- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- shaft mounting

Results for

Shaft mounting - Import export

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

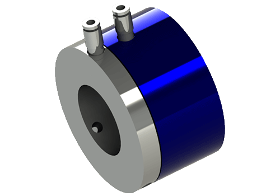

universal useclamping/release elastomer seal lightweight construction small size PRESSURE MAXIMUM 9,0 bar air vacuum TEMPERATURE MAXIMUM 90 °C air

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Unbalance exciters are designed for producing linear motion for medium and large size vibrating machines operating in many industrial processes. The design is engineered for safe operation in continual operation with 100% centrifugal force. In order to archieve higher working moments it is possible to use number of exciters parallel in line. Advantages and benefits powerful drive for higher working moments and wide performance range extremely durable smooth running low maintenance in continual operation economical and long service life low noise level operation Construction and operation mode The AViTEQ unbalance exciters are made of low vibration cast housing. Two shafts mounted in four spherical roller bearings are synchronized by two gears . The mounted on the shaft ends and synchronous forced unbalanced weights are driven by an external drive and produce unidirectional vibrations . The regulation of the static moment can be carried out by some additional weights . Key fi

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRS – Geared agitator with helical geared drive The GRS geared agitator is equipped with a helical geared drive suited for a wide range of applications thanks to shaft lengths of up to 2,000 mm and drive ratings of up to 7.5 kW. The GRS series agitators have a standard output speed of 10 to 500 rpm. The shaft mounting options available include sleeve coupling, flange coupling, quick-change coupling or precision-change coupling. The agitator shafts are balanced for concentric run after assembly of the mixer. Upon request, we supply the GRS series with frequency controlled drive. Depending on the specific mixing task, the GRS can be supplied with matching mixing elements and various seals. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRS geared agitator is equipped with a helical geared drive suited for a wide range of applications thanks to shaft lengths of up to 2,000 mm and drive ratings of up to 7.5 kW. The GRS series agitators have a standard output speed of 10 to 500 rpm. The shaft mounting options available include sleeve coupling, flange coupling, quick-change coupling or precision-change coupling. The agitator shafts are balanced for concentric run after assembly of the mixer. Upon request, we supply the GRS series with frequency controlled drive. Depending on the specific mixing task, the GRS can be supplied with matching mixing elements and various seals. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRV - Geared agitator with variable speed gear unit The GRV series can be used in versatile manner. It is equipped with a mechanically variable speed variation drive with drive ratings of up to 11.0 kW. Furthermore it can be supplied with geared drives that have a standard output speed of between 1 and 1,750 rpm. The speed is adjustable with a hand wheel. The agitator shaft of the GRV series geared agitator is directly mounted on the shaft of the mechanical speed variator or with additional speed reduction (all before mentioned solutions possible). The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRV series can be supplied with matching mixing elements and various seals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRV series can be used in versatile manner. It is equipped with a mechanically variable speed variation drive with drive ratings of up to 11.0 kW. Furthermore it can be supplied with geared drives that have a standard output speed of between 1 and 1,750 rpm. The speed is adjustable with a hand wheel. The agitator shaft of the GRV series geared agitator is directly mounted on the shaft of the mechanical speed variator or with additional speed reduction (all before mentioned solutions possible). The agitator shafts are balanced for concentric run after assembly of the mixer. According to the specific mixing task, the GRV series can be supplied with matching mixing elements and various seals.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

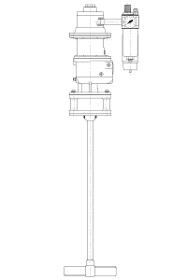

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRP - Pneumatic agitator GRP – pneumatic agitator The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. ((Infotexte)) Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0. The GRP is a pneumatic agitator...

