and light with the external dimensions (L x W x H) 405 x 325 x 170 mm and weighing only 9.7 kg. Optional: — Water Cooling Unit COOL 50 or EVO COOL — EVO Remote Control — Gas Controller Box

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The vacuum packgaing machine AZ450ES from AIRZERO is working with a suction nozzle compared to vacuum chamber machines. The main advantages are Since only the bag and not the entire chamber is emptied, the process is faster. Lower gas consumption when gassing (only the bag is gassed and not the entire chamber). The gas is blown into the bag in a targeted and controlled manner. No limitation of the bag length by the chamber. Bar goods can therefore also be processed. Compact standalone device. double sealing (up/down) ejektorvakuum pump (air pressure required) gas flushing vacuum creation timer controlled, sensor controlled digital vakuum display 4 programms can be saved housing of stainless steel suitable for cleanroom

Request for a quote

EP EHRLER PRÜFTECHNIK ENGINEERING GMBH

Germany

Over the last few years, we at EP-E have designed and introduced a range of primary standards designed for use in calibration laboratories. As a technology partner of the Physikalisch-Technische Bundesanstalt (PTB) in Braunschweig, Germany, our solutions are based on the highest standards. The EP gas bell plungers generate a volume flow which is traceable to the SI units length and time. The pistons are driven by a stepper motor via a spindle. In the initial state one piston is fully retracted and the other fully extended. The volume flow can be set with high precision via the piston cross section and the travel speed. At the end of the calibration process, both pistons are in the opposite position to the initial position.

Request for a quote

COMPUR MONITORS GMBH & CO. KG

Germany

Fixed gas detection system for oxygen, toxic and combustible gases This DIN – rail mounted modern control module saves space, money and installation time. One safe controller for all gases: Any combination of a sensor head plus control module is a complete gas detection system. This makes the Statox 501 so safe and reliable. The Statox 501 also gives you the opportunity to alter or expand existing systems with minimum cost and labor. Programs for all gases and measuring ranges are permanently stored in the memory of the controller. The user-friendly software program allows authorized personnel to select different configurations by a simple push of a button. Easy to install and easy to use The controll modules as well as the power supply and the common alarm module clip on to a DIN rail. The remote sensor heads and any alarm or recording devices connect to terminals on the front of the module. Each Statox 501 control module has three relays for alarm 1 and 2 and system failure (115 / 230 V AC / 2 A). An analog output for recorder or process control systems is also included. Measured values are displayed on a 4 digit LED-display. It is easy to program or calibrate the Statox 501! Just follow the menu! If intrinsically safe transmitters are to be installed in division 1 areas, they can be connected via intrinsically safe repeaters. 24 V power supply as well as the signals for the common alarm module are transmitted via bus from one module to the next. All terminals are easily accessible from the front. Field proven sensors for reliable gas detection Compur manufactures electrochemical sensors for the detection of oxygen deficiency and toxic gases. These sensors generate an electrical current proportional to the actual gas concentration. The remote sensor heads are designed as intrinsically safe certified 4 - 20 mA transmitters and have an integrated concentration display. Combustible gases can be detected with a variety of catalytic beads (pellistors) or infrared technology. The sensor heads are certified "Ex d" or "Ex de" and can be connected directly to the control module, even if they are to be used in classified areas. The control module can supply and operate different designs of catalytic sensors. With so many possibilities, the system can easily be tailored to suit your individual application needs. Easy maintenance saves time and money Maintenance of the 4 – 20 mA transmitters is very easy. A one-man calibration or replacement of the sensors can be done without further precautions, even in classified areas. Accessories A range of wall-mount cabinets for a maximum of 5, 8 or 32 controllers as well as a 19”-carrier, ensure an easy professional installation. -20 - +60 °C

