- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- friction

Results for

Friction - Import export

THERMA THERMOFÜHLER GMBH

Germany

With the Therma friction thermocouple you can determine the surface temperature of the brakes while driving. Attaching the mounting adapter puts uniform pressure on the brake disc through the spring-loaded sensor by using a bayonet cap. That perfectly compensates movements caused by centrifugal force and vibrations as well as the volume decrease caused by disc wear while ensuring a valid measurement. The brake disc friction sensor measures the surface temperature of the brake disc. It imparts important insights about the temperature development. That enables an indication about the brake line, intake and temperature radiation. A brake disc that becomes too hot during a race massively loses its effectiveness and deceleration to the accustomed and optimal degree is no longer possible. If the temperature is too high, the brake pads start gassing on top of that.

Request for a quote

FESSMANN GMBH UND CO KG

Germany

The RATIOFRICTION friction smoke generator convinces not only with its low operating costs, but in particular with its unique, mild smoke aroma. Variable smoke intervals also permit flexible adjustment of the smoke intensity to the requirements of your specific product. The patented friction procedure reduces consumption of smoking agents and considerably extends the friction wheel's service life without any sharpening of the cutting teeth. Mild smoke aroma Automatic cleaning aid Variable smoke intensities by adjustable smoking intervals Automatic cleaning aid Costefficient smoking material, beechwood beams quality II, 80 × 80 × 800 mm or 80 × 100 × 950 mm Low consumption Very low noise Unparalleled service life of the friction wheel Less power consumption of the motor than in conventional systems Including a magazine for spare beams

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of plain and rolling bearings at high temperatures, e.g. in painting and drying ovens, converters, pouring ladles, heating systems, hot-air fans, charging cranes, vulcanising systems and electric motors Advantages and benefits Excellently suited for long-term lubrication of grease lubricating points subject to high-temperature loading Highly effective due to optimum solid lubricant formula Broad range of uses above normal grease performance areas Reduced maintenance and lubricant costs due to possible safety lubrication Drip-free hot bearing grease for long-term and safety lubrication in a broad temperature range For best results clean the lubricating point carefully. Clean with solvents like OKS 2610/OKS 2611 Universal Cleaner. Remove the corrosion protection ahead of the initial filling. Fill the bearings in a way that all the functional surfaces for sure get the grease.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

This coating system is mainly used for the coating of cold rolled strip, but can also be applied to other metals. It is applied in the last processing step and enables a special gliding ability and heat resistance on coated surfaces.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Castrol Syntrans 75W-85 is a special fully synthetic manual transmission oil for commercial vehicles. With Castrol Syntrans 75W-85 it is possible to significantly extend the existing oil change times (observe the manufacturer's instructions). In conjunction with Castrol synthetic technology, Castrol Syntrans sets standards in terms of transmission life, economy and shifting comfort. Advantages -Fuel savings thanks to smooth running properties -Excellent wear protection -Reduces or eliminates shift hooks and noise -Excellent shear stability and aging resistance -Easy shifting at low temperatures -Extremely thermally resistant, therefore best protection in extreme use Specifications API GL-4 Volvo Transmission Oil 97307: 006 MB -Release 235.4 Eaton 500000km drain Europe (service bulletin 2273)

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of rolling and plain bearings subject to very heavy loading Protection of bearings against harmful impurities Protection against corrosion, maintenance of lubricating effect, even when exposed to large quantities of water Advantages and benefits Excellently suited as a high-performance lubricating grease due to special EP properties and solid lubricants The high base oil viscosity, with a stable soap basis even when exposed to water, results in a particular suitability for heavily loaded, slow-running bearings even with impact loading Good emergency running properties due to solid lubricants