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

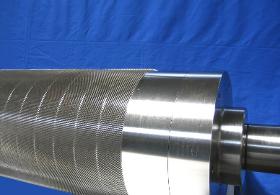

A ready-to-install needle roller on its own shaft or segments to place on the roller for different applications - more details on our homepage! The construction of complete needle or perforation rollers depends on the intended use. Please describe your requirements exactly! Perforation rollers usually consist of individual segments, which are mounted on a shaft or a tube. The mass inertia can be reduced by bearings between the shaft and the tube. In case of driven shafts, the segments can be firmly anchored to this. A sketch of the installation situation with a short description of the requirements helps us to find the optimal solution!

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

TNZ ZCA: Double engagement design with integrated O-ring seal The TSCHAN® TNZ ZCA coupling is a torsionally stiff gear coupling designed to have some backlash and consists of two coupling halves that are connected by fitted bolts. TNZ ZCB: Double engagement design with a bolt-on O-ring carrier for ease of installation Unlike the TNZ ZCA coupling, the TNZ ZCB comes with a bolt-on O-ring carrier which facilitates installation by changing the mounting sequence. For mounting the coupling, unscrew the cover and place it on the shaft. Mount the hub onto the shaft, slide the sleeve onto the hub and fasten the O-ring carrier to the sleeve. This way of mounting is advantageous when large couplings are involved.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Compared to the TNZ ZCA types, the coupling model TNZ ZCAU is equipped with an elongated hub, the length of which can be adapted to the plant requirements. TNZ ZCBU: Double engagement design with a bolt-on O-ring carrier for ease of installation and an elongated universal hub Compared to the model TNZ ZCAU, the TNZ ZCBU coupling is equipped with an O-ring carrier which facilitates installation by changing the mounting sequence. For mounting the coupling, unscrew the cover and place it on the shaft. Mount the hub onto the shaft, slide the sleeve onto the hub and fasten the O-ring carrier to the sleeve. This way of mounting is advantageous when large couplings are involved. Like the model ZCAU, the ZCBU has an elongated hub the length of which can be adapted to the plant requirements.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Unlike the model TNZ ZCAUU, the coupling TNZ ZCA has two elongated hubs the length of which can be adapted to the plant requirements. TNZ ZCBUU: Double engagement design with a bolt-on O-ring carrier for ease of installation and two elongated universal hubs Compared to the TNZ ZCAUU, the coupling model TNZ ZCBUU is equipped with an O-ring carrier which facilitates installation by changing the mounting sequence. For mounting the coupling, unscrew the cover and place it on the shaft. Mount the hub onto the shaft, slide the sleeve onto the hub and fasten the O-ring carrier to the sleeve. This way of mounting is advantageous when large couplings are involved. Like the model ZCAUU, the ZCBUU has two elongated hubs the length of which can be adapted to the plant requirements.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The model TNZ ZCAK is a TNZ ZCA coupling with limited end float. The limitation of the end float serves to axially locate a shaft that is mounted on sleeve bearings. The rotor of an electric motor with sleeve bearings can thus be aligned within a desired tolerance range via the coupling to the bearing of the driven machine so that the rotor remains at its magnetic centre during acceleration of the driving machine. The limitation of the end float constrains the ability to compensate for angular and radial shaft misalignments. TNZ ZCBK: Double engagement design with a bolt-on O-ring carrier and limited end float The model TNZ ZCBK is a TNZ ZCB coupling with limited end float. The limitation of the end float serves to axially locate a shaft that is mounted on sleeve bearings. The rotor of an electric motor with sleeve bearings can thus be aligned within a desired tolerance range via the coupling to the bearing of the driven machine, so that the rotor remains at its magnetic centre during