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The EndoInjector™ is a precise gas mixing / control system for endothermic gas generators. It incorporates a patented fuel injection design that utilizes electronic flow measurement and precise ratio control to consistently provide the ideal gas mixture for high quality endo gas generation. The fuel injection design automatically delivers gas mixture on demand, providing only as much endothermic gas as furnaces require to reduce operating costs and eliminate gas waste. EndoInjector™ typically pays for itself in less than 1 year. The ExoInjector™ is designed specifically for exothermic gas generators. While similar in concept, the ExoInjector™ differs from the EndoInjector™ in that it comes in modified mechanical versions to accommodate pre-mix or nozzle-mix burners with a custom HMI software that allows for predefined ratio set points for burner ignition, rich exo, and lean exothermic gas. The system can be modified to provide hydrogen content control and water vapor monitoring.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The RCV Plus™ Gas Mixing System is a combination of flow meters specifically designed to monitor and control the ratio of two gases. It consists of an RCV Plus™ and a FLO-TRONIC Plus™. The RCV Plus™ utilizes a micro-processor that continuously compares a preset ratio to the real-time ratio of the two gas flows, as measured by the FLO-TRONIC Plus™, and the ratio control valve itself. Using a stepper motor, the RCV Plus™ continuously adjusts the flow metering needle-valve to precisely maintain the preset gas ratio. The real-time ratio is continuously displayed on the LCD screen of the RCV Plus™. Included in the RCV Plus™ is an optional input for the addition of a trim gas, which is frequently used for process control. Trim gas addition is additive to the ratio. When trim gas is used, the continuously displayed real-time ratio then includes the trim gas addition.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The EndoFlex™ is an advanced endothermic gas generators with an extensive list of features to improve gas reaction efficiency while also providing sensors to diagnose most common gas generation issues before they become problems. FEATURES & BENEFITS • Lower operating costs and emissions waste from 20-80% of generator capacity • Automatic endothermic gas pressure control eliminates regulator adjustments • Multi-retort design reduces cost, allowing for quick replacement of components • Separate methane sensors provide data for scheduling retort burnout • Filter change indicator improves system effi ciency and operation time • Built-in software for ease of scheduling, maintenance, and paperless data logging

Request for a quote

EWM AG

Germany

— MIG/MAG pulse welding machine with optimised synergic characteristics for welding steel — Pulsed MIG/MAG welding, MIG/MAG welding, MMA welding and gouging — Significantly less spatter formation and therefore less finishing work thanks to the pulse function — Welding with solid wire and flux cored wire — Drive 4X Steel: Connection socket for electrode holder on the wire feeder as standard — Drive 4X Steel D200: Adjustment of the gas quantity directly on the wire feeder via the gas control valve as standard. — Factory-fit option: Extra gas valve for increased safety — Infinitely adjustable arc dynamics (choke effect) — Adjustable start and end-crater functions — Synergic or manual welding operation

Request for a quote

AQUAMETRO OIL & MARINE GMBH

Germany

Your benefits Optimum combustion efficiency Easy of mind due to long term experience and marine type approvals Competitive price Adaptable to own requirements No need for recalibration Areas of application The measurement and control of fuel oil viscosity is a known requirement within the marine and diesel engine industries. The HFVM measures liquid viscosity, density, and temperature in aggressive environments. These meters use vibrating fork technology for reliable direct-insertion measurement. HFVMs provide Heavy Fuel Oil (HFO)/Marine Gas Oil (MGO) combustion control, and oil-fired heater and boiler control.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station to review the gas detection devices. The control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 is possible. All gases can be connected to 1 liter aluminum compressed gas cans. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for revising gas detection devices. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. Rather than a pressure gauge, the PS 403-U has a vacuum manometer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Hot gases are required for dierent industrial processes – particularly when it is necessary to heat drying systems directly. Büttner's line burners have been designed for robust and ecient use in the production of hot gases and are fuelled with natural gas. Gas line burners have been tried and tested in the wood processing, cement, mill-construction and many other industries across the world. Büttner's line gas burners are extremely robust, safe and maintenance-friendly Key features: Performance range from 0.8 MW to 48 MW Service-friendly modular design The burner ramps may be equipped with several gas-control sub-trains that may be individually deac Very low pressure losses across the burner (approximately 2 mbar) result in energy savings of more th

Request for a quoteResults for

Gas control - Import exportNumber of results

39 ProductsCountries

Category

- Welding, soldering and brazing - equipment and supplies (4)

- Gas detector-controllers (2)

- Testing equipment (2)

- Flow meters (2)

- Packing and packaging - machinery and equipment (1)

- Food Processing (1)

- Plasma cutting machines (1)

- Boilermaking, heavy (1)

- Boilers, industrial (1)

- Crate packing machinery (1)

- Energy - production plants and equipment (1)

- Gas detectors (1)

- Gas filters (1)

- Gas mixtures (1)

- Import-export - steels and metals (1)

- Laboratory equipment and instruments (1)

- Measurement - Equipment & Instruments (1)

- Smelting furnaces (1)

- Steel (1)

- Steels and metals - welding and brazing (1)