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

in BMW manual transmissions . Application Excellent overload protection for highly stressed sequential BMW Motorsport transmissions (SMG 1 and 2) in M vehicles. Best shiftability in the ZF 6-speed manual transmission of the Land Rover Discovery III (LR3). Can also be used excellently in the VW Touareg manual transmission according to VW part number G 052 798. Advantages -Excellent wear protection properties protect highly stressed transmission components -Very good low-temperature flow properties ensure good shiftability at low temperatures -High shear stability offers constant viscosity-temperature behavior over the entire -Excellent thermal and oxidative stability prevents deposits and leads to longer specifications API GL-4 ZF TE-ML 11

Request for a quote

AAAGILER GMBH

Germany

Surface treatment with laser with a broad spectrum of applications (improved thermal conductivity, anti-icing / freezing, anti-friction, anti-wear, lubrication, anti-microbial, reduced electrical resistance e.g. for connectors, holograms, product protection, logos, wettability, increase surface area by up to 280% ...). Can be used for metal (steel, aluminum, titanium) polymers / plastics (e.g. polycarbonate), composite material and ceramics

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

When changing the oil, it is important to use the correct oil. And selecting the right product is becoming increasingly complicated. Modern engines in passenger cars and commercial vehicles are becoming ever smaller and more powerful. Manufacturers are prescribing complex synthetic oils that can withstand higher engine pressure and at the same time achieve the desired fuel economy. We do not leave you alone in deciding on the optimum oil and advise you on selecting the right engine oil from our product portfolio.

Request for a quote

AAAGILER GMBH

Germany

Surface treatment with laser with a broad spectrum of applications (improved thermal conductivity, anti-icing / freezing, anti-friction, anti-wear, lubrication, anti-microbial, reduced electrical resistance e.g. for connectors, holograms, product protection, logos, wettability, increase surface area by up to 280% ...). Can be used for metal (steel, aluminum, titanium) polymers / plastics (e.g. polycarbonate), composite material and ceramics

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of the most varied materials sliding on top of or rubbing against each other (such as metals, wood, ceramic, rubber, and also adhesives or paintable plastics) Anti-stick coating of seals or sealing surfaces of all kinds to prevent sticking-on To cure the squeaking noises of soft on hard materials For water-repellent impregnation of absorbent materials Separating film in cast resin applications Advantages and benefits Dry, non-soiling film Highly effective due to good adhesion to prepared substrates Colourless and odourless low-friction coating with non-stick properties Prevents frictional corrosion Dries at room temperature

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution The mobile testing device may be mounted directly on the wheel nuts on any wheel on the car. The height and tilt adjustment allows optimal orientation at the wheel. Additionally, it is still supported by three proximity sensors. The evaluation and control of the testing device accepts a laptop. For easy transport, the device can be disassembled in a few steps. Curve recording and analysis via notebook. The complete unit is height adjustable via a scissors system. This can also be adapted to different shaft height.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

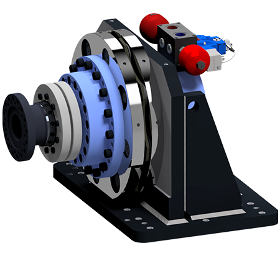

Like all Hense rotary vane motors, rotary vane motors in the HSS series are designed according to the rotary vane principle. The drive shaft has axial and radial plain bearings in coated bushes. The coating used is tribologically optimized and ensures low wear. Sufficient lubrication of the bearing points is ensured by the supplied hydraulic oil. To reduce the internal friction of the motor, the hydraulic separation of the working chambers in this series is partly achieved by means of pressure and viscosity-dependent throttle sections. HSS motors are ideal for generating oscillating swivel movements in the frequency range with small angular amplitudes in controlled systems. The HSS series is therefore recommended for use whenever semi-dynamic torsion tests need to be carried out reliably and cost-effectively.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

DPFR-004 Customized Solution for friction measurement of transmission A hand-held enclosure with integrated torque transducer, start buttons and 1 display for torque andf speed. Is used to the friction torque of tapered roller bearing set or monitor. portable Safety circuit by two-hand operation Constant load independent test speed

