- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas burners

Results for

Gas burners - Import export

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

The new generation of a proven series. The CERTUSS Universal 500 - 1800 TC steam generators are characterized by the immediate modulating output adjustment and the simplified operation. TC is the abbreviation for Touch Control. CERTUSS steam generators of the Universal series with oil, natural-gas or combination combustion are manufactured in four sizes. Individually or combined they meet all requirements and dispose of lightened official installation conditions in Germany. Combustion: Oil, gas or a combination Steam output optionally 500 - 600 kg/h 700 - 850 kg/h 1,000 - 1,300 kg/h 1,500 - 1,800 kg/h

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

for gas burners meeting DIN 30665*spiraling stainless steel wire core (buckling resistance)*working pressure up to 100 mbar

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For mounting screwed connections, e.g. at combustion engines, threads on pipe fittings, flange joints and fittings of superheated steam lines, exhaust pipe and combustion chamber screwed connections, gas and oil burner mounting bolts To prevent burning together, seizing or rusting-on of screwed connections at water influence Suitable for brake systems of vehicles Advantages and benefits Excellently suited for preventing binding of threads exposed to high temperatures, corrosive environments and moisture Highly effective due to high level of pressure absorption Excellent corrosion protection Absolutely resistant to fresh water and sea water Extremely adhesive No classification according to (EG) No. 1272/2008 For best adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first (for example, with a wire brush) and then with OKS 2610/OKS 2611 universal cleaning agent. Use a brush, spatula or similar

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembling screw threaded connections subjected to high temperatures and corrosive influences Screwed connections at pipe fittings, flange joints and fittings in superheated steam lines Combustion chamber screwed connections and mounting bolts of gas and oil burners Screwed connections at combustion engines, exhaust systems, silencers and exhaust gas pipe connections Advantages and benefits Allows reliable non-destructive dismantling even after longer operating period under high operating and ambient temperatures Provides an optimal ratio of screw pretension and tightening torque Electrically conductive To achieve optimal adhesion clean the thread or the sliding surface first mechanically and then with OKS 2610/OKS 2611 universal cleaner to remove soiling as well as any lubricant residues. Use a brush, spatula or similar to apply a sufficient amount of paste to the head or nut contact surface and to the thread. Spray on evenly OKS 241 spray. The paste will also act as a sealant.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembling screw threaded connections subjected to high temperatures and corrosive influences Screwed connections at pipe fittings, flange joints and fittings in superheated steam lines Combustion chamber screwed connections and mounting bolts of gas and oil burners Screwed connections at combustion engines, exhaust systems, silencers and exhaust gas pipe connections Advantages and benefits Allows reliable non-destructive dismantling even after longer operating period under high operating and ambient temperatures Provides an optimal ratio of screw pretension and tightening torque Electrically conductive Also available as spray version OKS 241 To achieve optimal adhesion clean the thread or the sliding surface first mechanically and then with OKS 2610/OKS 2611 universal cleaner to remove soiling as well as any lubricant residues. Use a brush, spatula or similar to apply a sufficient amount of paste to the head or nut contact surface and to the thread.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Piping and hoses, for example steel bottles, compressors, breathing devices, oxyacetylene gas and inert-gas arc welding devices and burners Fittings, flanges, valves, screwed connections, soldered and welded connections of pressure gas systems and lines Suitable for compressed air, refrigerant, acetylene, butane, natural gas, carbon dioxide, gaseous oxygen, propane, town gas, nitrogen, hydrogen and, ammonia Advantages and benefits Acts non-corrosive Allows direct visual inspection of the leakage point through bubble formation Tested by the DVGW in accordance with DIN EN 14291 Suitable for spraying overhead

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Piping and hoses, for example steel bottles, compressors, breathing devices, oxyacetylene gas and inert-gas arc welding devices and burners Fittings, flanges, valves, screwed connections, soldered and welded connections of pressure gas systems and lines Suitable for compressed air, refrigerant, acetylene, butane, natural gas, carbon dioxide, gaseous oxygen, propane, town gas, nitrogen, hydrogen and, ammonia Advantages and benefits Acts non-corrosive Allows direct visual inspection of the leakage point through bubble formation Also available as spray version OKS 2801 Spray version tested by the DVGW in accordance with DIN EN 14291 Spray version suitable for spraying overhead

