- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas boilers

Results for

Gas boilers - Import export

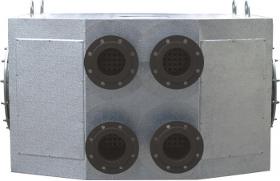

BORSIG GMBH

Germany

BORSIG supplies synthesis gas boilers for gas pressures up to 350 bar (35,000 kPa) and steam pressures up to 160 bar (16,000 kPa). They are used in the synthesis gas loop of ammonia plants. The boilers are equipped with U-tubes and can be mounted both in the vertical as well as in the horizontal positions. With both designs, the steam drum can be integrated into the boiler if requested by the customer. At the same time, a feed water pre-heater can be installed in the boiler when required.

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems up to 1000 kW. With booster technology for an increase lifetime. The Premium Line consists of 6 different units for the neutralisation of acidic condensates of gas condensing heating units up t0 1000 kW Neutrakon® N35 – up to 35 kW Neutrakon® N65 – up to 65 kW Neutrakon® N170B - up to 170 kW Neutrakon® N300B - up to 300 kW Neutrakon® N650B - up to 650 kW Neutrakon® N1000B - up to 1000 kW

Request for a quote

MOMMERTZ GMBH

Germany

The neutralisation unit Neutrakon® is suitable for the neutralisation (increase of the pH value above 6,5) of acidic condensates of gas condensing boilers (heat exchangers) and/or flue gas systems The Neutrakon® Classic Line consists of 4 different units for the neutralisation of acidic condensates of gas condensing heating units from 25 – 300 kW Neutrakon® 01/25 – up to 35 kW Neutrakon® 02/50 – up to 65 kW Neutrakon® 03/150 - up to 150 kW Neutrakon® 04/300 - up to 300 kW

Request for a quote

BORSIG GMBH

Germany

BORSIG manufactures reformed gas waste heat boilers for more than 50 years. We supply reformed gas waste heat boilers for gas inlet temperatures of up to 1,200°C and steam pressures of up to 160 bar (16,000 kPa) for petrochemical industry (ammonia plants, methanol plants, hydrogen plants, ethylene plants, styrene plants, MTBE plants, oxo-alcohol plants, direct reduction iron plants, coas gasification plants, gas to liquid plants, and others. Every reformed gas waste heat boiler is designed and manufactured exactly in accordance with the customer´s individual requirements. BORSIG offers two different designs: 1. Reformed gas waste heat boilers with BORSIG´s thin stiffened tube sheet design 2. Reformed gas waste heat boilers with thin flexible tube sheet design.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Extreme-temperature grease on the basis of perfluorinated polyether oils (PFPE) for use in food processing technology at maximum loads and temperatures. Grease lubrication of friction and rolling bearings in the high-temperature range Application, for example at tunnel kiln cars, baking, burn-in and drying furnaces, hot gas units, reaction vessels, boiler plants, roller and conveyor rollers in continuous furnaces, etc. Use at bearing points under influence of chemicals/fuel Advantages and benefits Maximum water and steam resistance Extraordinary resistance to chemicals, for example to solvents, for example benzene, benzol, acetone, trichloroethylene and against inorganic acids, such as sulphuric acid, hydrochloric acid and nitric acid as well as stearic acids, alcohols and halogens Excellent plastic and elastomer compatibility For long-term lubrication of lubrication points subjected to high pressure up to 300°C

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With the effective recovery of flue gas heat, you can save up to 14% on fuel and, at the same time, reduce emissions. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 14% when using an additional downstream condensing heat exchanger — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting — Feed water cooling or combustion air preheating as alternatives to the condensing heat exchanger

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quoteResults for

Gas boilers - Import exportNumber of results

8 ProductsCompany type