Request for a quote

FATH GMBH

Germany

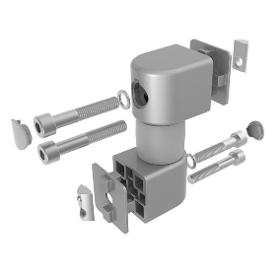

Description: Connection joint with friction for the creation of system arms using profile pieces; pivotable 360°; friction joint can be attached lateral, transverse, or on the face of the profile; if attached on the front face, the core hole of the respective profile must be M8 threaded (min. 15 mm deep) Material: Housing: Aluminum die-cast Cover ring: Plastic Inserts: Steel Friction shaft: Steel Cover caps: Plastic Screws: Steel Washers: Steel Centering plates: Aluminum die-cast T-slot nuts: Steel Surface: Housing: Laquered Centering plates: Laquered Screws: Zinc plated Washers: Zinc plated T-slot nuts: Zinc plated Color: Housing: Alu color Cover ring: Gray ≈ RAL 7042 Cover caps: Gray ≈ RAL 7042 Centering plates: Alu color Set: Various Sets available - Please contact us for Details Pack Quantity: 1 piece/set

Request for a quote

FATH GMBH

Germany

System hinge for panel elements and aluminium profiles 3o and 40, with cover caps Positioning Function: to hold a door open at an angle at 85° or 175° or to keep it securely closed Adjustable friction: to hold a door open at an angle at any angle; infinitely variable from 0 - 5 Nm hinge moment; also supports lightweight doors Material: PA plastic, glass-fibre reinforced Bolt: depending on version, partly stainless steel Colour: black Fastening: From the front using M6 screws, from the back using hexagon nuts and bolts Extras: electrostatically discharging (ESD conductive), other sizes, different blades, other colours on request

Request for a quote

BEHA INNOVATION GMBH

Germany

The unique friction welding machine RS02 is the professional tool for the maintenance operator and also the fastest and most reliable way of welding belt profiles. Constantly good quality connections are produced in a few seconds with repeatable accuracy due to fixed welding parameters. Welding clamping jaws tuned to the respective profile ensure reliable clamping and perfect alignment of the profile. Thanks to its handy type of construction, the friction welding machine can even be used in narrow space conditions for comfortable welding. The recently developed battery version is now available to ensure unlimited freedom of motion.

Request for a quote

BEHA INNOVATION GMBH

Germany

BEHAbelt offers a comprehensive portfolio of monolithic elastic conveyor belts for various industrial applications. Due to the steadily growing automation of industrial production processes and processing machines, new challenges are constantly arising. Only when all machine components keep pace with your product characteristics will real progress be made in terms of efficiency, capacity and safety. BEHAbelt’s conveyor belts and belting are purely monolithic; i.e. they are made entirely of polyurethane and do not require a fabric insert. Thus, these belts allow for service life improvements and significantly minimize the risks in terms of food contamination that can occur due to stock separation or fraying.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

RINGFEDER® Friction Springs consist of separate inner and outer mating tapered rings which stack together to form a column according to the customer’s wish. These units are repeatedly loaded 100% before delivery. Hereby the absolute functionality is ensured. Features of RINGFEDER ® Friction Springs RINGFEDER ® Friction Springs are employed in the engineering sector when high kinetic energies must be absorbed or when springs of relatively compact dimensions are required for high forces. RINGFEDER ® Friction Springs have multitude features in opposite to other damping systems: High spring work combined with low weight and volume: As RINGFEDER ® Friction Springs completely utilise the material of which they are made only a minimum of dimensions and weight are required. The decisive parameter here is therefore the spring work. High Damping Potential: The damping of RINGFEDER ® Friction Springs is standard with 66% wherewith the energy will be soon absorbed and resonances complete...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

RINGFEDER Friction Springs can also be supplied in customized buffer versions. Features of RINGFEDER ® Friction Springs RINGFEDER ® Friction Springs are employed in the engineering sector when high kinetic energies must be absorbed or when springs of relatively compact dimensions are required for high forces. Friction springs RINGFEDER ® have multitude features in opposite to other damping systems: High spring work combined with low weight and volume: As RINGFEDER ® Friction Springs completely utilise the material of which they are made only a minimum of dimensions and weight are required. The decisive parameter here is therefore the spring work. High Damping Potential: The damping of Friction Springs RINGFEDER ® is standard with 66% wherewith the energy will be soon absorbed and resonances complete disabled. Variations are possible with different greases. Overload-safe in blocked position:RINGFEDER ® Friction Spring are generally designed to “block”, so it is therefore ensured...