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The model TNZ ZCAF is composed from the coupling halves of the coupling TNZ ZCA and is complemented by an intermediate shaft and two rigid counter-flanges. If required, the torsional stiffness of the shaft can be tuned to the dynamic behavior of the drive line. In addition, the intermediate shaft, which serves to accommodate longer shaft separations, can be mounted and dismounted radially without having to move the connected machines. TNZ ZCBF: Double engagement design with a bolt-on O-ring carrier for ease of installation, and an intermediate shaft to fulfill specific requirements in terms of torsion spring stiffnesses The model TNZ ZCBF is composed from the coupling halves of the coupling TNZ ZCB and is complemented by an intermediate shaft and two rigid counter-flanges. If required, the torsional stiffness of the shaft can be tuned to the dynamic behavior of the drive line. In addition, the intermediate shaft, which serves to accommodate longer shaft separations, can be mounted and

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The coupling model TNZ ZCAZ is complemented with a spacer that is mounted between the sleeves of a TNZ ZCA coupling by using fitted bolts. The spacer serves to accommodate larger distances between the shafts ends, and can be mounted and dismounted radially without having to move the connected machines. TNZ ZCBZ: Double engagement design with a bolt-on O-ring carrier for ease of installation, and a spacer to accommodate larger shaft separations Unlike the TNZ ZCAZ, the coupling model TNZ ZCBZ is equipped with a bolt-on O-ring carrier which facilitates installation by changing the mounting sequence. The coupling model TNZ ZCBZ is complemented with a spacer that is mounted between the sleeves of a TNZ ZCB coupling by using fitted bolts.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The slit versions are useful in applications requiring the bridging of bigger tolerances and/or higher torques. Stacking of the elements is not recommended. Characteristics Customized application – by varying the number of Locking Elements, size and quantity of clamping screws, the connection can be adapted to fit most applications concerning surface pressures, materials, hub/shaft dimensions and available mounting space. Transmission of high loads – to increase the transmissible torque and axial forces up to 4 Locking Elements can be used in series. Maximum reliability – no matter whether the connection is subjected to static, pulsating, dynamic or intermittent loads. Simple manufacture – shaft and hub are designed without keyway. Apart from this, relatively large tolerances are admissible. Easy adjustability – Locking Elements work without positive connection. So they can be adjusted at any place to any position by following the simple installation and removal...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The slit versions are useful in applications requiring the bridging of bigger tolerances and/or higher torques. Stacking of the elements is not recommended. Characteristics Customized application – by varying the number of Locking Elements, size and quantity of clamping screws, the connection can be adapted to fit most applications concerning surface pressures, materials, hub/shaft dimensions and available mounting space. Transmission of high loads – to increase the transmissible torque and axial forces up to 4 Locking Elements can be used in series. Maximum reliability – no matter whether the connection is subjected to static, pulsating, dynamic or intermittent loads. Simple manufacture – shaft and hub are designed without keyway. Apart from this, relatively large tolerances are admissible. Easy adjustability – Locking Elements work without positive connection. So they can be adjusted at any place to any position by following the simple installation and removal...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RINGFEDER POWER TRANSMISSION GMBH

Germany

Specially small dimensioned self-centering Locking Assembly without axial displacement. As the locking srews are located out of the actual clamping area and the pressures are relatively low, the hub can be designed economically small. Specially small dimensioned self-centering Locking Assembly without axial displacement. As the locking srews are located out of the actual clamping area and the pressures are relatively low, the hub can be designed economically small. Tolerances We recommend the following mounting tolerances Shaft: h8; Hub: H8

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Self-centering 2-piece Locking Assemblies for medium torques. During mounting, minor axial displacement of the hub occurs in opposite direction of the screw head. Due to the small number of screws, cost savings during mounting are ensured. For disassembly only few release screws are required. Self-centering 2-piece Locking Assemblies for medium torques. During mounting, minor axial displacement of the hub occurs in opposite direction of the screw head. Due to the small number of screws, cost savings during mounting are ensured. For disassembly only few release screws are required. Tolerances We recommend the following mounting tolerances Shaft: h8; Hub: H8

Request for a quoteResults for

Shaft mounting - Import exportNumber of results

20 ProductsCountries

Company type