Request for a quote

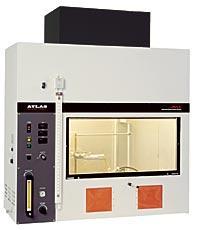

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas HVUL2 Horizontal Vertical Flame Chamber is designed for the flammability testing of plastic materials used in consumer electric devices and appliances. The chamber is constructed of stainless steel with a black interior and large sliding window for easy viewing. The HVUL2 includes a fully adjustable specimen support and a precision metered gas burner. Three digital timers with remote control are mounted on the inside back wall of the chamber, allowing for precise and simplified operation. Burner angle adjustable to 0º, 20º, 45º Flexible iris hand access ports Remote burner positioning Sliding tempered glass viewing window Removable burner carriage assembly Flexible laboratory fixturing Interior light Digital timers located in line of sight with specimen Digital timers with resolution of 0.1 sec Remote control with push button reset for in-chamber event timing. Electrical gas shut-off solenoid Gas control system Flame confirmation kit (ASTM D5207) Black interior finish Performs all UL 94 tests (Except Section 10.0 Radiant Panel Test) Bench top chamber (Volume greater than 0.75 m 3) Tirril Burner Multi-directional specimen and burner positioning apparatus Quick release mount for burner during manual operation Large sliding, tempered-glass window for test viewing Exhaust blower (1/3 hp) with variable speed control (580 cfm in free air) Sliding damper for draft free chamber Manometer/pressure gauge, 300 mm Four flame height and sample gauges Interior Dimensions: 122 cm (48'') W x 112 cm (44'') H x 60 cm (23.5'') D Exterior Dimensions: 122 cm (48'') W x 140 cm (55'') H x 61 cm (24'') D Bench Weight: 163 kg (360 lbs) Simple burner angle adjustment (0°, 20°, 45°) Specimen holders for all five Bunsen burner tests Digital timers for specimen test duration, 0.1 sec. resolution Remote control with push button reset for in-chamber event timing Quick release mount for burner during manual operation Hand access openings with irises for closed window access

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Hot gases are required for dierent industrial processes – particularly when it is necessary to heat drying systems directly. Büttner's line burners have been designed for robust and ecient use in the production of hot gases and are fuelled with natural gas. Gas line burners have been tried and tested in the wood processing, cement, mill-construction and many other industries across the world. Büttner's line gas burners are extremely robust, safe and maintenance-friendly Key features: Performance range from 0.8 MW to 48 MW Service-friendly modular design The burner ramps may be equipped with several gas-control sub-trains that may be individually deac Very low pressure losses across the burner (approximately 2 mbar) result in energy savings of more th

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Büttner's fash-tube dryers are most versatile and extremely ecient. The dryer systems are used for drying material having high levels of surface moisture or a specic surface area. They are, for example, used to pre-dry wood akes before they are conveyed into drum dryers. Flash tube dryers are also used as the principal dryers for drying bres to be used in MDF production. For many years Büttner's ash tube dryers have been in operation successfully in many dierent industrial sectors all over the world Features Water evaporation of up to more than 70 t/h per unit depending on the product Drying within just a few seconds, the material is then already mechanically separated and conveyed to the downstream drum dryer. Flash tube dryers may be heated in many dierent ways, for example: Flue gas from grate ring Büttner gas line burners Hot gas from gas turbines or gas motors Indirectly by heat exchangers for steam or thermal oil Any combination of the heating methods mentioned above