Request for a quote

TAS SCHÄFER GMBH

Germany

The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column is shortened. This has the effect that the outer rings stretch and the inner rings reduce in diameter. As a result of the friction arising on the conical surfaces, the introduced energy is absorbed and converted into heat which is to be removed. Resonance effects are suppressed completely. The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column...

Request for a quote

ERC ADDITIV GMBH

Germany

ERC motor oil power additive with friction modifier reduces friction, wear, and sediments. It also improves the oil supply and stabilises viscosity with reduced oil sludge formation. All these features contribute to improved engine performance. THE EFFECT With the ageing of oil in everyday engine operation, build-up and clogging of filters and oil passages occur. ERC motor oil power additive removes this deposits, improves the oil supply, and protects metal surfaces. THE ADVANTAGES AT A GLANCE - Reduces friction and wear and increases engine performance - Cleans build-up off the engine and oil passages - Safeguards and improves oil supply - Reduces noises and stabilises oil pressure - Protects against oil ageing and corrosion - Reduces fuel consumption and exhaust gases - Extends engine service life

Request for a quote

ERC ADDITIV GMBH

Germany

THE EFFECT Fluctuating quality of fuel can impair performance and consumption. Coking on injection nozzles raises fuel consumption. The high pressures of modern injection pumps require outstanding fuel lubricating properties. ERC Diesel Power Additive improves ignition behavior (rise in cetane count), cleans and keeps injection nozzles clean, and the lubricity improver improves the lubricating properties of diesel, thus providing optimal protection from wear. ERC Diesel Power Additive contains a Performance Packet for stabilizing ageing or oxidation and cold-protection (in winter operation). THE ADVANTAGES AT A GLANCE: - eases cold start, boosts engine output - improves lubricating properties of diesel fuel and works against wear - cleans and keeps the fuel system and injection nozzles clean - protects against corrosion in fuel tanks, fuel supply lines and engine interior - results in lowers fuel consumption clean burning and reduction in emissions such as rust, CO etc.

Request for a quote

ERC ADDITIV GMBH

Germany

- Reduced friction - Reduced fuel consumption - Reduced wear on parts THE EFFECT Friction leads to wear and increases fuel consumption. ERC Gear Oil Power Additive is highly effective at reducing friction and wear by laying flake-like MoS2 particles on the metal surface; the particles then smoothly slide over each other on their parallel surfaces, reducing wear on the metal parts. Additional polymers add to the low-friction dynamics. THE ADVANTAGES AT A GLANCE: - Special product with MoS2 low friction formula - Highly effective at reducing friction and wear - Decreases fuel consumption - Decreases frequency of repairs - Ensures easy gear change and noise reduction - Increases endurance of the gearbox oil base and enhances dry-running properties

Request for a quoteResults for

Friction - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Hinges (4)

- Plain bearings (4)

- Lubricants, industrial (3)

- Silicones (3)

- Electric motors and parts (2)

- Laser printing (2)

- Measurement and control instruments (2)

- Conveyor belts (1)

- Cooking and smoke-curing equipment for delicatessens (1)

- Engines & Parts (1)

- Fuels, diesel (1)

- Gears (1)

- Inductive sensors (1)

- Industrial valves, operating equipment (1)

- Mechanical clutches (1)

- Seals (1)

- Seals - custom packaging (1)

- Steels and metals - surface treatment and coating (1)

- Welding, electric - equipment and supplies (1)