- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spray nozzles

Results for

Spray nozzles - Import export

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The innovative design is a new, higher standard in terms of features, ease-of-use, accuracy and safety as compared to competitive fluorescent UV devices. - Proven performance matches or exceeds other brands - Modern touch screen interface in several languages - Remote ethernet data acquisition - Unsurpassed safety compliance - Recirculating spray water option - Plus many other exclusive user-friendly features Fluorescent UV lamps (8) - 40 W (UVA 340, UVB 313, UVA 351) Black Panel Temperature (BPT) Control Door safety and over-temperature shutoff CE compliance and UL & CSA certified Specimen Holders Touch screen display Irradiance calibration safety access ports Ergonomically designed specimen retaining rings Recirculating spray water (12) specimen spray nozzles Hand-held irradiance calibrator Data acquisition program via Ethernet Stacking kit Irradiance control (340 nm, 313 nm, 351 nm) Customer-specified spray nozzles

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Testing of assembled components provides an advantage for evaluating the combination of potentially incompatible materials. An Atlas Walk-in allows testing of oversized samples and assembled components, such as motorcycles, electrical panels for outdoor use, household appliances, vehicle seats, pressurized cyclinders, bicycles, military items, ranch and farm machinery, snowmobiles, window/door assemblies and much more. Installing MH (metal halide) or MHG (metal halide global) luminaries in Atlas Walk-in chambers increases the testing capabilities for any lab. NOW, entire assemblies and oversize samples can be tested for UV resistance, corrosion and other environmental conditions in the same unit. PlexiglasTM viewing window in door Inside safety latch for door Interior liner with sheet PVC for uniform thickness Raised interior floor to accommodate drainage Floor covered with rubber sheet or plastic mat PlexiglasTM access port Interior light with switch on exterior wall Ambient to 120 °F (49 °C) exposure tone temperature Interior shell of mild steel, primed on both sides Testing Volume: 7,136 Litres - 11,893 Litres (depending on size of chamber) Exposure Zone Dimensions: L x W x H : SF7000 - 6' x 6' x 7' (1.83m x 1.83m x 2.13m) ; SF9500 - 8' x 6' x 7' (2.44m x 1.83m x 2.13m) ; SF12000 - 10' x 6' x 7' (3.05m x 1.83m x 2.13m) External Dimensions: L x W x H: SF7000 - 7' x 7' x 9' (2.13m x 2.13m x 2.74m) ; SF9500 - 9' x 7' x 9' (2.74m x 2.13m x 2.74m) ; SF12000 - 11' x 7' x 9' (3.35m x 2.13m x 2.74m) Sloped ceiling prevents dripping of condensation onto samples Microprocessor-based cycling controls for basic cycling testing Fog stripper, manual operation Timer for bubble tower Precision air regulator Solution spray with multiple nozzles UL approval External condensate collection package High voltage kit (over 460 VAC) High capacity oil & water extractor Custom sizes (extra height / any LxW / drive-in or drive-through with overhead door) and configurations (pass-through electrical/mechanical ports)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

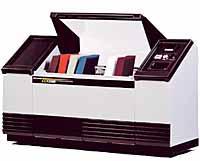

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Basic cyclic tests are used to qualify a coating or material for a specific end use on a pass-fail basis, or determine the probability of corrosion of a specific material. Applications include: Aerospace, Appliances, Automotive, Government, Marine Craft, Paints/Coatings, Research, and Telecommunications. Reinforced fiberglass cabinet, exposure lined with gel coat Solution reservoir - 35 gal (132L) Clear cover with dual magnetic Santoprene gasket (BCX9000 comes with opaque Polypropylene cover) Peaked cover prevents dripping of condensate onto sampl Exposure zone heated by titanium rod heater Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 131 °F (55 °C) - Hight temperature option up to 160 °F (71 °C) Omni-Fog Dispersion Tower or Omni-Fog II Dispersion System, fully adjustable. Built-in support ledges, front and back Wet Bottom Drain Assembly; heated, with auto fill for higher and more uniform humidity (n/a BCX11000) Air-assisted Cover Lifters on BCX9000 and BCX11000 Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) BCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 1.93 x 0.9 x 1.4 m BCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 2.46 x 0.9 x 1.4 m BCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 2.46 x 1.1 x 1.4 m BCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 2.69 x 1.32 x 2.16 m BCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 2.82 x 2.29 x 1.83 m Combination exhaust condenser and wet bottom drain assembly Recorder, 2-pen circular chart, digital display, 7 day, wet bulb and dry bulb Recorder, 6 channel strip chart; 4 temperature probes and air pressure Modem for remote trouble shooting Solution spray, two-nozzle External condensate collection package High voltage kit (over 460 VAC) Gas injection system for SO 2, CO 2, NO x High capacity oil & water extractor Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Air-actuated Cover; required for tests specifying ambient conditions Solution Spray; multiple nozzles (8, 12 or 16) with individual shut-off valves CE, UL CSA Conformance certifica High Temperature System, to operate BCX up to 71ºC / 160ºF BCX2000/BCX3000/BCX4000/BCX9000/BCX11000 SO 2 Injection; for customer-supplied SO2, customer-supplied fume hood recommended Data Recording Software; PC based, sends data to customer's computer

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Spray nozzles - Import exportNumber of results

4 ProductsCountries

Company type

Category