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Prior to coating plastic workpieces, they can be flame heated using a gas burner to improve adherence. This is not a heat treatment but rather a selective utilisation of the chemical effect of the gas flame. Naturally, we also offer further pretreatment equipment, such as the plasma treatment for example. During flame heating, the surface is briefly subjected to the direct effect of a gas flame fed with extra oxygen. This causes the breaking of molecular bonds in the surface of the substrate to be treated, and the binding of active ions, mainly OH and COOH groups existing in the flame. In this manner, polar groups, enabling the secure bonding of printing inks, lacquers/paints, adhesives, etc. are created in the originally nonpolar material. Due to the formation of polar groups, the surface energy of the treated substrate increases to a measurable amount.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

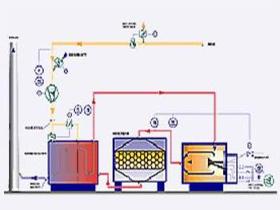

Under defined conditions, the catalytic thermal oxidizer (CTO) is an economical alternative for cleaning organic air pollutants (including VOCs). The system has proven to be particularly efficient when handling identifiable and consistent pollutant loads. In general, exhaust gases containing silicon and phosphorous cannot be treated. Under defined conditions, the Catalytic Thermal Oxidizer (CTO) is an economical alternative for cleaning organic air pollutants. The procedure is based upon the fact that under suitable conditions, even low amounts of volatile pollutants can be burnt without producing residue. This process would have required a high amount of heat energy. Therefore a catalyser and a heat exchanger are installed. The tubular heat exchanger installed behind the catalyser uses as much energy from the hot clean gases as possible in order to heat up the cold raw gases. The job of the catalyser is to decrease the amount of energy required to convert the pollutants without being depleted during the reaction. The raw gas loaded with pollutants is then forced into the heat exchangers of the CTO by the process fan. Here the raw gas is pre-heated by the hot clean gas. When required the burner heats up the exhaust gas further in the combustion chamber to the ignition temperature of the catalyser. In the catalyser the pollutants are converted into non-polluting CO2 and H20 vapour. After the catalyser, the clean gas is forced into the heat exchanger tubes. Along the way through the heat exchanger tubes the raw gases is heated and cooled. Eventually the clean gas leaves the system via the clean gas socket.

Request for a quote

WÖHLER GMBH

Germany

As robust as cast iron, but as easy to operate as a smartphone that’s what Wöhler’s new flue gas analyzer feels like in your hand. Appropriately, the advantages are equally substantial: A tip with your finger on the Wöhler A 550 is all that is required to perform analyses, inspections and settings on residential and commercial appliances. The flue gas analyzer is equipped with coded connections for the 4 Pa test and even »NEW AND UNIQUE« a wood moisture content measurement function to VDI Guideline 4206 (VDI = Association of German Engineers). * Effective condensate protection * Automatic CO clean out pump protects CO sensor (Wöhler A 550) * 4-filter technology – easily accessible * Analyzer and sensor diagnostics * Sensor replacement – user-friendly * Rechargeable battery operating time: more than 12 h with Lithium Ion power * Hose assembly – robust and flexible

Request for a quote

THERMO-CONTROL KÖRTVÉLYESSY GMBH

Germany

Oxygen combination sensor with built-in type S thermocouple and threaded connection. Applications (examples): The sensor is used, for example, in carburizing plants to control the C-level, in forging furnaces to control the air supply of the gas burners, or in the atmosphere of crematoria. The sensor is not heated. Therefore, a minimum operating temperature of 500 ° C is required. Material Order: Assembly: Connection head form A with M20x1.5 cable gland Pressure range: Ambient pressure up to 2 bar Temperature range: 520 ° C to 1300 ° C Connection: thread G3 / 4 "DIN 228 / thread G1" DIN 228 Thermocouple: 1 x Type S PtRh (10%) - Pt DIN EN 60584-1, Class 1 Protection tube: Ø 17mm Thermowell material: 99.7% Al2O3 Continuous zirconia tube as electrolyte Reference air connection: Ø 6,0 nozzle max 10 liters / hour Purge air connection: Ø 6,0 nozzle max 200 liters / hour Gas electrode: spiral / helix platinum wire Air electrode: spiral platinum wire

Request for a quoteResults for

Gas burners - Import exportNumber of results

15 ProductsCountries

Company type